.jpg)

23 7月 Ceramic Foam Filter Manufacturing Process

Ceramic Foam Filter Manufacturing Process

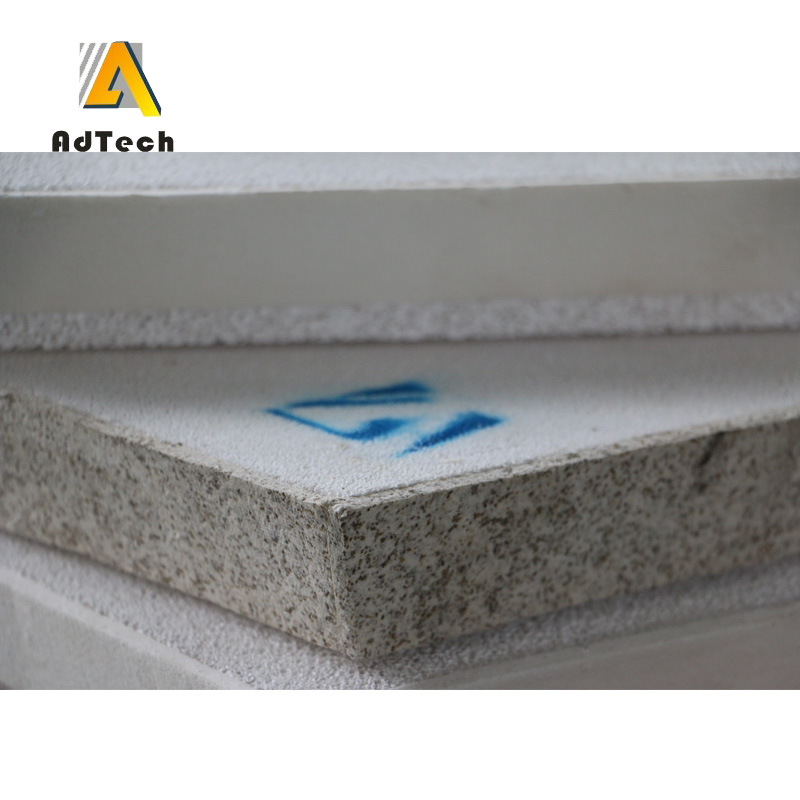

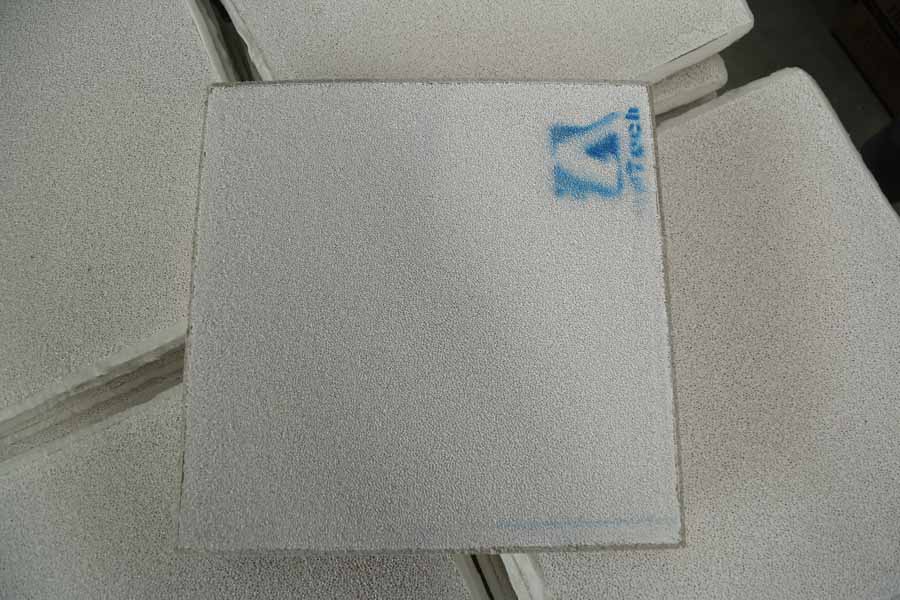

Filter-PZr filter plate is a high-adsorption ceramic filter plate (CFF) made of ZrO2 molten material sintered at high temperature. It is installed in the filter box for filtering impurity in aluminum alloy liquid to meet the aluminum alloy precision casting of high added value, high technical performance of aviation, transportation, etc. Such as, computer hard drives, semifinished micron aluminum foill, PS board base for printing, canning material, jet turbine engine fan blades and other products.

Filter-PAl filter plate adopts a three-dimensional network structure and an organic foam connected to the pores as a carrier, and invades it into the thixotropic Al2O3 material slurry, and uses a square-corrected center-distance automatic extrusion process to uniformly apply the slurry on the foam skeleton. And baked and solidified at a high temperature of 1,180 ° C. Installed in the filter box to filter impurity in aluminum alloy liquid, to meet the aluminum alloy precision casting of high value-added, high-tech performance of the aviation industry.

Filtration Efficiency

The filtration efficiency of the AdTech ceramic filter plate depends on the pore size of the filter plate, the size and type of inclusions (density, wetting characteristics) and the speed at which the molten metal passes through the filter plate.

It is surrounded and sealed by expanded gasket with 200% expanding above 450°C to prevent floating and leakage of aluminum liquid through the contact surface.

Filtered by the adsorption principle, it can effectively remove large inclusions in the aluminum liquid, and effectively adsorb fine inclusions of micron size, and the filtration efficiency of the same ppi is high.

Sealing Gasket

A sealing gasket is applied around the ceramic filter plate to act on the contact surface of the filter plate and the filter box to prevent leakage of the aluminum liquid through the contact surface. Our filter plates are made of three different types of sealing gaskets including fiber paper sealing; fiber cotton sealing; expandable gasket sealing.

.jpg)

No Comments