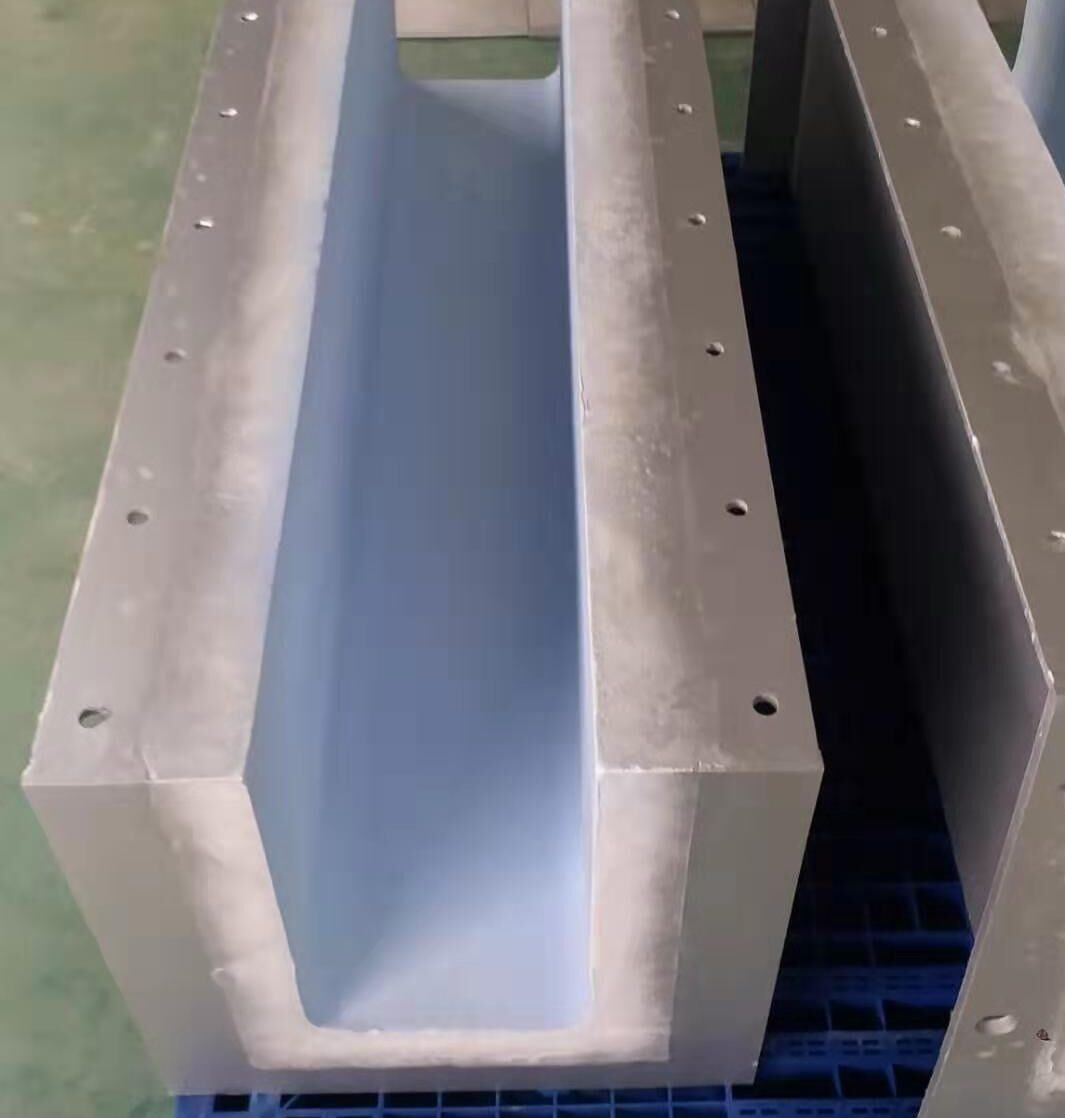

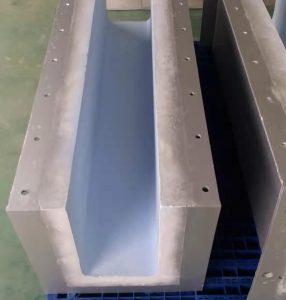

22 6月 Launder Systems

Launder Systems has an ultra-long life liner, adopts new high-silicon molten material molding technology, has strong corrosion resistance, non-stick aluminum, and no pollution to aluminum liquid. It meets the production of aluminum products with high added value and high technical performance requirements. Technical know-how.

Launder Systems product performance

1. It can directly catch the flame, resist high-speed airflow scouring, and have strong wind erosion resistance

2. Stable high-temperature performance, thermal shock resistance, low thermal fusion, and high compressive strength under high-temperature

3. Thickness is proportional to bulk density

4. Due to the addition of an electrodeless bonding agent, the product has high compressive strength and good toughness

5. Safe and convenient

Launder Systems are silicate fiber products, which are mainly used in the distribution and transmission of aluminum liquid with high thermal insulation requirements, such as movable runners on casting and rolling, and distributor runners on the same level of casting discs.

Product advantages

1. Good thermal insulation performance, reasonable design, and extended service life;

2. Adopt noble molten material for integral molding, high dimensional accuracy;

3. The lining has high strength, erosion resistance, thermal shock resistance, and smooth surface;

4. The lining has strong corrosion resistance to aluminum, zinc, and magnesium alloys, which enhances the use of molten metal transfer equipment and enhances the service life of special alloys;

5. The temperature drop of the metal liquid during use shall be within 2°C per meter, resistant to erosion, thermal shock, and smooth surface.

Product quality description

material:

Refractory composite material. The materials are non-toxic and harmless, and there is no smoke or odor during use.

Thermal shock resistance

Use temperature ~ room temperature air cooling repeatedly, the product does not crack, or change shape and color.

The heat-resistant and heat-insulated special parts produced for the special requirements of the metal casting industry can effectively resist the impact force of the metal solution. Its hardness and density are several times higher than the traditional refractory fiber-shaped parts. It is a high-strength temperature-resistant partition. Hot-shaped parts. During use, it is not wetted or eroded by most molten metals and has good anti-wear and anti-stripping properties.

The product is a non-brittle material with high strength, tough texture, and strong resistance to wind erosion.

Can directly contact the flame for a hot surface.

Product size is accurate, excellent construction and installation performance.

Sorry, the comment form is closed at this time.