05 11月 Aluminum liquid refining agent

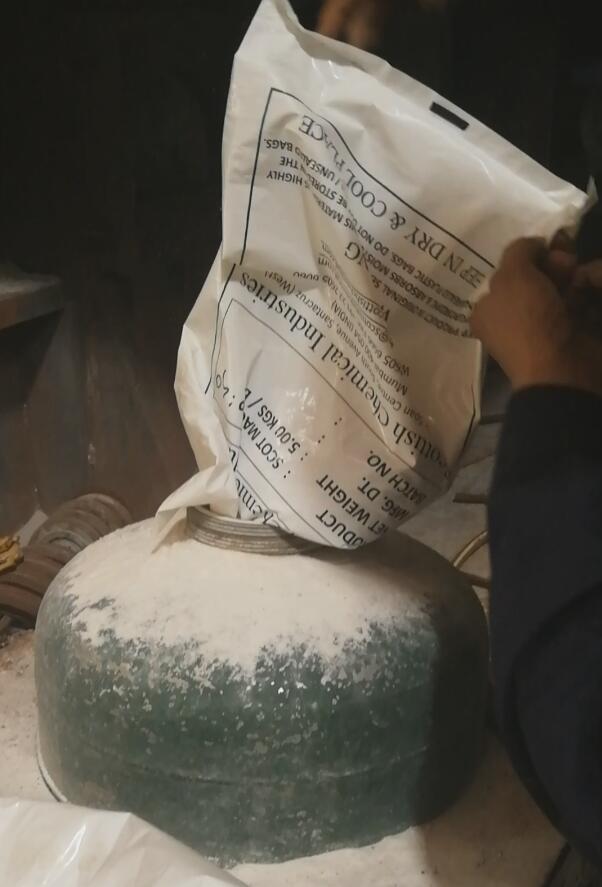

Aluminum liquid refining agent

Aluminum liquid refining agent is a white powder or granular flux, which is prepared by drying a plurality of inorganic salts and mixing them in a certain ratio, and is mainly used for removing hydrogen and floating oxidized slag inside the aluminum liquid.

Characteristics: Some components in the refining agent are easily decomposed at high temperature, and the generated gas is easy to react with hydrogen, and has strong adsorption force with slag and quickly escapes from the melt. The other components have the function of clearing slag.

Scope of application: Suitable for aluminum alloys of common grades (alloys with high magnesium content and aluminum-magnesium alloys), and pure aluminum smelting, degassing refining and slag removal.

Aluminum liquid refining agent usage

The refining agent is sprinkled on the liquid surface, and is quickly pressed into the aluminum liquid. After being fully stirred, it is allowed to stand and slag; if it is sprayed, the refining agent is sprayed into the aluminum liquid with an inert gas.

Aluminum liquid refining agent principle

AdTech refining agent is white (slightly gray) powdery fine particles, the main components are chlorine salt and fluoride salt, and other compounds, after proper heat treatment and sieving, the particle size is uniform.

Conducive to the uniformization of the refining tank under the action of carrier gas (N 2 or Ar) into the lower layer of aluminum liquid, through the physical and chemical changes in the formation of numerous small bubbles in the aluminum liquid and aluminum liquid in full contact, separation of [H] in the aluminum liquid Other harmful gases.

At the same time, some substances contained in the refining agent can strongly adsorb and melt the oxides and suspended matter in the melt and adhere to the bubbles together, and bring them to the surface of the aluminum liquid as the bubbles rise, thereby achieving refining such as degassing and slag removal. The purpose of purification.

Environmentally friendly and economical, it meets the high-value-added, high-tech performance of aluminum alloy precision casting for aviation and transportation.

Rotary Degassing And Fluxing Unit For Aluminum Alloys

Posted at 09:02h, 14 11月[…] Degassing And Fluxing Unit For Aluminum Alloys Advantages It has extremely excellent corrosion resistance (except hydrofluoric acid) for all […]

Kurniawan

Posted at 05:14h, 06 2月I am looking flux for Alumunium smelter to get the alumunium inggot production from slag (Bouxite) can you recommend it for me? my mobile/WA/Wechat:+62817211678