Launder Dam

About This Project

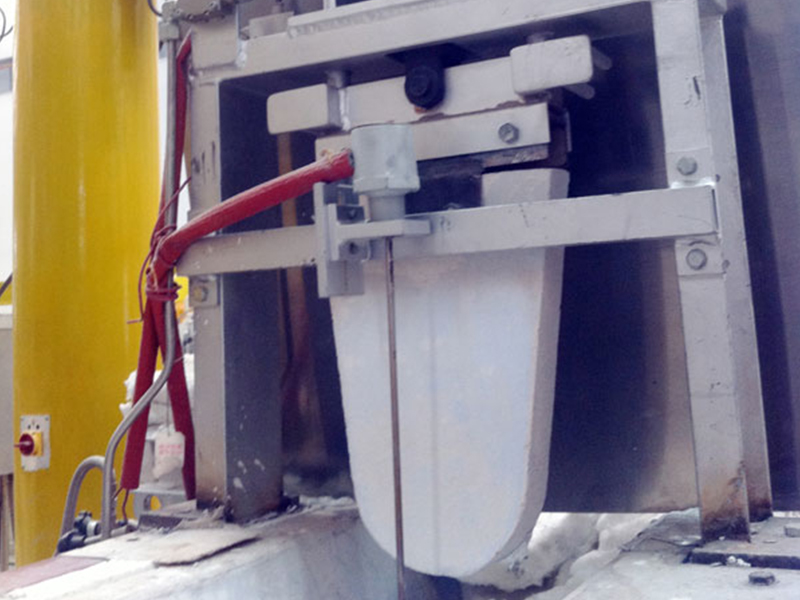

Launder Dam

Launder dam manufacturer which is specialized in the development of new material and production of high-performance insulation sealing. Since 2012, our company has started to R&D launder dam, overall launder, degassing unit and plate filtration unit. Supply integration services in high-precision aluminum alloy casting. Got good reputation in market.

The launder dam is using matched with launder. It is made of new high-silicon melting material or N17 material. It is used for flow control of molten aluminum. And it is corrosion resistance, non-polluting to molten aluminum. Can meet the high value-added, high-tech performance aluminum casting requirement.

Casthing-RAL& Casthing-RC

Assembles:

- Dam Liner

- Metal Accesorries

- Manual or Pneumatic Device

Usage:

The launder dam is applied to dam and release molten aluminum in launder. Formed by different density material. It has the advantages of erosion resistance, impact resistance, good thermal shock resistance and smooth surface, etc. It will has good using performance for matching with our BN coating. Can prolong working life to 30-90 days. (Attached effect picture of painting BN coating)

Advantages:

- The material is made of high-silicon melting material or N17 material. The density: 0.8-2.0 g. cm3Pneumatic, electric and manual dam could be produced as the customer’s requirements. It is better for damming and releasing molten aluminum in launder.

- Erosion resistance, impact resistance, good thermal shock resistance and smoother surface, non-polluting to molten aluminum.3. Operate flexibly, can install the metal clamping device to prolong the working life, save energy and reduce consumption.

Operation Case:

Specification:

| Item | Lining | Manual locking dam | Pneumatic or electric dam | Manual lifting dam |

| Standard | Design / As Drawing | Design / As Drawing | Design / As Drawing | Design / As Drawing |

Packing:

Instructions:

- Install the launder dam to comply with launder as drawing, keep the launder and dam clean, avoid breakage and gap.

- Check all the seals around the dam are sealed properly, it is best to use ceramic fiber paper or ceramic fiber blanket sealing edge to make flow control perfectly.

- Adjust the pneumatic or electric controller well to achieve precise control.