22 4月 Aluminum Degassing Equipment

Aluminum Degassing Equipment

The aluminum die casting industry requires strict metal quality standards to prevent part failures in critical components of automobiles, aircraft and machinery.

Aluminum Degassing Equipment removes inclusions and alkaline metals from molten aluminum to improve metal quality. Inclusions may cause decreased fluidity, increased porosity, loss of mechanical properties, poor surface quality, tool breakage, lack of pressure tightness, and reduced corrosion resistance.

During the degassing process, an inert gas is pumped into the aluminum melt to remove hydrogen and prevent subsequent voiding in the casting.

In general, gas diffusion through the rotor achieves maximum gas output efficiency.

Aluminum Degassing Equipment helps to remove other impurities such as oxides from the surface of the melt.

Aluminum Degassing Equipment Advantage

Optimize bubble saturation of process gases throughout the melt

Reduce the formation of scum

Pushing the flow of metal in the container

Easy to replace refractory

Improve metal quality

Aluminum Degassing Equipment Benefit

Degassing Equipment has high degassing efficiency

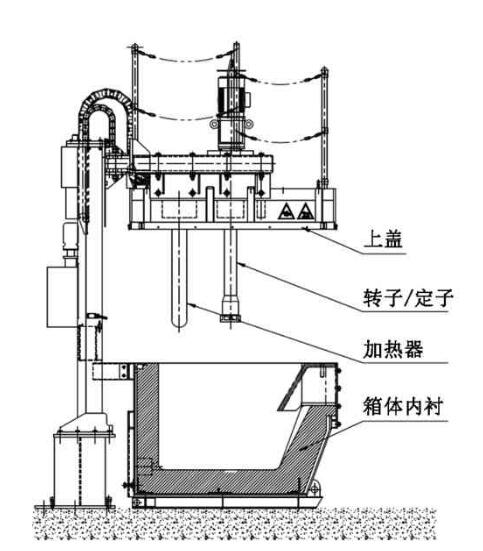

The compact furnace design is adopted, and the rotating nozzle is used for degassing in the degassing box to form convection in the tank, so that small bubbles can be fully diffused in the aluminum liquid. The contact surface of the bubble and the aluminum liquid is increased; at the same time, the sealed design is adopted, the secondary air pollution is prevented from entering the outside air, and the degassing efficiency of the device is improved.

Degassing Equipment Control

The method of degassing the workstation is adopted, the aluminum liquid can maintain the temperature by electric heating in the working gap, the heating system adopts the immersion heating device, the heating efficiency is high, the silicon carbon rod is used for heating the component, the thyristor is controlled by temperature, and the temperature control precision is high. Easy to use.

Aluminum Degassing Equipment is easy to operate

With one-button switching, the design is simple and easy to use, which reduces the complexity of the system and reduces the maintenance cost of the equipment. At the same time, the user’s different requirements for casting quality are considered in the design of the equipment, and the refining gas flow rate and the rotor speed are adjustable.

Aluminum Degassing Equipment is easy to maintain and maintain

Convenient for equipment maintenance and rotor replacement, the rotating nozzle part and the heater part can be lifted separately, and the upper cover can be lifted and horizontally rotated to maximize maintenance and maintenance operations.

Aluminum Degassing Equipment Operational Safety

The equipment has a chain mechanism to avoid injury caused by misuse.

No Comments