22 4月 Degassing Aluminum With Nitrogen

Degassing Aluminum With Nitrogen

Aluminum and aluminum alloy melts contain a large amount of hydrogen, metal and non-metallic inclusions.

If the above harmful substances cannot be removed in time before casting, casting defects such as pores, inclusions and looseness will be formed inside and on the casting, which seriously affects the physical, chemical, mechanical and deep processing properties of the castings, resulting in a large amount of waste products.

No corrosion to the ladle or the lining of the crucible. Since argon or nitrogen is used as the refining medium, there is no pollution to the environment.

Degassing Aluminum With Nitrogen

1. The fixed aluminum liquid mixing and refining degasser is suitable for refining and degassing and purifying the solution in the chute of aluminum and waste aluminum alloy smelting, and can also be placed on the lid of the simmering furnace for refining and degassing.

2. Degassing Aluminum With Nitrogen (hydrogen removal) equipment is suitable for aluminum casting, using argon or nitrogen as a refining medium.

An off-site refining facility that removes hydrogen, metals, and non-metallic inclusions from an aluminum melt.

The graphite rotor of the Degassing Aluminum With Nitrogen is placed in the aluminum melt, and the quantitative refined gas is introduced into the melt by a high-speed rotating graphite rotor.

After relatively high-speed shearing of the graphite rotor and the aluminum liquid, fine bubbles are generated and uniformly dispersed in the aluminum melt.

Since the partial pressure of hydrogen in the bubble is zero, the partial pressure of hydrogen in the aluminum melt is high, which causes the hydrogen in the aluminum liquid to gradually diffuse into the bubble.

The metal and non-metallic inclusions in the aluminum liquid are adsorbed on the surface of the bubble, and the bubbles and the carried inclusions float up, thereby achieving the purpose of removing hydrogen and inclusions in the aluminum liquid.

3. The spray-type refining degasser is based on the mobile aluminum liquid refining degasser and adds an automatic powder feeding mechanism.

When nitrogen or argon is introduced while rotating, the parameters such as powder feeding amount, powder feeding time, and rotating rotor speed can be adjusted, and the device is a new type of aluminum liquid refining degassing and slag removal simultaneously.

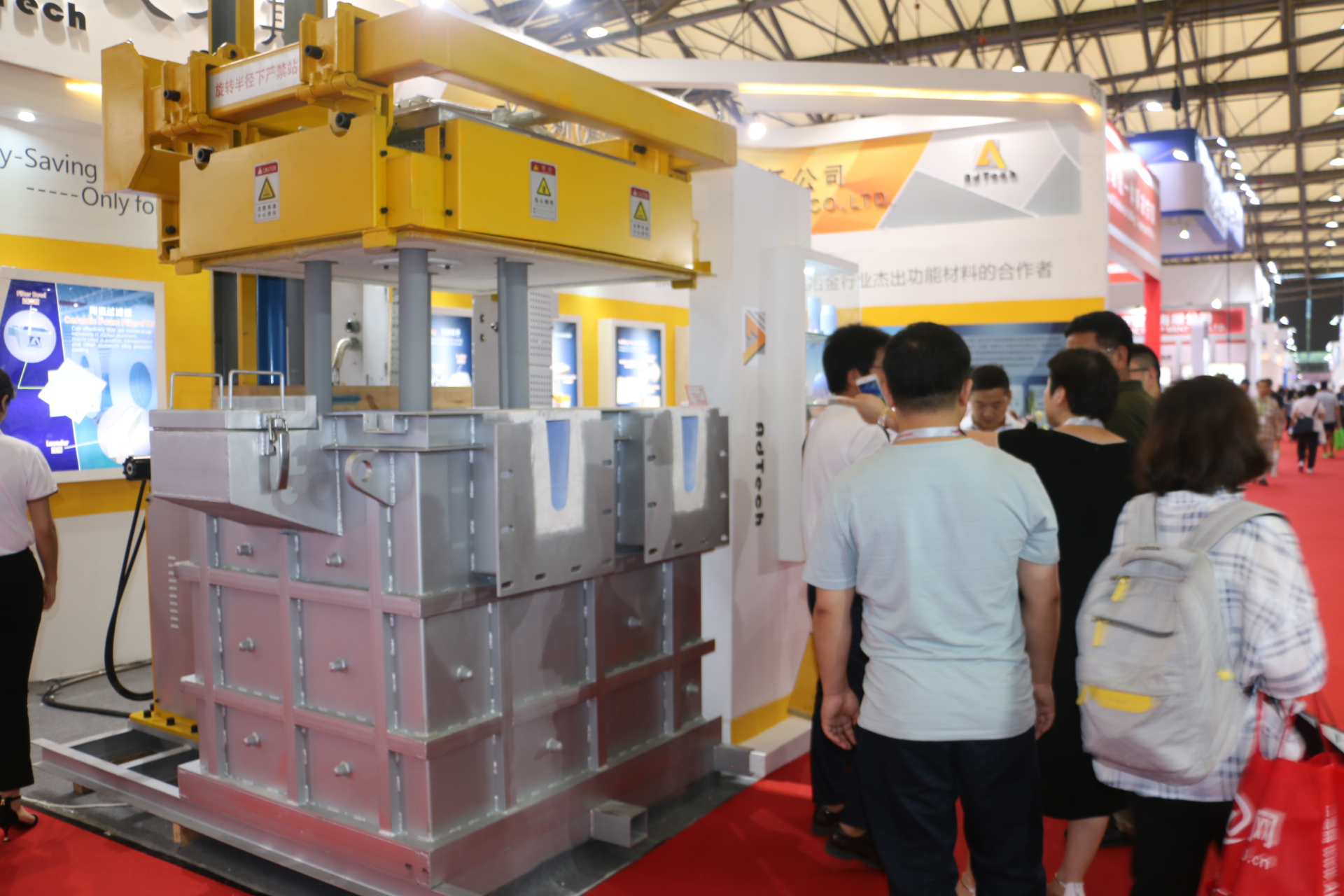

4. Lifting type refining degasser, aluminum alloy solution degassing unit, using the driving lifting deaerator to be placed on the crucible furnace.

After the graphite rod is aligned with the center of the aluminum liquid, the stirring and nitrogen switch is turned on, and nitrogen gas is rotated while rotating, that is, the hydrogen in the aluminum liquid is removed, and the slag is stirred to the surface of the aluminum liquid.

Sorry, the comment form is closed at this time.