19 4月 Degassing Machine Buy from Adtech China

Degassing Machine Buy from Adtech China

Please contact sales@adtechamm.com, or call +86 371 87095601

ADTECH keeps focusing on the manufacture of the metallurgical material.

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

1.Ceramic Foam Filter

2.Degassing Unit

3.Filter Box

4.Hot-top casting series

5.Roll casting nozzle

6.Flux series

7.Other Metallurgical Material

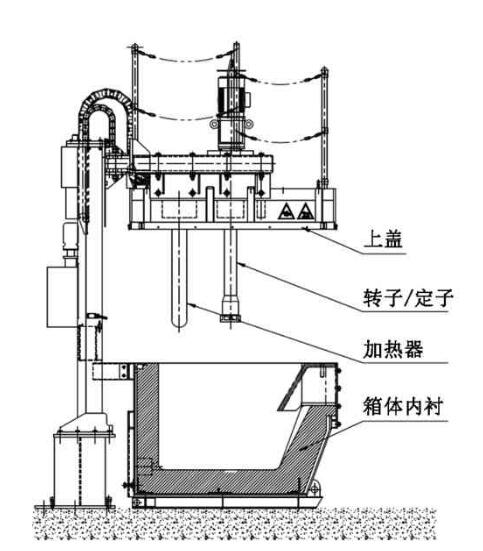

Degassing Machine Buy from Adtech, which is used in a fixed position to treat the metal contained in transfer ladles.

The machine is equipped with a rotating graphite tool (Iance), composed by a shaft and a rotor, through which the inert gas (nitrogen or argon) is blown into the melt, in the form of small bubbles.

In this way it is possible to eliminate the hydrogen dissolved in the alloy.

In addition, the same treatment allows the removal of the non-metallic inclusions present in the alloy, which are dragged by the gas bubbles toward the surface by effect of flotation.

Degassing Machine Performance:

1. The aluminum water online degasser mainly processes the molten aluminum liquid containing a certain amount of hydrogen and other residues (alkali metal, slag inclusion), and is removed after being treated by the degassing equipment.

2. The principle of treatment is gas flotation.

In Aluminium Degassing control, metal casting must complete two things

1. Prevent and minimize the introduction of hydrogen in the melt.

2. Pre-casting hydrogen. The Aluminium Degassing will focus on measurement and removal, usually introduced into the melt by a rotary degasser.

When the purge gas bubbles are introduced into the melt, they collect hydrogen as they float on the surface.

The best case is that these hydrogen-saturated bubbles leave the melt and reduce the hydrogen content.

In this case, from a thermodynamic point of view, the process efficiency is 100%, but as the gas content in the melt decreases, the equilibrium pressure of hydrogen in the bubble also decreases, so the purge gas required to remove residual hydrogen The amount must increase.

No Comments