13 8月 Ceramic Foam Filter With Fiber Blanket Sides

Ceramic Foam Filter With Fiber Blanket Sides

It’s very important to choose and design Ceramic Foam Filter model & filter seat correctly according to casting types and pouring weight. The general principle is that the whole gating system should be a system without pressure to ensure that the molten metal liquid filling mould smoothly. Ratio of the sectional area will be the main point.

Advantages

Increased Fluidity

Removal of inclusions makes the metal more fluid, resulting in easier mold fill, better cast structure, and better thin section castability.

Ceramic Foam Filter :

1.Expandable Gasket Sealing

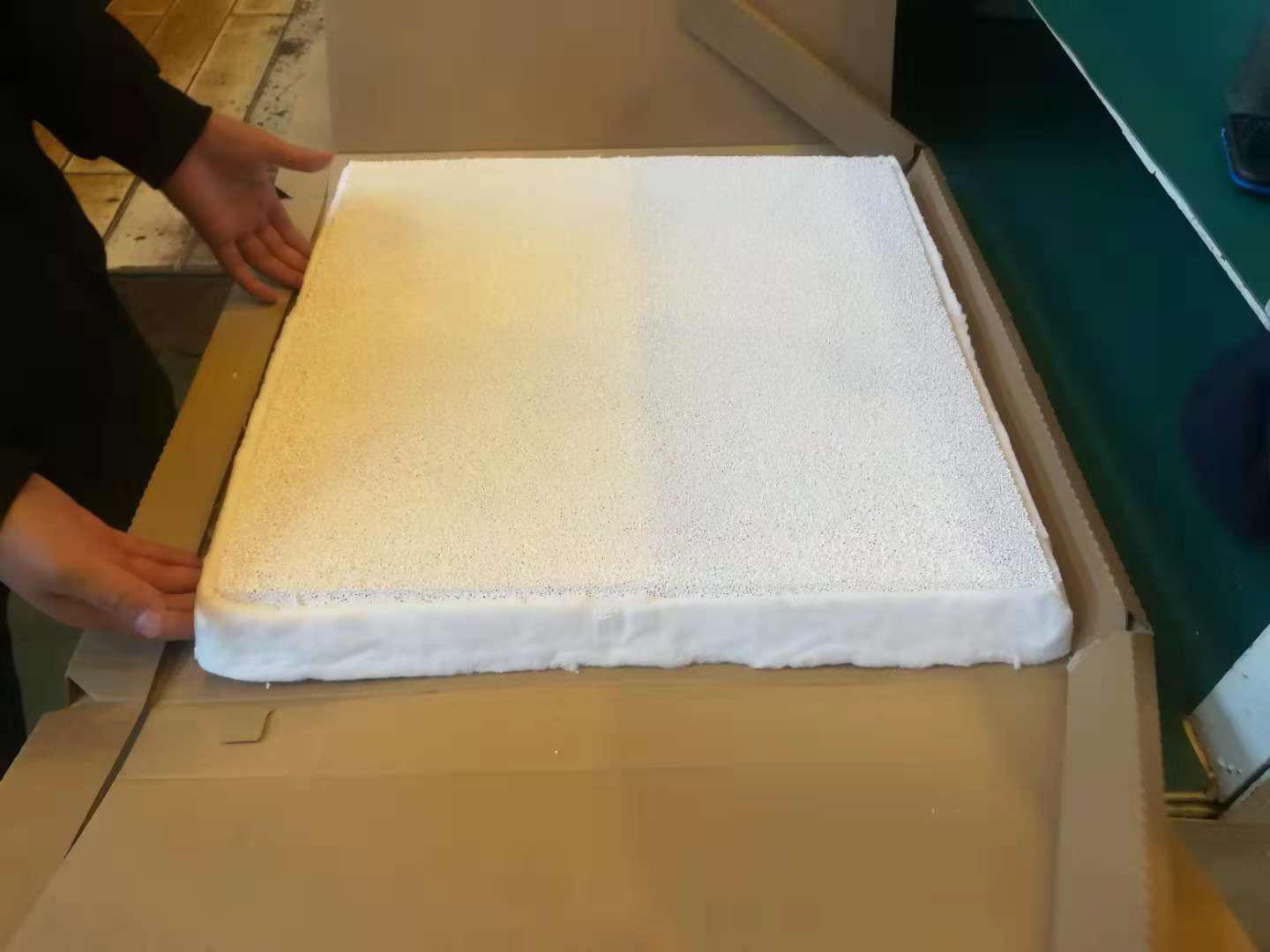

2.Fiber Cotton Sealing

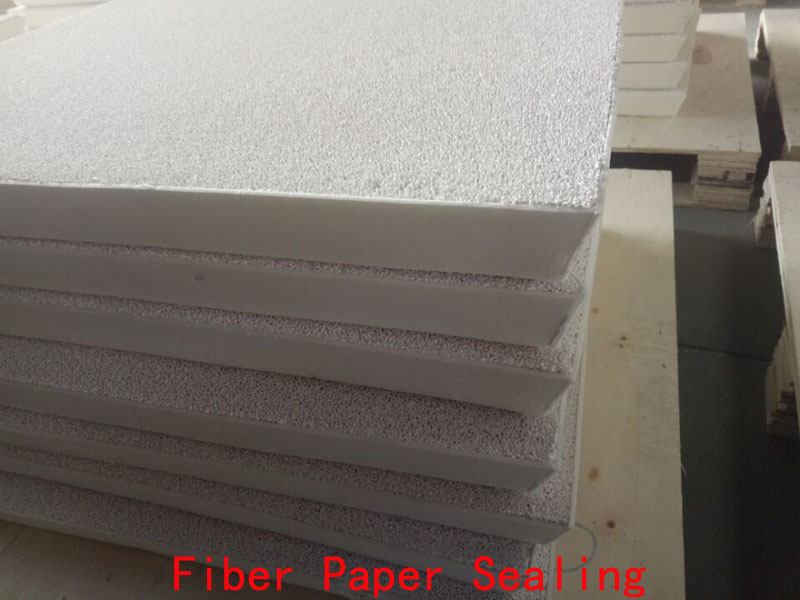

3.Fiber Paper Sealing

A sealing gasket is applied around the ceramic filter plate to act on the contact surface of the filter plate and the filter box to prevent leakage of the aluminum liquid through the contact surface. Our filter plates are made of 3 types of sealing gaskets including fiber paper sealing;fiber cotton sealing;expandable gasket sealing.

.jpg)

No Comments