21 1月 Castertip

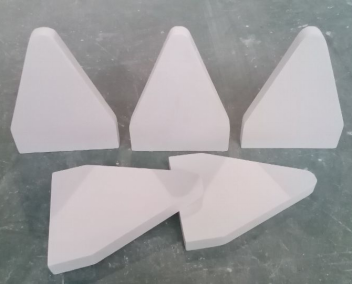

Aluminum Silicate Castertip

Casting tip is engineered for the production of high quality, continuous cast aluminium sheet. These tips are made from ceramic fibers bonded with inorganic binder. They are dimensionally stable, thermal shock resistant, and do not cause outgassing.

Completely assembled Castertip are often preferred by customers due to the precision and convenience. These are custom made and shipped to the customer ready to insert into the caster tip base. Internal designs can be made according to customer specifications.

Aluminum silicate Castertip are the key parts of the continuous aluminum trip casting machine which directly effect the quality of aluminum sheets. The castertips can be divided into many types according to different casting machines.

Aluminum silicate Castertip is compounded by ceramic fiber and some other refractory materials. The opening surface and the coating of the working surface are smooth and it can resistant to the corrosion of the liquid aluminum, guarantee the purity of the aluminum sheet.

Castertips with excellent non-wetting properties, low thermal conductivity, high temperature stabilities, uniform density, smooth surfaces and close tolerance, is superior products for continuous aluminium strip casting.

Castertip Usage:

It is made of nano-grade fiber composite material and used for crystallization and size control of aluminum foil casting. It features fiber uniformly distributed, proper density, good insulation, accurate size, good inoxidizability, layer stout, Non-deformation. Can protect foil surface. To paint BN is recommended.

Castertip Advantages:

Made of nano-grade fiber composite material, precision size, proper density & inflexibility.

Nano-paint, layer stout, good erosion resistance.

Can meet molten aluminum mechanics requirements.

Good insulation, control parameters in foil casting.

Low deformation, improve quality of aluminum foil.

No Comments