08 4月 Nitrogen Degassing Machine

Nitrogen Degassing Machine

Aluminium and aluminium alloys, like the majority of metals in their liquid state can dissolve significant quantities of gas.

The most soluble gas in molten metal is hydrogen. Hydrogen bubbles present in molten metal materialise as porosity during the solidification of the metal. This porosity is harmful to the mechanical properties, sealing and aesthetic appearance of the moulded parts.

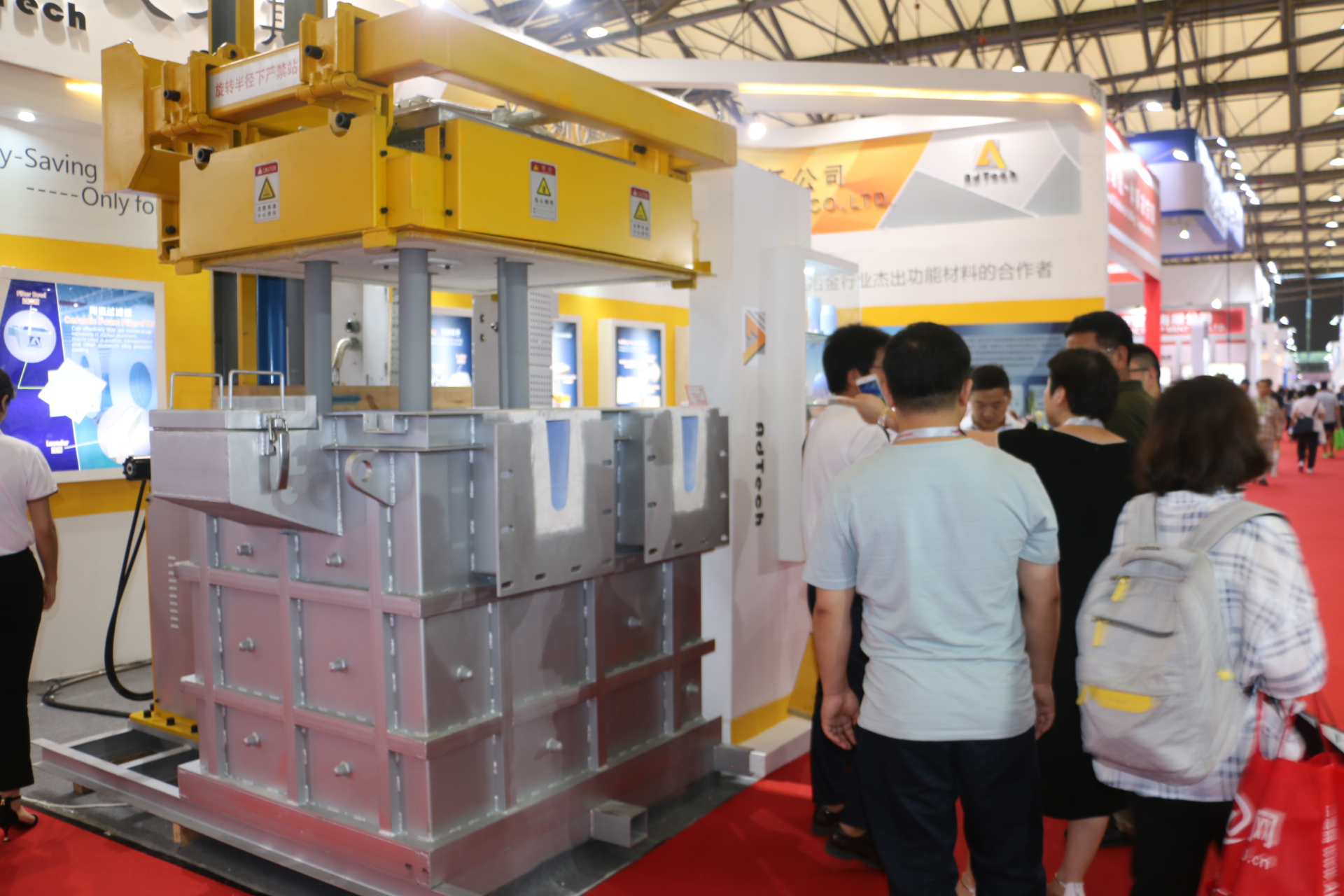

ADTECH has developed three processes of Nitrogen Degassing Machine which enable the degassing of aluminium and its alloys :

1.Chemical/manual process through addition of degassing tablets such as Desydral N70P or Desydral N71P.

2.Chemical/manual process through injection of a neutral gas (usually Nitrogen) through a degassing air stem closed with a porous plug

3.Chemical / automatic process through degassing machines such as Rotoxal.

Various parts of the Nitrogen Degassing Machine such as thermocouple protection tubes, heater protection tubes, stalks and degassing rotor shafts are being used in the processes through melting furnaces to casting tables in the aluminium industry. Silicon nitride fine ceramics is the best material to suit a variety of demands like.

1.outstanding corrosion resistance to molten aluminium alloys and flux,

2.very good gas tightness,

3.excellent oxidation resistance up to 800°C and therefore long lifetime,

4.good thermal shock resistance,

5.the highest mechanical strength among ceramics,

6.very good wear resistance for rotating parts and least but not last

7.an exceptional acid resistance against acids such as HCl and H2SO4 which allows acid cleaning of the parts.

Thermocouple and Heater Protection Tubes

Hi-Cera SN makes an excellent thermocouple protection tube considering the outstanding features. These tubes are maintenance free, have a long service life and are easy to handle.

Hi-Cera SN heater protection tubes have excellent corrosion resistance, high mechanical strength and outstanding shock resistance. Using this material ensures a long lifetime. Hi-Cera SN heater tubes are available for both vertical and horizontal applications.

Degassing Rotor Shafts, Wheels and Equipment

Before using the molten aluminium for casting, it is necessary to remove hydrogen gas from the melt in order to avoid bubbles in the cast aluminium parts. This can be done by using a rotor, rotating in the aluminium melt and purging the molten aluminium through the shaft with Argon gas. Hi-Cera SN rotor shafts and wheels exhibit exceptional wear and oxidation resistance compared to a graphite rotors. They assure stable high hydrogen removal efficiency and have a long lifetime. The excellent thermal shock resistance and the original impeller design permit insertion into and withdrawal from molten aluminium without preheating. The original design of the TKR rotor wheel results in high gas dispersability and makes hydrogen removal efficiency superior. Hi-Cera SN rotor shafts and wheels are suitable for both in-line and batch degassing systems.

Aboli Prashant Khele

Posted at 09:34h, 01 1月Inline degassing machine for bullet casting plant 15MT/hr capacity required

Inline degassing machine 20mt/hr please mail proposal for both of them