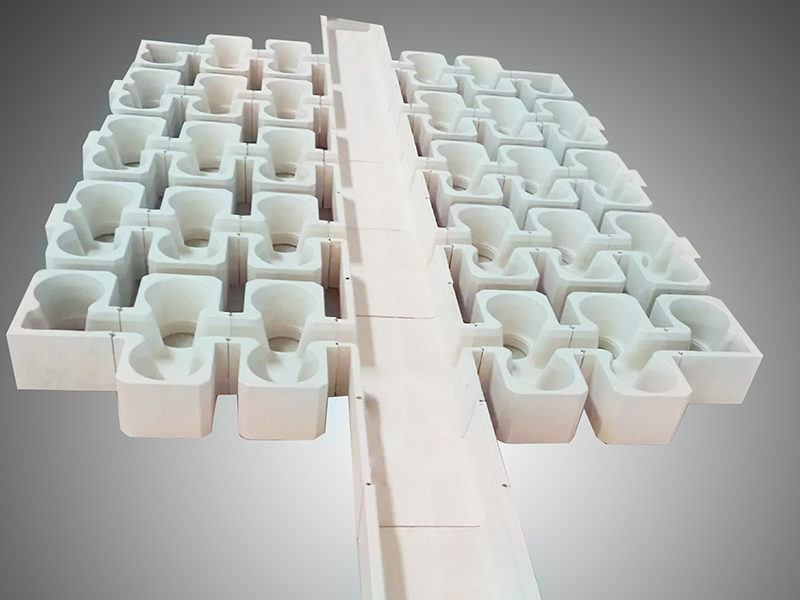

Sprue Bush

About This Project

AdTech Metallurgical Material Co,.Ltd. is a manufacturer specialized in the development of new materials, production of casting sprue bush to transit molten aluminum. AdTech has devoted to research and development control flow series products used to control the flow velocity of molten aluminum since 2012, such as: casting sprue bush, distribution plate, transition plate, hat plate, graphite ring, distribution launder and other products. These products always use cooperatively for precision molten aluminum casting. Especially match with wagstaff air slip casting unit. Our control flow series products have been widely approved by the market.

AdTech’s thimble is made of two kind of materials: high silicon melting 140 materials and Al-Si materials. It is the best choice for hot-top aluminum casting with high corrosion resistance, high geometric precision, smooth surface, long service life, low maintenance cost and non-pollution to molten aluminum. Can meet the high value-added, high-tech performance aluminum casting requirement.

Mlod-TRH

AdTech’s main parts of Hot-top casting :

- Casting sprue bush

- Transition plate

- Distribution Plate

- Graphite Ring

- Distribution launder

Advantages:

- High hardness, high erosion resistance, high geometric precision, low maintenance cost, smooth surface;

- Non-peeling off, non-pollution to molten aluminum and it is obviously improve quality of aluminum alloy;

- Good thermal shock resistance, reduce the pollution to molten aluminum for corrosion resistance casting;

- It’s excellent to use with BN, can be used for 450-800 times casting, energy saving.

The comparison before and after using sprue bush and distribution plate:

Specification (Based on the alloy diameter):

| 3in | 3.5in | 4.5in | 5in | 5.5in | 6in | 6.5in | 7in |

| 8in | 9in | 10in | 12in | 14in | 16in | 18in | 20in |

Technical parameter for high silicon 140 sprue bush :

| Item | Denisity (g/cm3) |

Compression Strength (Mpa) |

Thermal Expansivity (X*10-6/℃) |

Max Working Temperature (℃) |

| Index | 1.4-1.5 | 15-16 | 4-4.5 | >1000 |

Packaging:

Instructions of hot-top casting series:

- Choose the right size parts to install in hot-top casting equipment.

- The distribution plate, sprue bush, transition plate, distribution launder and graphite ring install above the platform, and sprue bush, transition plate, graphite ring below. Ensuring the product smooth, clean, undamaged and seamless and it is better to sealed around the side and bottom with ceramic fiber blanket or ceramic fiber paper for thermal insulation.

- Preheat the hot top casting platform uniformly to 260℃-350℃ after installation completed. If electric heating is not available, heat it by flame is recommended to get rid of adsorbed crystal water. Direct fire on the lining body is prohibited.