05 11月 Making Porous Ceramic Filter

Making Porous Ceramic Filter

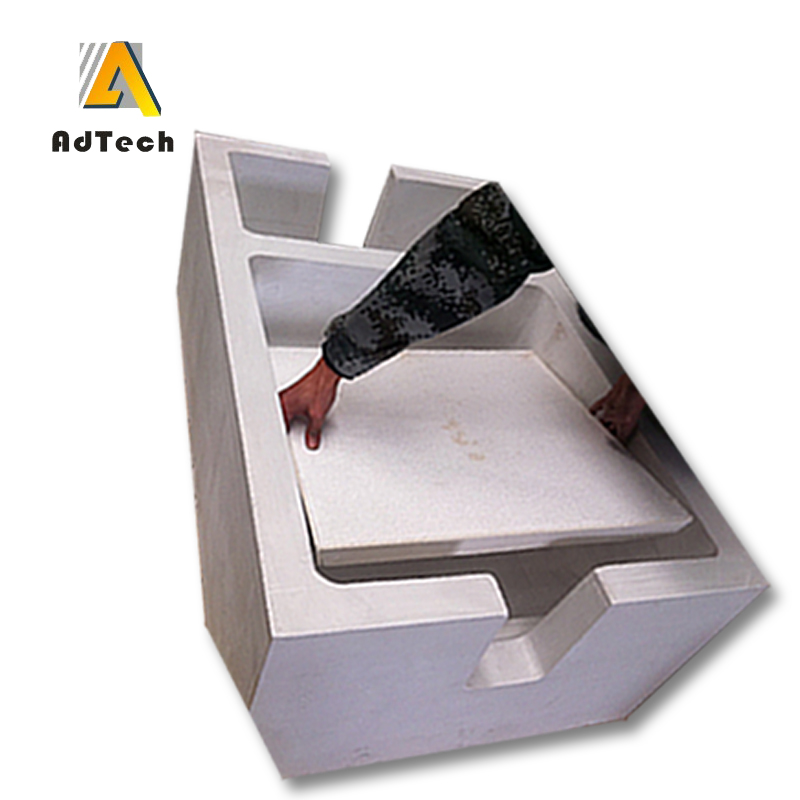

There are many impurities, and the quality of cast products is general. Ceramic filter plates with larger meshes are available, and a glass cloth coarse filter is added in front of the filter plates. At this time, semi-continuous casting is important for coarse filtration with a glass cloth. It can intercept the slag from the opening of the eye and the slag washed out by the launder to prevent clogging of the filter plate.

The quality of cast products is high, and the new type of foam ceramic filter with small mesh size is selected.

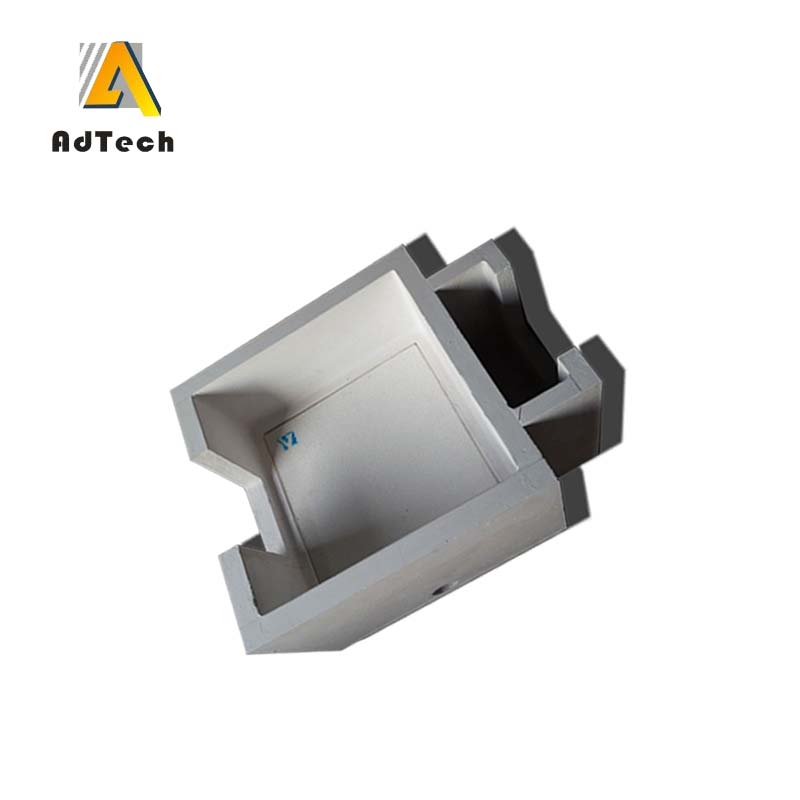

The filter plate size is selected based on the flow rate through which the melt passes and the total throughput.

The color is pure and no impurity, indicating that the material is uniform; the hand is not sticky, indicating that the surface is not sprayed with adhesive, and will not cause secondary pollution.

The effective specific surface area or porosity calculation of the foam should be carefully evaluated when purchasing the filter. The mesh surface homogenization state of the filter plate can be observed, and then the cross-sectional mesh homogenization state is observed. If possible, the porosity can be calculated by the drainage method. The three-dimensional mesh is homogeneous and the porosity is relatively large, which is an excellent ceramic filter plate.

Sorry, the comment form is closed at this time.