14 5月 Aluminium Hydrogen Degassing Equipment

Aluminium Hydrogen Degassing Equipment Operation

The hydrogen content of aluminum melt has a decisive influence on the properties of aluminum and aluminum alloys. Therefore, Hydrogen Degassing has become one of the necessary means to control the quality of the aluminum processing industry. The Hydrogen Degassing method and Hydrogen Aluminium Hydrogen Degassing Equipment for aluminum melts have developed quite rapidly, and there are many Hydrogen Degassing devices developed.

At present, the most complete, reliable and repeatable aluminum melt liquid Hydrogen Degassing technology is Adtech Hydrogen Degassing Unit.

The liquid aluminum alloy purification treatment process is the main means to improve the comprehensive performance of aluminum alloy.

In the purification treatment process, the purification gas and the solvent are mixed, and the method of purifying the aluminum melt by the rotation of the graphite rotor on the Aluminium Hydrogen Degassing Equipment is the most advanced treatment method in the world.

Aluminium Hydrogen Degassing Equipment works on the principle that a rotating rotor breaks up nitrogen (or argon) blown into the aluminum melt into a large amount of dispersed bubbles and disperses it in the molten metal.

The bubble in the melt relies on the gas partial pressure difference and the surface adsorption principle, absorbs the hydrogen in the melt, adsorbs the oxidized slag, and is taken out of the melt surface as the bubble rises, so that the melt is purified.

Due to the small dispersion of the bubbles, it is uniformly mixed with the rotating melt, and then rotates in a spiral shape and slowly floats. The contact time with the melt is long, and the air flow generated by the continuous straight rise does not form, thereby removing harmful hydrogen in the aluminum melt, which is remarkable. Improve the purification effect.

Affects the removal rate of hydrogen and inclusions in the aluminum solution of Aluminium Hydrogen Degassing Equipment.

(1) Metal flow or volume

(2) Inert gas flow rate

(3) Diffusion of inert gas

(4) Contact of inert gas and impurities.

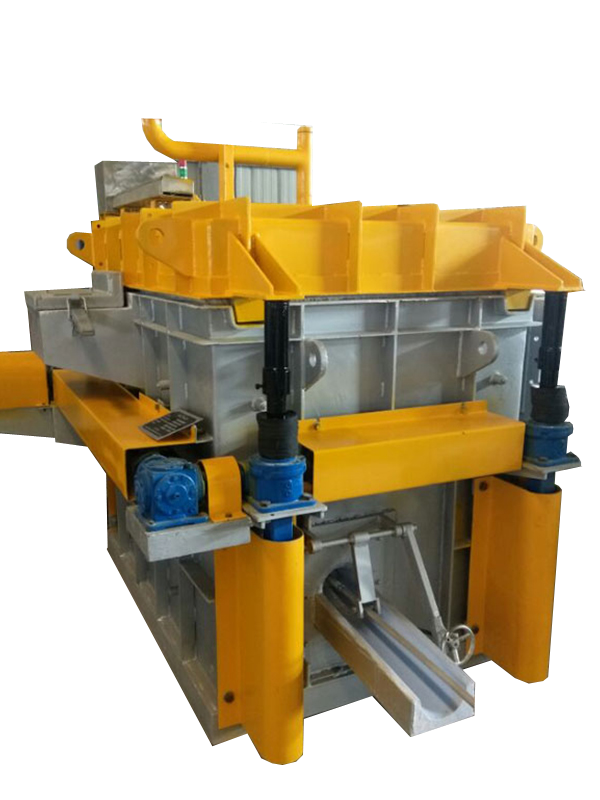

The double rotor Aluminium Hydrogen Degassing Equipment can realize continuous degassing of the aluminum melt, and the aluminum melt processing amount is large.

The device consists of a tank, a lid, a heating system, a vent system, and a refining system. It removes hydrogen and other impurities from the aluminum melt.

The double degassing rotor, the heater protection sleeve and the thermocouple material are all silicon nitride materials independently developed.

Together with internal mixing spoiler design, it can ensure a good stable degassing effect.

According to the amount of processing, the equipment can be divided into single-chamber single rotor (1B1R), double-chamber double rotor (2B2R) and three-chamber three-rotor (3B3R).

The double rotor Aluminium Hydrogen Degassing Equipment is the main means of improving the comprehensive performance of the aluminum alloy by the aluminum alloy purification treatment process.

In the purification treatment process, the purification gas and the solvent are mixed, and the method of purifying the aluminum melt by the rotary injection of the graphite rotor is the most advanced treatment method in the world.

The working principle of the double-rotor Aluminium Hydrogen Degassing Equipment is that the rotating rotor breaks the nitrogen (or argon) blown into the aluminum melt into a large amount of dispersed bubbles and disperses them in the molten metal.

In the melt, the gas is separated by the partial pressure difference of the gas and the surface adsorption principle, absorbs the hydrogen in the melt, adsorbs the oxidized slag, and is taken out of the surface of the melt as the bubble rises, so that the melt is purified.

Due to the fine dispersion of the bubbles, it is uniformly mixed with the rotating melt, and then rotates in a spiral shape and slowly floats.

The contact time with the melt is long, and the gas flow generated by the continuous straight rise is not formed, thereby removing harmful hydrogen in the aluminum melt.

Sorry, the comment form is closed at this time.