19 4月 Degassing Aluminum With Chlorine

Degassing Aluminum With Chlorine

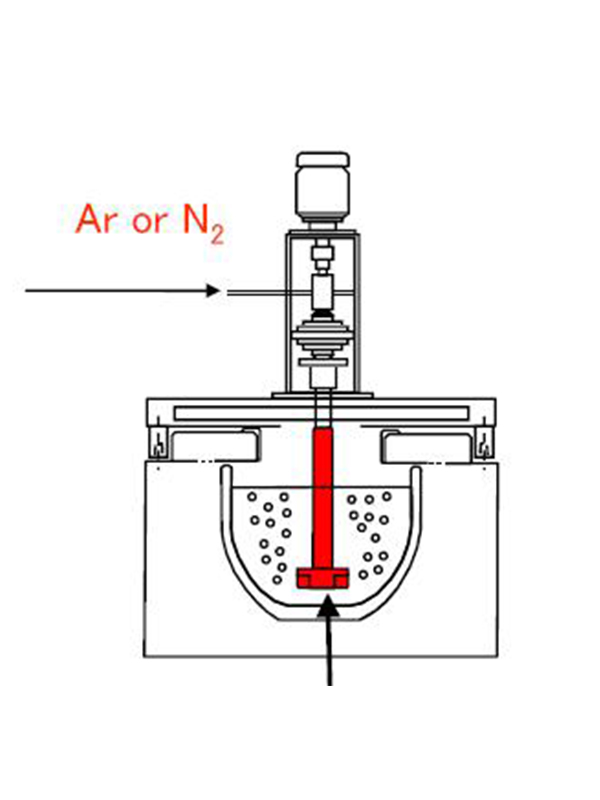

Degassing Aluminum With Chlorine is a major primary aluminum purification process using a gas mixture of chlorine, nitrogen or chlorine.

Degassing Aluminum With Chlorine

Previously, reactive gas chlorine was used as a purifying agent (chlorination method). In the chlorination method, when chlorine gas is introduced into the aluminum liquid, a lot of abnormally small AlCl3 is formed, and the bubbles are sufficiently mixed in the aluminum liquid.

Hydrogen dissolved in the aluminum liquid, as well as some mechanical inclusions, are adsorbed on the AlCl3 bubbles, and are discharged as the AlCl3 bubbles rise to the surface of the aluminum liquid.

When chlorine is introduced, some elements that are more negatively charged than aluminum can be chlorinated, such as calcium, sodium, magnesium, etc., which are separated by chlorine gas to form corresponding chloride.

Therefore, the chlorination method is a very effective primary aluminum purification method. The amount of chlorine gas is 500-700g per ton of aluminum.

However, because oxygen is toxic and relatively expensive, in order to avoid air pollution and reduce the cost of aluminum ingot production, the chlorination process has been gradually abolished into an inert gas-nitrogen purification method in the modern aluminum industry.

Degassing Aluminum With Nitrogen

Alumina balls (418 mm) were used as the filter medium. N2 is directly introduced into the aluminum liquid.

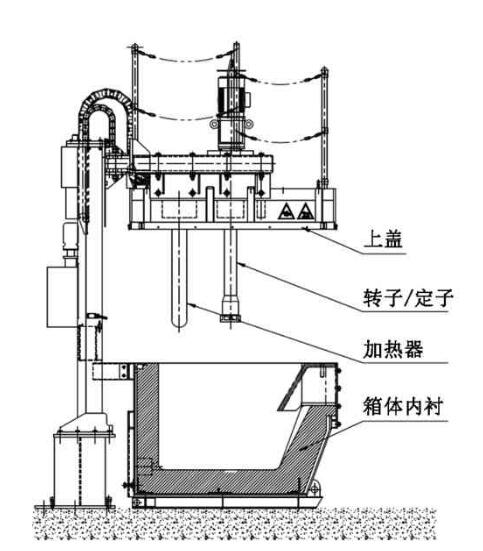

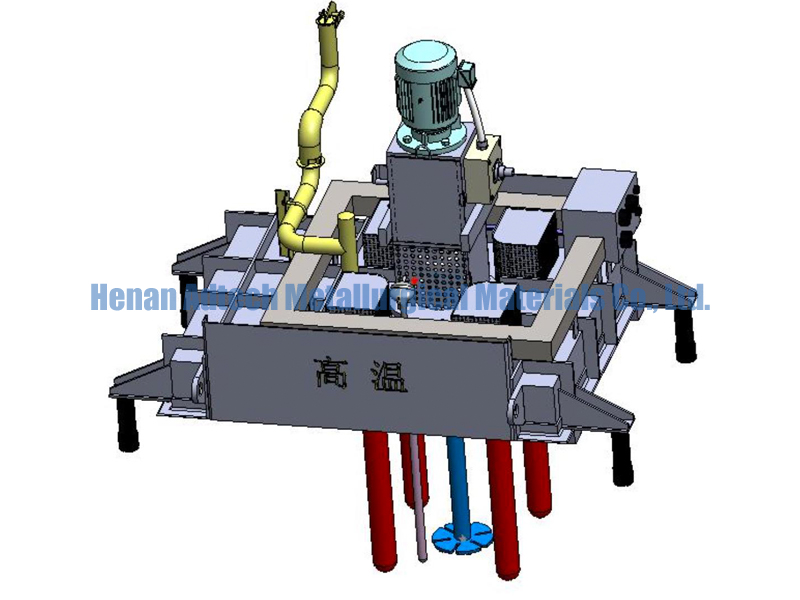

The aluminum liquid is continuously fed into the purification furnace, passed through the alumina ball filtration layer, and is flushed with nitrogen, so that the non-metallic inclusions and dissolved hydrogen in the aluminum liquid are removed, and then continuously discharged, thereby uniformly distributing the fine nitrogen bubbles. It acts as a purifying agent in the treated aluminum liquid.

Nitrogen has no pollution to the atmosphere, and the purification treatment is large. It can process 200-600kg of aluminum liquid per minute, and the amount of aluminum loss caused by the purification process is relatively reduced, so it is widely used now.

But it does not remove calcium, sodium, and magnesium from aluminum in the same way as chlorine.

Degassing Aluminum With Chlorine and Nitrogen

A mixture of chlorine and nitrogen is used to purify the aluminum liquid, which acts to remove hydrogen and separate oxides on the one hand, and to remove certain metal impurities (such as magnesium) from aluminum on the other hand. The usual composition is 90% nitrogen and 10% chlorine.

There are also 10% chlorine + 10% carbon dioxide 80% nitrogen. This effect is better, carbon dioxide can make chlorine and nitrogen diffuse well, which can shorten the operation time.

ADTECH keeps focusing on the manufacture of the metallurgical material.

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

1.Ceramic Foam Filter

2.Degassing Unit

3.Filter Box

4.Hot-top casting series

5.Roll casting nozzle

6.Flux series

7.Other Metallurgical Material

SALES@ADTECHAMM.COM

Mahmoud -Motevaze

Posted at 21:20h, 10 9月Greetings. Dear sir :MD. We are an engineering and consulting company in Iran ,we have an enquirer for a degassing high tech machine for Al Melt degassing Please send ur quotation with all technical. Specification to m.motevaze@dfk.co.ir and a copy to my personal email:mahmotevaze@yahoo.com. And a copy to my what’s app +98-9125207496. Best Regards