02 12月 Feeder Caster Tip

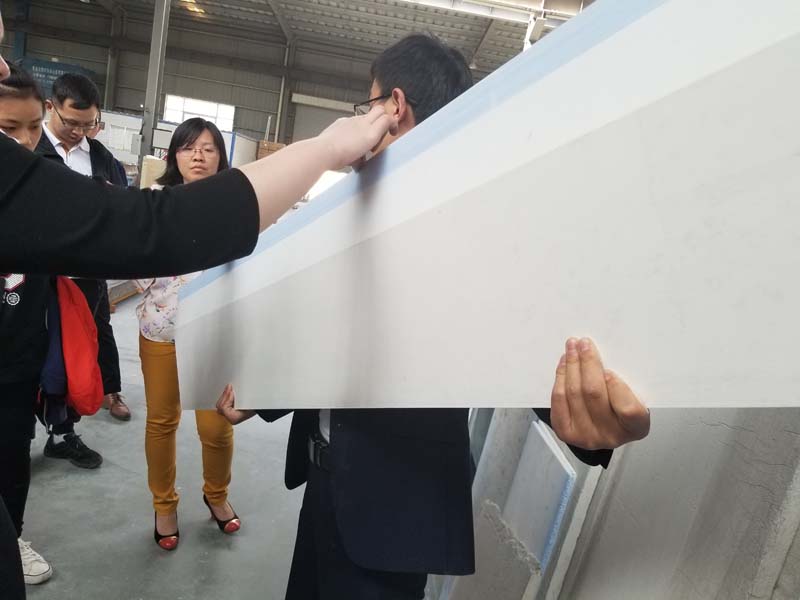

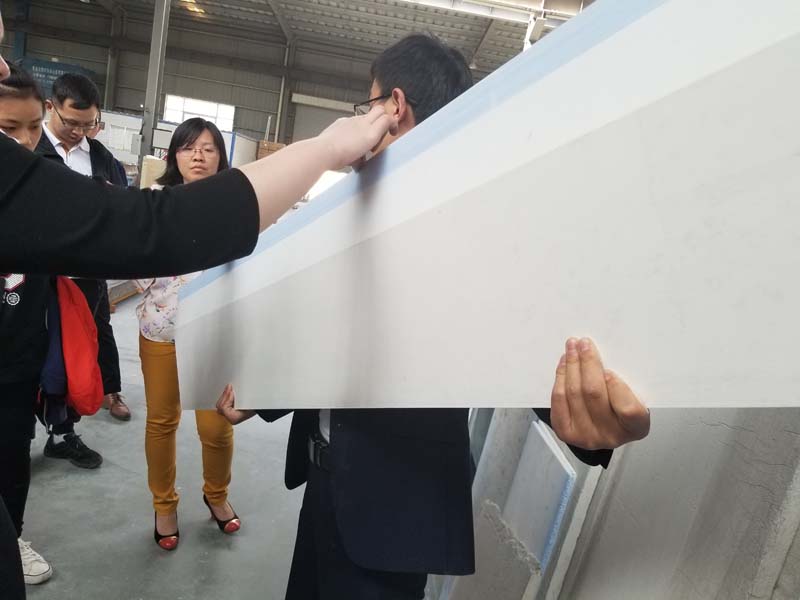

Feeder Caster Tip During the aluminum strip casting process, molten aluminum is fed from the elongated casting tip (or “discharge nozzle”) into the nip between two counter-rotating water-cooled rolls.

The molten aluminum is cooled when it comes into contact with the rolls and cools as it passes between the rolls, thereby forming a wide cast metal strip of uniform thickness.

As long as the liquid metal is supplied to the casting machine, the casting process can proceed continuously.

