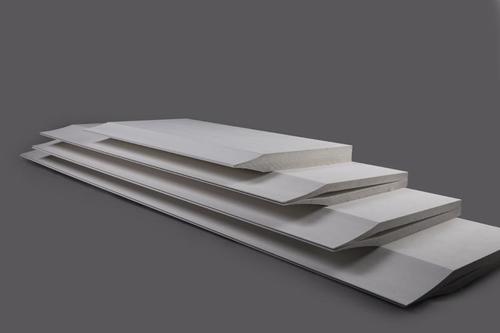

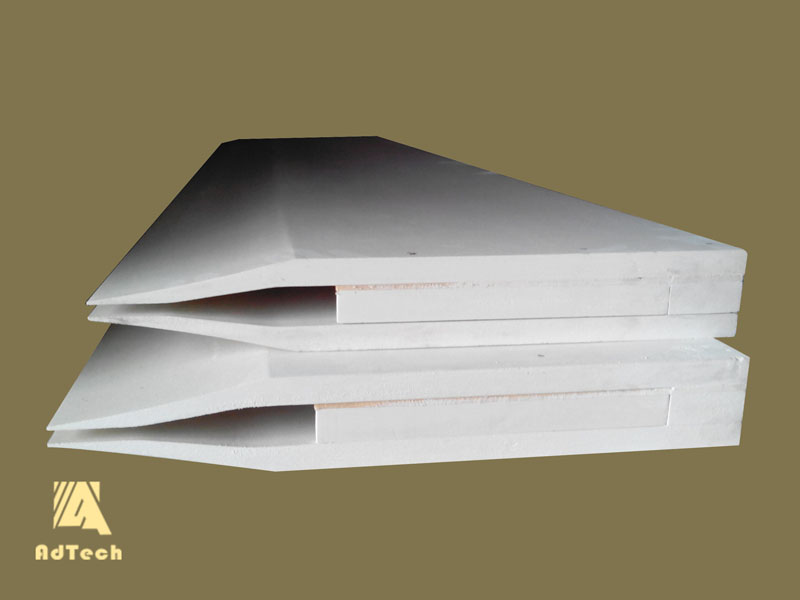

17 1月 Feeder Casting Spile

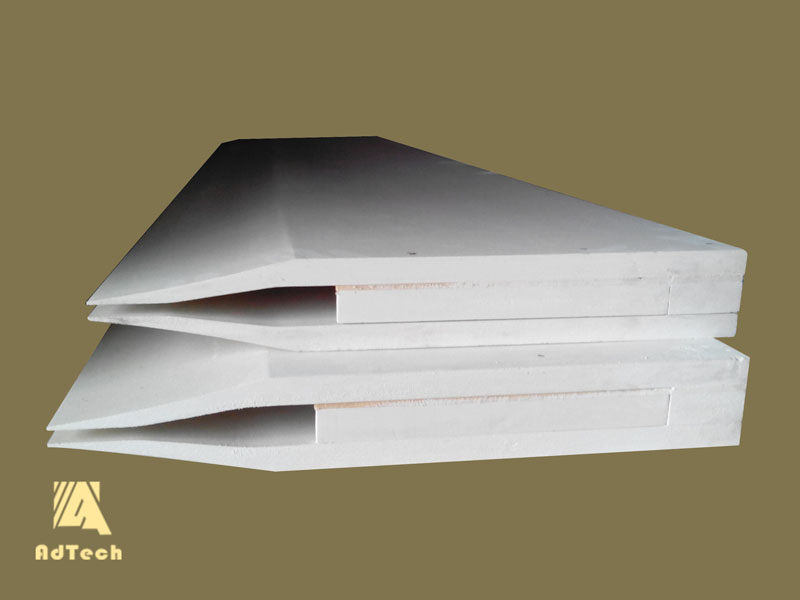

Feeder Casting Spile uses a special process to effectively prevent molten aluminum from eroding Casting Spile and avoid carbonization. The fracture structure is a fine and uniform layered fiber structure to prevent the existence of flocculent structures. The working surface coating is uniform and smooth,...