19 10月 Aluminum Water Refining Agent

Aluminum Water Refining Agent

The aluminum water refining agent mainly removes the hydrogen and floating oxidized slag inside the aluminum water and the high-temperature melt purification (refining) treatment of the aluminum alloy, and the basic function is to remove the internal inclusions and hydrogen in the high-temperature melt. This makes the aluminum liquid more pure and also has the effect of clearing the slag. Some members of the aluminum water refining agent are easy to decompose at high temperature, and the generated gas can react with hydrogen, and can strongly adsorb the slag and quickly escape from the melt to play a role in clearing the slag.

Aluminum water refining agent can be used in a variety of aluminum alloy melts, can be used for pure aluminum smelting, to refine and slag. It is only necessary to sprinkle the refining agent on the surface during use, and then the refining agent is quickly dissolved in the aluminum liquid and then thoroughly stirred. If a jet is used, it is better to use an inert gas to inject the refining agent, for example, nitrogen and argon can be selected.

Pay special attention when spraying. Start by supplying air before starting the powder. At the end, stop the powder before stopping the gas. This is to prevent the aluminum refining agent from clogging the nozzle. If the molten aluminum refining agent is found to have moisture or knot. In the case of a block, you can continue to use it by opening the package and drying it under the sun. It is necessary to add enough molten aluminum refining agent on the surface of the aluminum liquid, so that the surface of the aluminum liquid can be uniformly covered to protect the aluminum liquid from being oxidized by air, and the amount to be added needs to be added according to the ratio.

The aluminum water refining agent has the advantages of being smokeless, odorless, dust-free, and easy to operate. For example, the special bell jar for melting treatment is better, and the plant and equipment are not corroded. The refining agent has a good degassing effect, and under normal conditions, the pinhole degree of 1-2 can be achieved. The slag is dry, loose and light, and has good separation from the aluminum alloy liquid and is easy to remove.

After the refining treatment, the surface of the aluminum liquid should have a thin layer of flux floating up to the liquid surface. Indicates that the reaction is good, and if there is no such flux, the operation is poor. After 5 to 8 minutes of standing after the end of the treatment (using the conventional sample including the skin test), no air bubbles should escape to the liquid surface, indicating that the aluminum liquid is well treated.

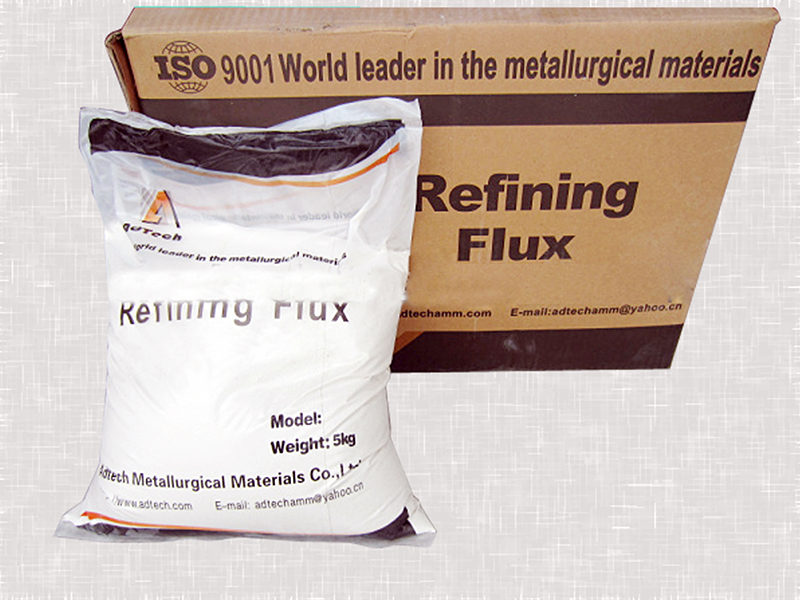

Aluminium Refining Agent is developed by Adtech Metallurgical Materials Co., Ltd. to develop, produce and sell refining agents for degassing and slagging of aluminum metal in aluminum alloy casting process. AdTech’s refining agent uses unique technology. It improves the traditional degassing and slag removal effect in molten metal, and is applied in the casting and rolling process of multi-series aluminum alloy products: micron-sized aluminum foil wool, PS board base for printing, can material, elastic packaging material, rail transit Purification of the degassing and slag purity of the molten metal in the process of casting aluminum alloy raw materials such as aerospace products and cable wires.

No Comments