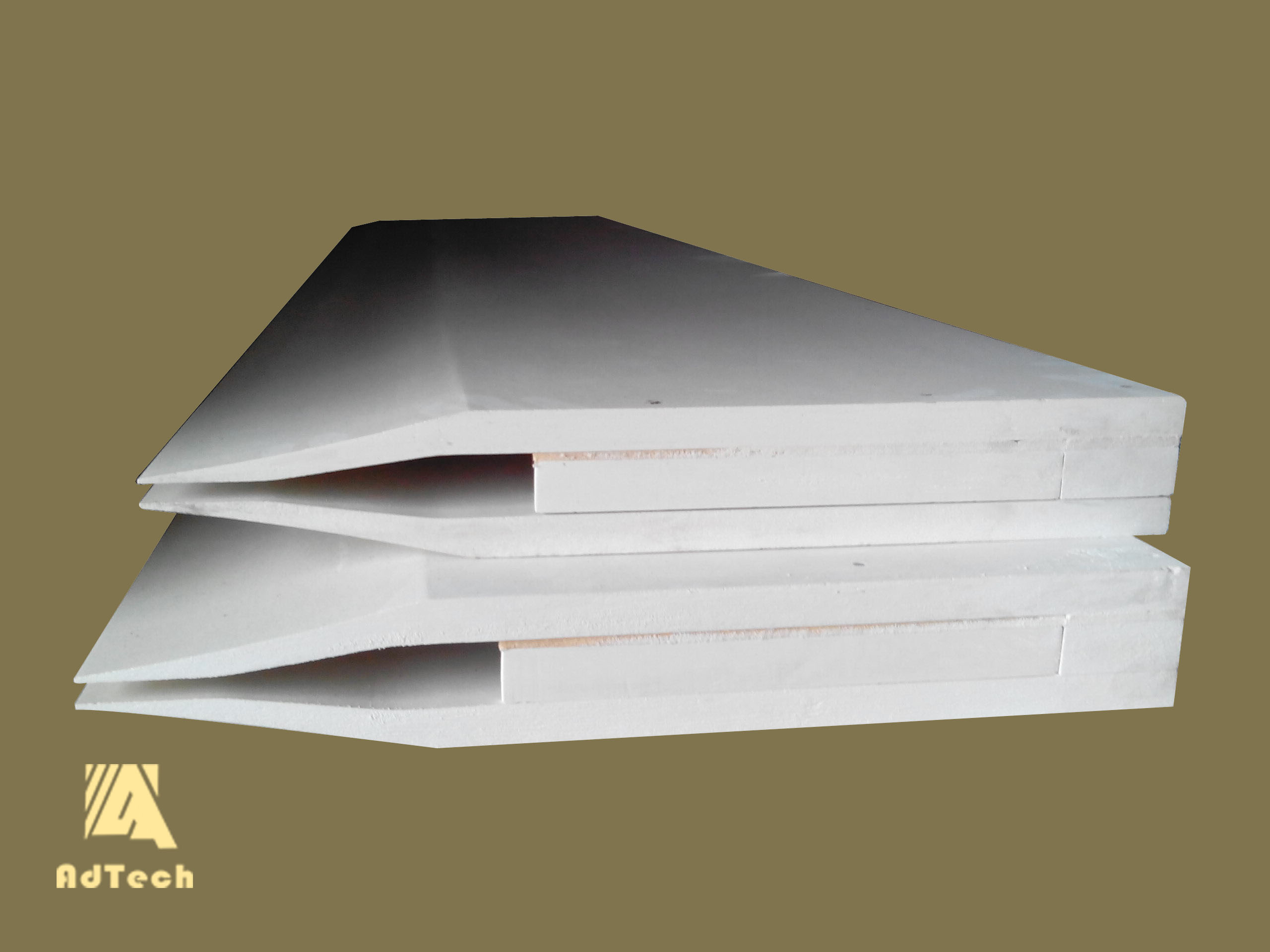

The tip of the Feeder Caster Tip is usually made of a low-density ceramic material that can withstand the wear and thermal shock associated with contact with liquid aluminum, such as a ceramic fiber board formed into the necessary shape.

Because of the low density of these materials, their thermal conductivity is very low (usually less than 0.18 W/mK), and can provide a certain degree of thermal insulation for the liquid aluminum in the Caster Tip.

However, after a period of production, they may be subject to chemical attack and wear. This can lead to the formation of various impurities within the tip structure, and eventually lead to premature stop of the casting movement.

Egypt aluminium introduce that Feeder Caster Tip usually produces the following erosion and wear

1.Castertip blocking

When a blockage occurs in the Castertip cavity, the metal is restricted from flowing out of the entire width of the Castertip opening, causing elongated pore defects on the surface of the cast-rolled strip.

Pores may be small holes, which can be observed with the naked eye.

Sometimes, the voids are inside the strip, and clear oxide streaks can be seen on the surface of the strip.

The correction method is to increase the metal temperature. You can also stop the rotation of the roller for a short time, let the metal solidify around the obstruction, and pull it out when restarting.

In some cases, a blocked Castertip requires replacement of the nozzle plate.

Good refining measures are an effective way to prevent Castertip blockage.

2. Castertip scars

Metal solidification may occur inside the mouth cavity or at the opening of the Castertip.

The metal solidifies in the mouth cavity, which is manifested as a reduction in the width of the strip or a hole in the strip.

The reason for this defect may be the leakage of metal from the Castertip or the low temperature of the metal in the nozzle plate.

The correction methods are:

·If the leakage is serious, replace the casting nozzle plate

·Increase the temperature of molten aluminum in the front box

·Increase the casting speed

3. Fine ripples

This defect is manifested by some horizontally visible light and dark stripes on the surface of the cast-rolled strip. The symptoms of this defect are:

·The strip has horizontal dark stripes

·Rough edges

·The main motor current value decreases

The reasons for this defect are:

·The metal level is too high, and the metal in the Castertip will vibrate due to the excessive metal pressure, which will cause fine ripples on the plate surface.

·The casting speed is low

·Metal temperature is too high

Correction method: reduce the liquid level of the front tank, lower the temperature of the aluminum liquid in the front tank, and increase the Castertip speed to minimize the defect.

Egypt aluminium is introducing the sales@adtechamm.com mailbox of the caster tip manufacturer to the casting factories in Egypt and the Middle East.

Ideally, the heat distribution of the liquid metal leaving the Castertip is as uniform as possible along the length of the caster tip.

The width of the castertip can be between 0.3 m and 2.5 m.

The molten aluminum leaving the Castertip is usually at the hottest state in the center area, and is insulated at the two outer ends of the tip.

The cooler areas are usually located to the left and right of the center area, between the center area and the end area of the caster tip.

These temperature differences will affect the uniformity of the casting process and the quality of the cast metal strip.

Sorry, the comment form is closed at this time.