02 4月 Foam Filter

Foam Filter

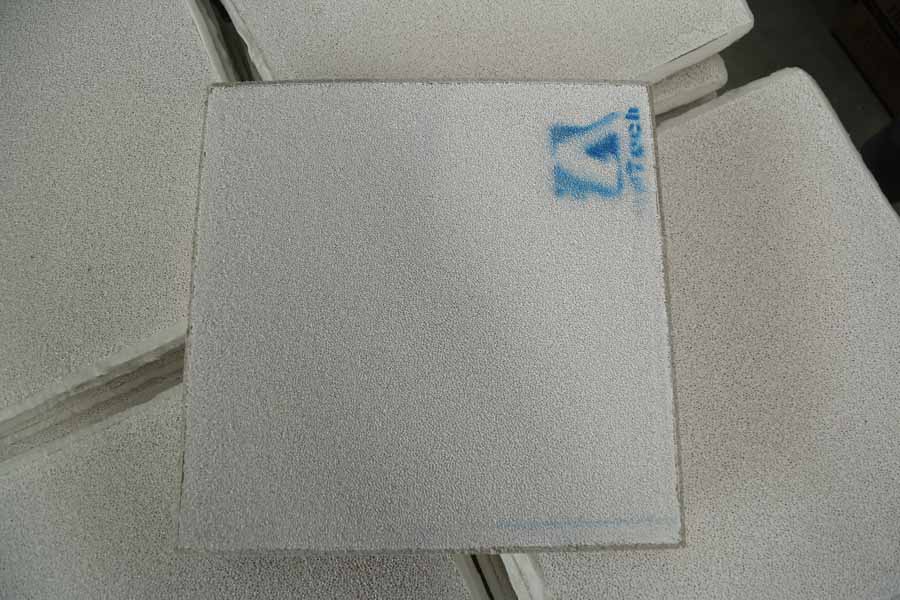

Aluminum Foam Filter is made of non-stick aluminum material.

It has the characteristics of non-stick aluminum. Foam Filter is white or milky white. It is suitable for the production of high quality and high requirements aluminum and aluminum alloy purification process through physical adsorption and Chemical action, which can effectively remove various oxidation inclusions generated during aluminum smelting process, thereby reducing casting defects, improving casting quality, and providing high-quality materials for further deep processing.

The choice of ceramic foam filter plate is based on the amount of impurities in the aluminum melt, the melt transfer flow rate, and the quality requirements of the final cast product.

set.

The amount of impurities is high, and the quality of the cast products is general. The foam ceramic filter plate with larger mesh holes can be selected, and a glass wire is added in front of the filter plate.

Cloth coarse Foam Filter. At this time, it is important to use a glass fiber cloth for coarse filtration in semi-continuous casting. It can intercept the slag and the slag washed by the launder when the eye is opened.

In order to prevent blockage of the filter plate.

The quality of the cast products is high, and the new type of foam ceramic filter with small mesh size is selected, for example, the AdTech Foam Filter uses a three-dimensional network structure and an organic bubble communicating with the pores as a carrier to invade it. In the thixotropy alumina material slurry, the tetragonal correction center distance automatic extrusion process is adopted, and the slurry is uniformly applied to the bubble skeleton of the carrier, and is baked and solidified at a high temperature of 1180 ° C. It is installed in the filter box for the impurity filtration of aluminum alloy liquid, and it can meet the high-value-added and high-tech aluminum alloy precision casting of aviation and transportation. Such as: computer hard disk, PS board base for printing, cans, jet turbine engine fan blades and other products, to achieve the desired cleanliness, get good results.

The Alumina Ceramic Foam Filter size is selected based on the flow rate through which the melt passes and the total throughput. The flow rate is large, the total throughput is large, and the filter plate has small holes, then

Use larger specifications.

Select the Alumina Ceramic Foam Filter should also look at its color, shoot its body, burn its contents.

The color is pure and no impurity, indicating that the material is uniform; the hand is not sticky, indicating that the surface is not sprayed with adhesive, and will not cause secondary pollution.

With one hand holding the filter plate, the other hand is clapping, and the filter plate is aptly beaten. The ceramsite residue is continuously dropped, indicating that it is a poor quality filter plate.

Secondary pollution of aluminum liquid.

Aluminum Foam Filter should be preheated before use.

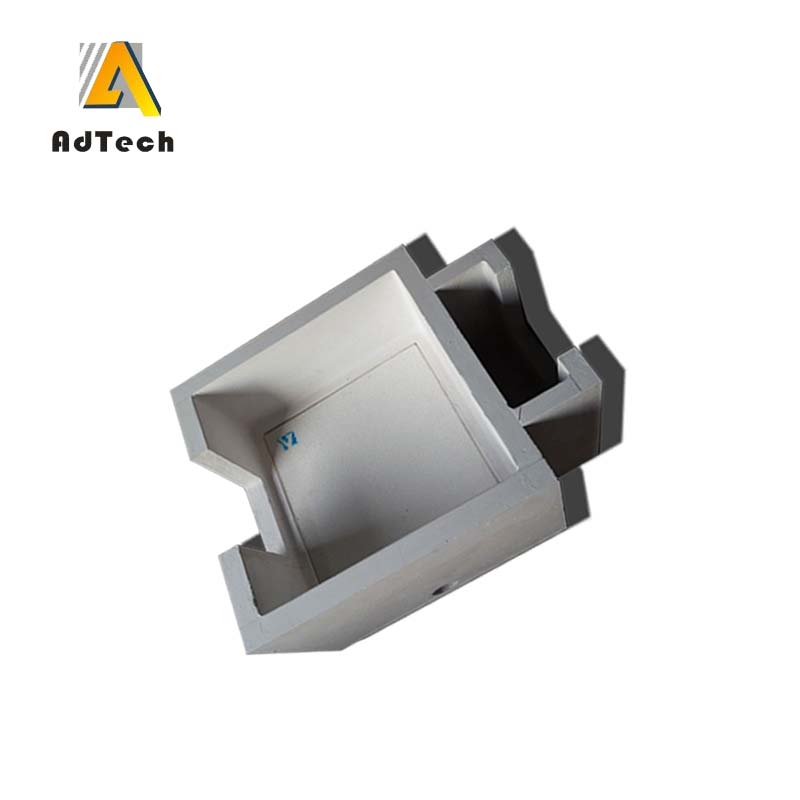

The filter plate is completely sealed in the Ceramic Foam Filter box to ensure that all the aluminum water passes through the filter plate, and the total amount of filtration must not exceed the specified limit. If the amount of slag in the aluminum water is too high, multiple pieces of filtration or reduction should be adopted. The amount is adjusted.

.jpg)

No Comments