Spacers & Strips

About This Project

AdTech specialized in the production of spacers & strips since 2012, got good reputation in domestic and overseas. It is applied to casting micron sized aluminum foil, PS plate casting, packaging materials, etc.

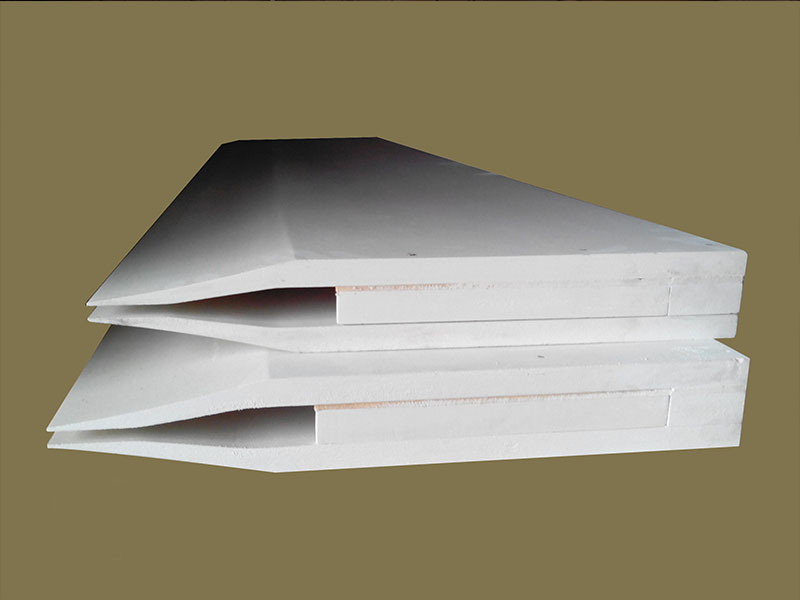

Roll-SS

Assembles for spacers & strips

- Caster tips

- Spacers

- Ears

- Strips

Usage:

spacers & strips are used to assemble caster tips for dimensions, crystallization, molten aluminum flow and temperature control during foil casting. It is made of high purity fiber material, to use with BN is recommended.

Advantages:

- Made of high purity fiber material, precision size, proper density & inflexibility.

- Nano-paint on key parts, layer stout, good erosion resistance.

- Can meet molten aluminum mechanics requirements.

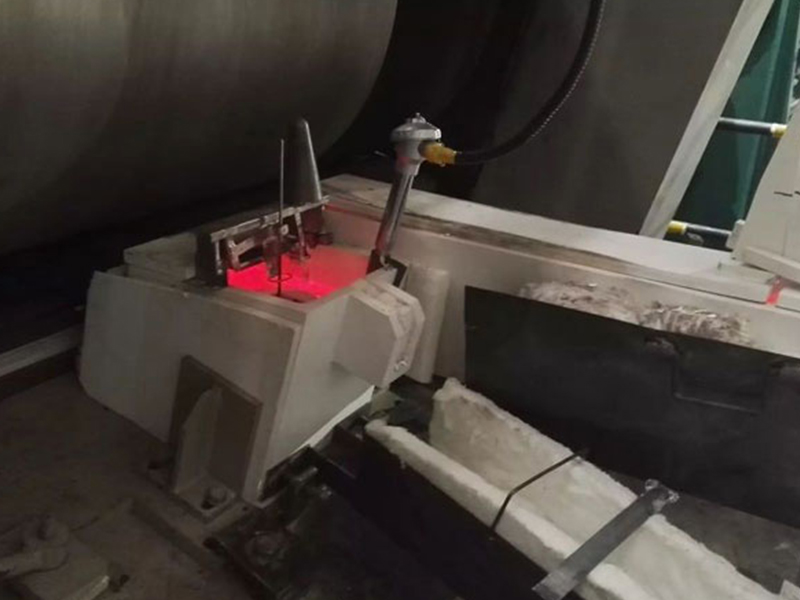

CNC Process

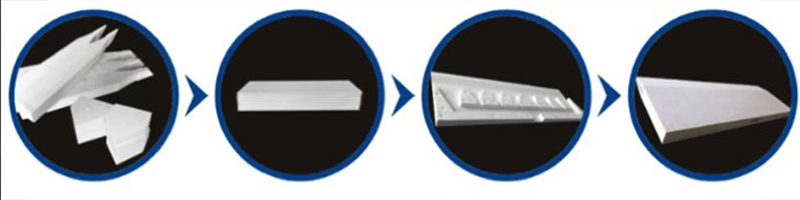

The comparison before and after use Spacers & Strips:

Before

Dimensions (mm):

| Item | Size | Width | Customers’ Requirement |

| Value | 20-500 | 8-30 | Drawing Required |

Instructions:

- Cut and assemble according to drawing, make sure the board is intact.

- Heat the caster tip 2 hours to target temperature, keep the Roll-PH at 260℃ for 5 hours to remove crystal water,cool down to ordinary temperature and ensure proper assembling with 2 hours.

Assembly Process

Foil Molding Process

Package: 50 -100Pcs/wooden case

Storage:

Stored in ventilated and dry environment, moisture proof, do not lay anything on.

Warranty:

7 or more days (For casting molten aluminum 1,000MT)