25 11月 Casting Tip

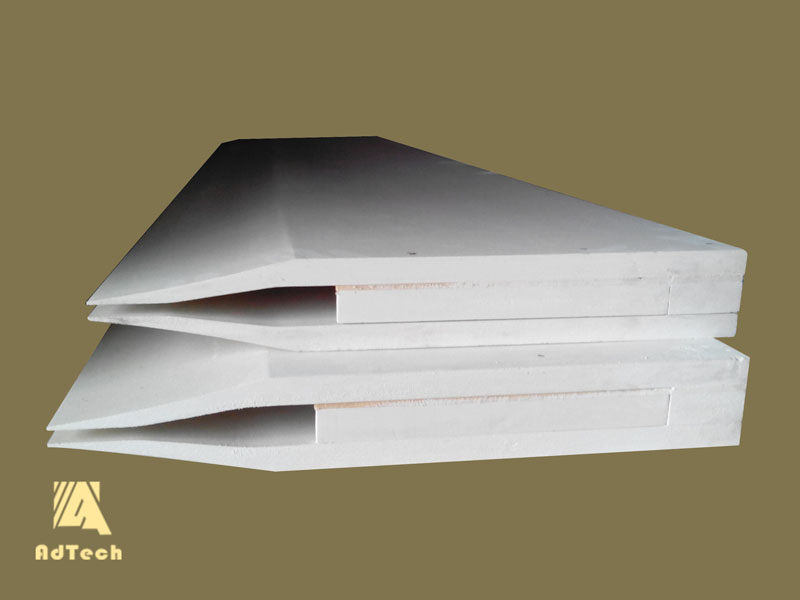

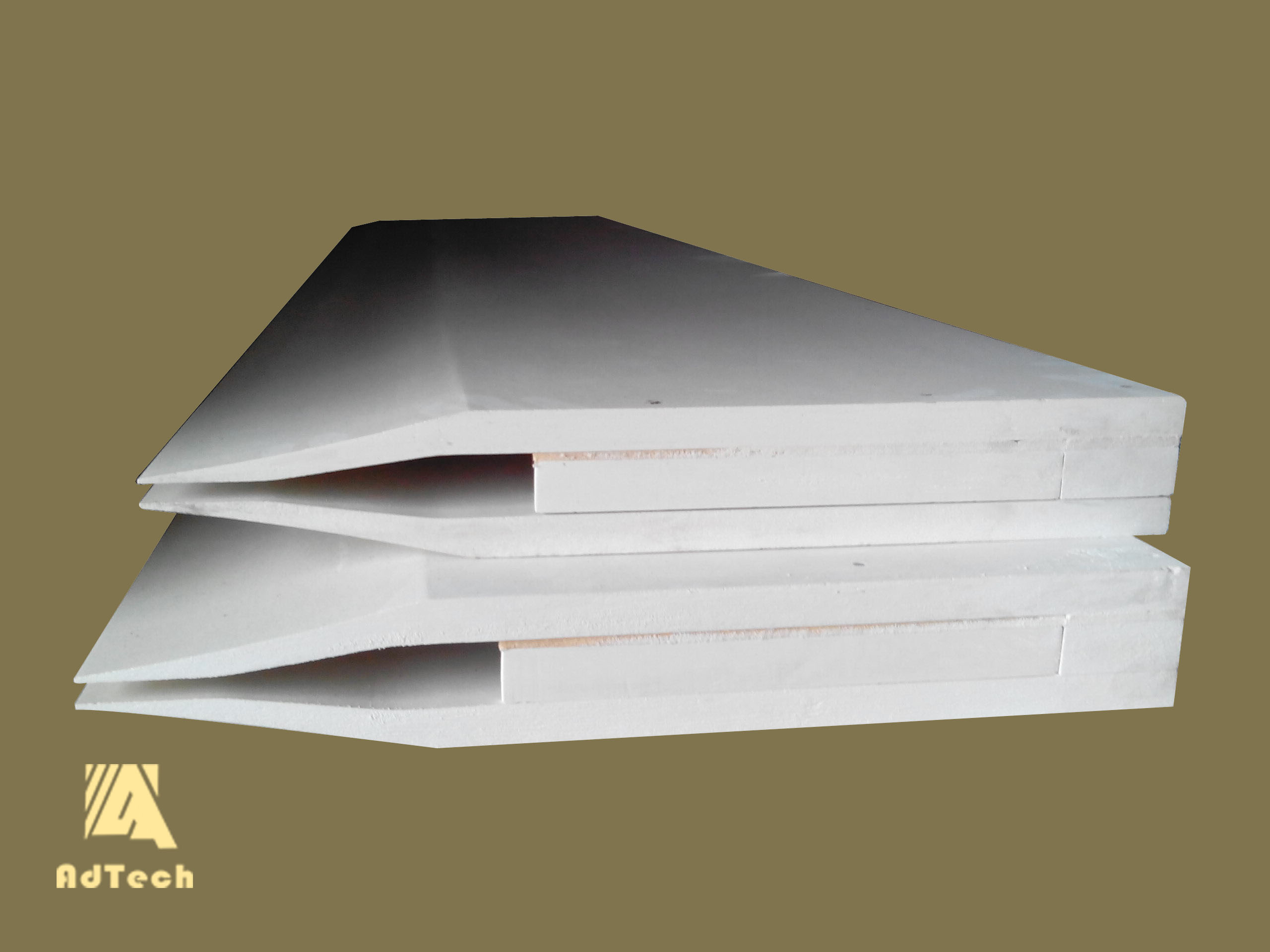

Casting Tip is made from a special, sintered ceramic material by machining, and is used for Continuous twin roll aluminum strip casting. The material has good thermal stability and can penetrate any gas released by the molten metal from the tip of the casting nozzle.

In order to ensure that the aluminum liquid flows at a uniform rate in the transverse direction of the casting cavity and the local cooling rate of the mold surface is consistent, the silicon aluminum fiber material is vacuum formed to manufacture the Casting Tip.

The molten metal begins to solidify between the steel strips, forming a solid surrounding and liquid casting billet moving downstream of the casting mold.

When the Aluminum Strip reaches the end of the mold, usually only about 70% to 80% of the entire cast billet is solidified.

Applications

Continuous twin roll aluminum strip casting

Advantages

Excellent non-wetting properties

Smooth surface

Excellent hermal insulation

Customized products

End dams and baffle boards for continuous casting of aluminum strip.

Launders, distribution boxes, pouring spouts, hot tops

Product Feature

Excellent non-wetting properties

Smooth surface

Excellent hermal insulation

Application / Models

Continuous twin roll aluminum strip casting

If you are interested in our castertips, pls feel free to contact sales@adtechamm.com

Sorry, the comment form is closed at this time.