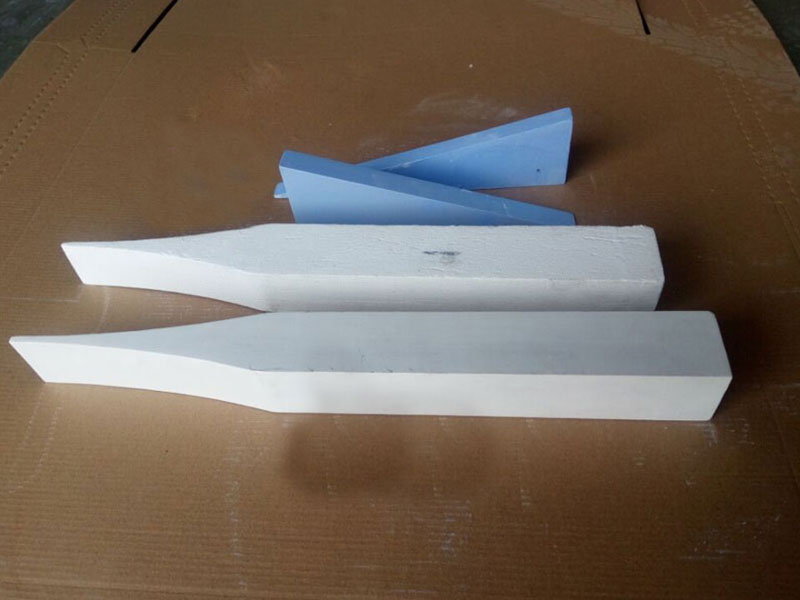

Ears

About This Project

AdTech specialized in production of soft/hard ears, spacers & strips to match caster tips since 2012 and got good reputation in domestic and overseas. The ears are mainly used for Micron sized aluminum foil, PS plate casting.

Roll-ESP&Roll-EHF

Assembles for ears

- Caster tips

- Spacers

- Ears

- Strips

Usage:

Soft/Hard ears are used to assemble caster tips for dimensions, crystallization, molten aluminum flow and temperature control during foil casting. Soft ear is made of high-alumina fiber board and hard ear is made of high purity fiber material. They can maintain the stability of internal layer for casting roll.

Advantages:

- CNC controlled with precision size, proper density & inflexibility.

- Smooth surface with good erosion resistance.

- The strength of soft ear is moderate which solved the cracking from the layer, increased service life, can adjust the cater tips and fixture best.

- The symmetrical runner design can meet molten aluminum mechanics requirements.

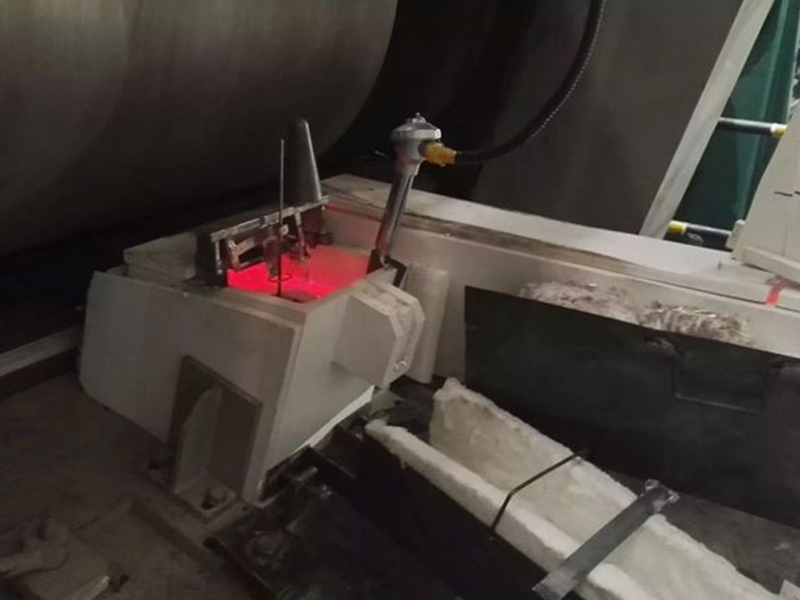

CNC Process

Dimensions (mm):

| Item | Size | Width | Customers’ Requirement |

| Value | 20-600 | 20-60 | Drawing Required |

Instructions:

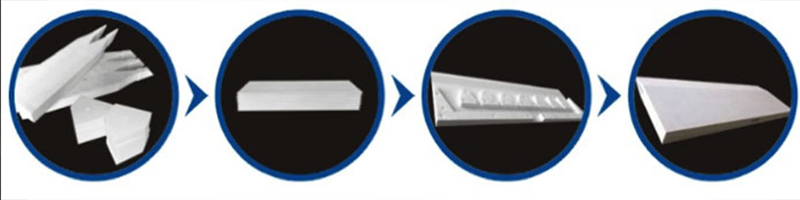

- Cut and assemble according to drawing, make sure the board is intact.

- Heat the caster tip 2 hours to target temperature, keep the Roll-PH at 260℃ for 5 hours to remove crystal water,cool down to ordinary temperature and ensure proper assembling with 2 hours.

Assembly Process

Foil Molding Process

Package: 50 -100Pcs/wooden case

Storage:

Stored in ventilated and dry environment, moisture proof, do not lay anything on.

Warranty:

15 or more days (For casting molten aluminum 2,000MT)