08 5月 Aluminum Silicate Ceramic Caster Tip,Casting Tips And Nozzle

Aluminum Silicate Ceramic Caster Tip,Casting Tips And Nozzle

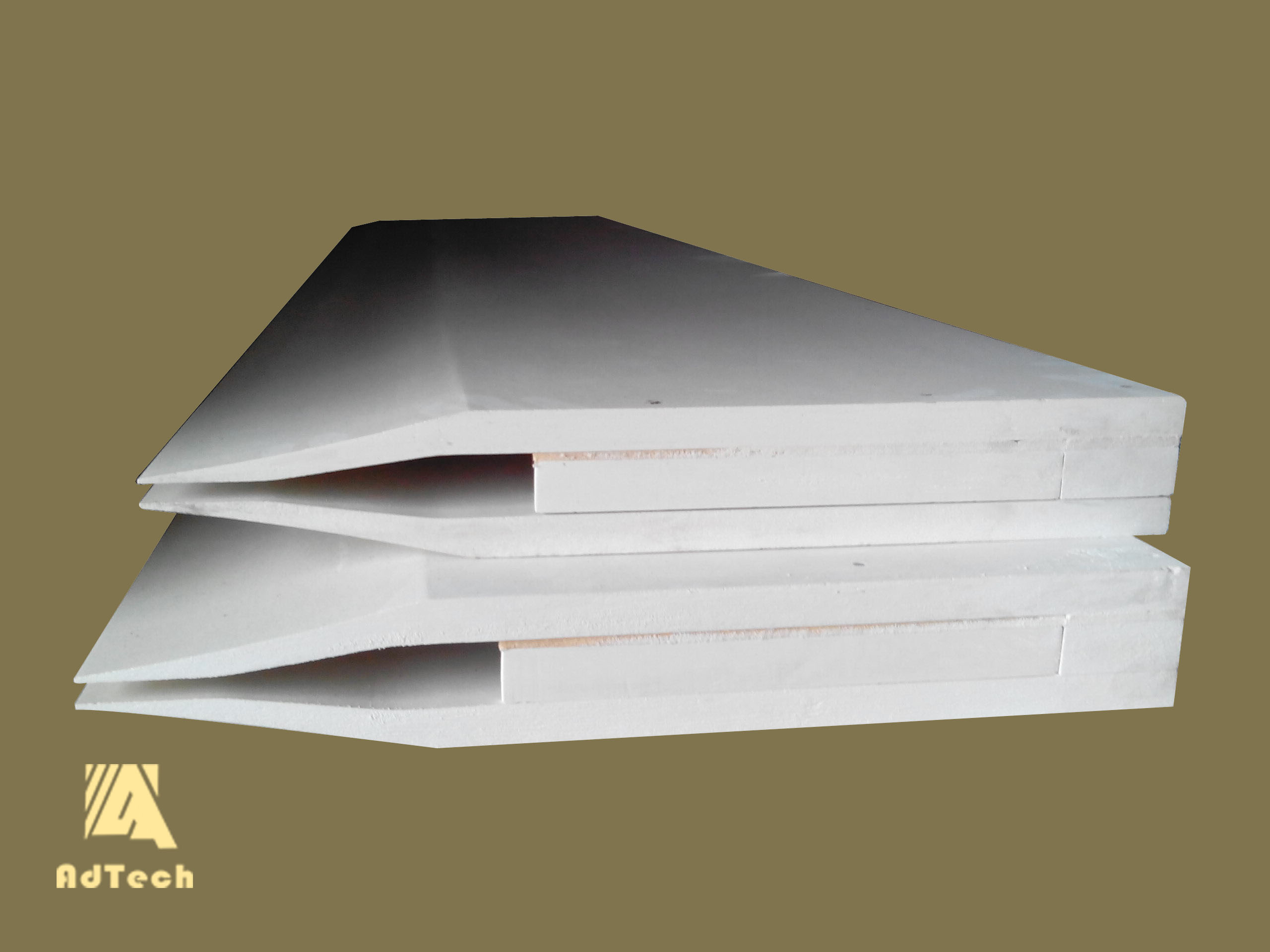

Caster tip has a uniform distribution of internal short fiber structure, moderate density, good heat preservation, precise size, high oxidation resistance, no delamination, no deformation, low deformation, effective protection of cast-rolled sheet surface quality, and nitriding. Boron coatings work better.

Its special process can effectively prevent the aluminum liquid from eroding the Caster tip to avoid carbonization; the fracture structure is a fine and uniform layered fiber structure to prevent the existence of flake-like floc structure; the working surface coating is even and smooth, preventing granules The occurrence of cracks and coating shedding provides protection for high quality cast sheets.

Caster tip Product Benefits

1. Caster Tip adopts nano-scale fiber composite material for integral molding, processed by high-precision equipment, precise size control and suitable density and stiffness.

2. The key parts are strengthened by nano-coating, sealing surface, no delamination and non-stick performance, and enhanced anti-aluminum liquid erosion performance.

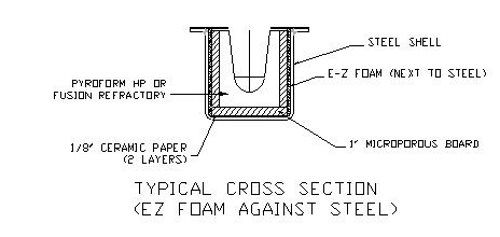

3. The rational structure of the symmetric flow channel is designed in the internal structure to meet the fluid mechanics requirements of aluminum liquid.

4, better heat preservation, effective control of cast iron zone parameters constant temperature, is the best choice for casting high-quality aluminum foil blanks.

5, low deformation, easy to adjust the gap between the nozzle roll, improve the surface quality of the aluminum foil blank, effectively improve the white and dark lines.

According to the influence of casting speed, casting cavity exit height dimension and total cavity length, Caster tip compares numerical simulation results of variable density and constant density melt, revealing the flow field and temperature field of high temperature shallow aluminum melt. Distribution.

It is concluded that the numerical simulation should adopt the three-dimensional model, and the two-dimensional model is unreasonable and does not conform to the reality.

The melt flow velocity and outlet temperature increase with the increase of casting speed. Changing the inlet velocity distribution can improve the uniformity of temperature and velocity of the cavity melt outlet.

Changing the number of shunt blocks can improve the exit velocity distribution and temperature distribution uniformity.

Properly reducing the cavity opening degree can obtain a more uniform exit velocity distribution and temperature distribution.

Increasing the cavity length results in a more uniform melt exit velocity distribution and a more uniform temperature distribution.

In the practical application of engineering, the apparent density is the rationality of constant density. The numerical simulation results and analysis conclusions provide an important basis for continuous casting and rolling, especially for the best matching parameters of rapid casting and rolling.

On the basis of the simulation calculation of the convection field and the temperature field, the high aluminum casting nozzle cancels the fixed diversion block of the existing nozzle cavity, and sets a row of positionally controllable Caster Tip Ear in the front box close to the casting nozzle.

.

Caster tip realizes a flow control device that synergistically regulates the aluminum melt flow field, temperature field, solute (alloy element) concentration field and strip quality, and creates favorable conditions for improving the quality of cast strip. The utility model has the advantages of simple equipment, convenient operation, strong function, safety and reliability, and is suitable for industrial production.

Sorry, the comment form is closed at this time.