20 6月 Metallurgy Factory Molten Aluminum Degassing Machine Parts

Metallurgy Factory Molten Aluminum Degassing Machine Parts

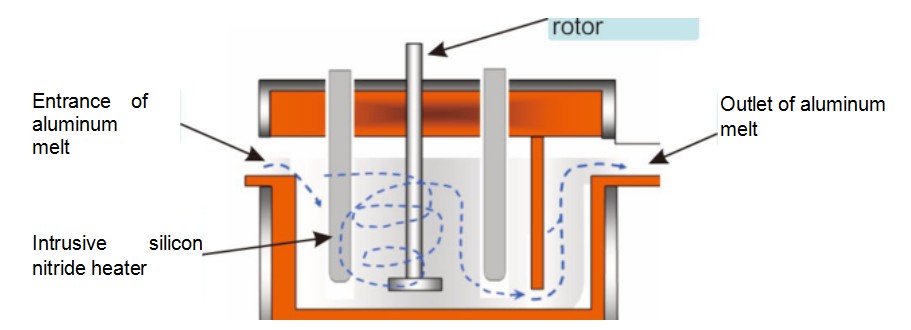

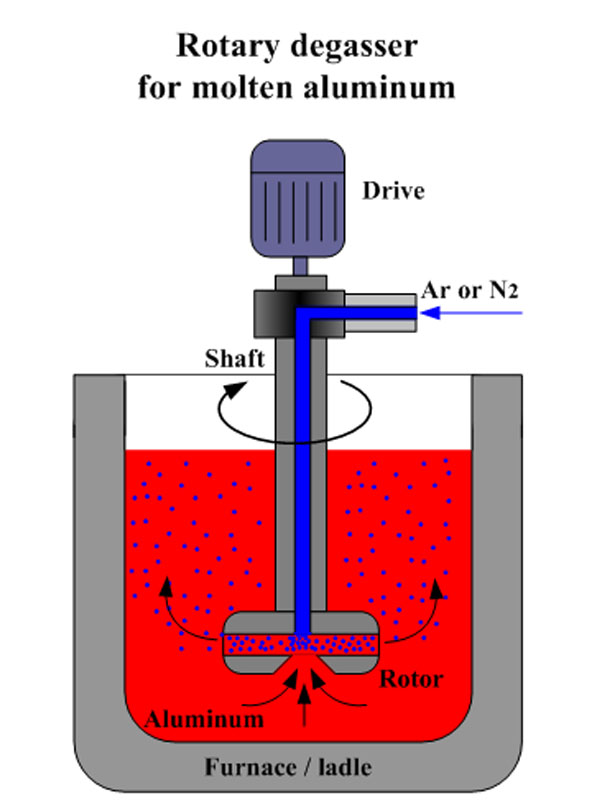

The on-line degassing equipment mainly deals with molten aluminum which contains a certain amount of hydrogen and other residues(alkali metals, inclusions).

The principle of on-line degassing equipment is gas flotation principle with the process gases (inert gas or mixture of inert gas and chlorine gas). The rotor takes the process gasses into molten aluminum and smash the gases into dispersed tiny bubbles and the bubbles rise to molten aluminum surface

1.Hydrogen is being absorbed into bubbles and is being removed.

2.Alkali metals are removed as the metals react with chlorine gas to form chlorides.

3.The inclusions are trapped by bubbles and then rise to the surface of the melt to form dregs.

Degassing Machine Parts-Sealing Structure Design

Outer wall temperature of online degassing device should be controlled at 65t or below.

The sealing structure is designed by fully sealing the box cover, the box body and the aluminum melt inlet and outlet. It can effectively prevent the slag from the secondary oxidation of aluminum melt and improve the degassing effect.

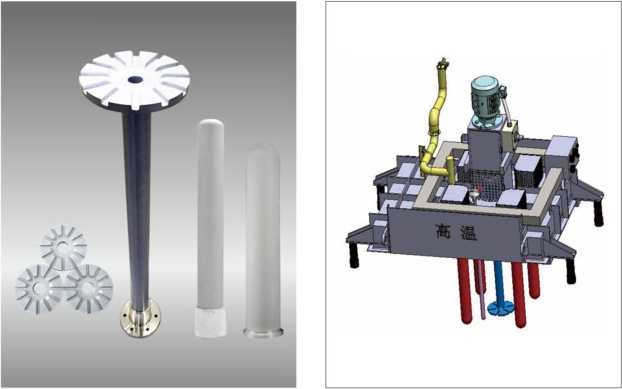

Degassing Machine Parts-Box Structure Design

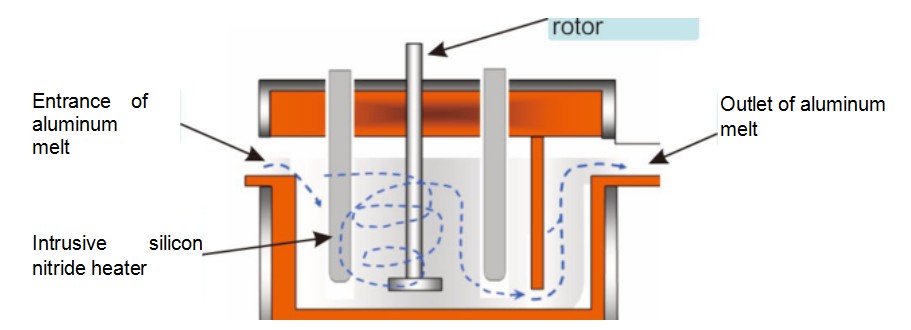

The on-line degassing equipment has an ultra-long life and the furnace body adopts the new manufacturing technology of high fused silica. The degassing rotor, heater protection sleeve and thermocouple protection sleeve are made of silicon nitride (Si3N4) ceramic with high technical performance of aluminum production technology.

Degassing Machine Parts-Rotor Standard Design

Using silicon nitride material, the service life is more than 2 years. The design of stepless speed control of 0-600 rpm can break the bubble to the maximum extent, and spread the bubbles throughout the inner cavity.

Immersion heater protection sleeve

Sorry, the comment form is closed at this time.