14 9月 Alu Refractory Tap Out Cone

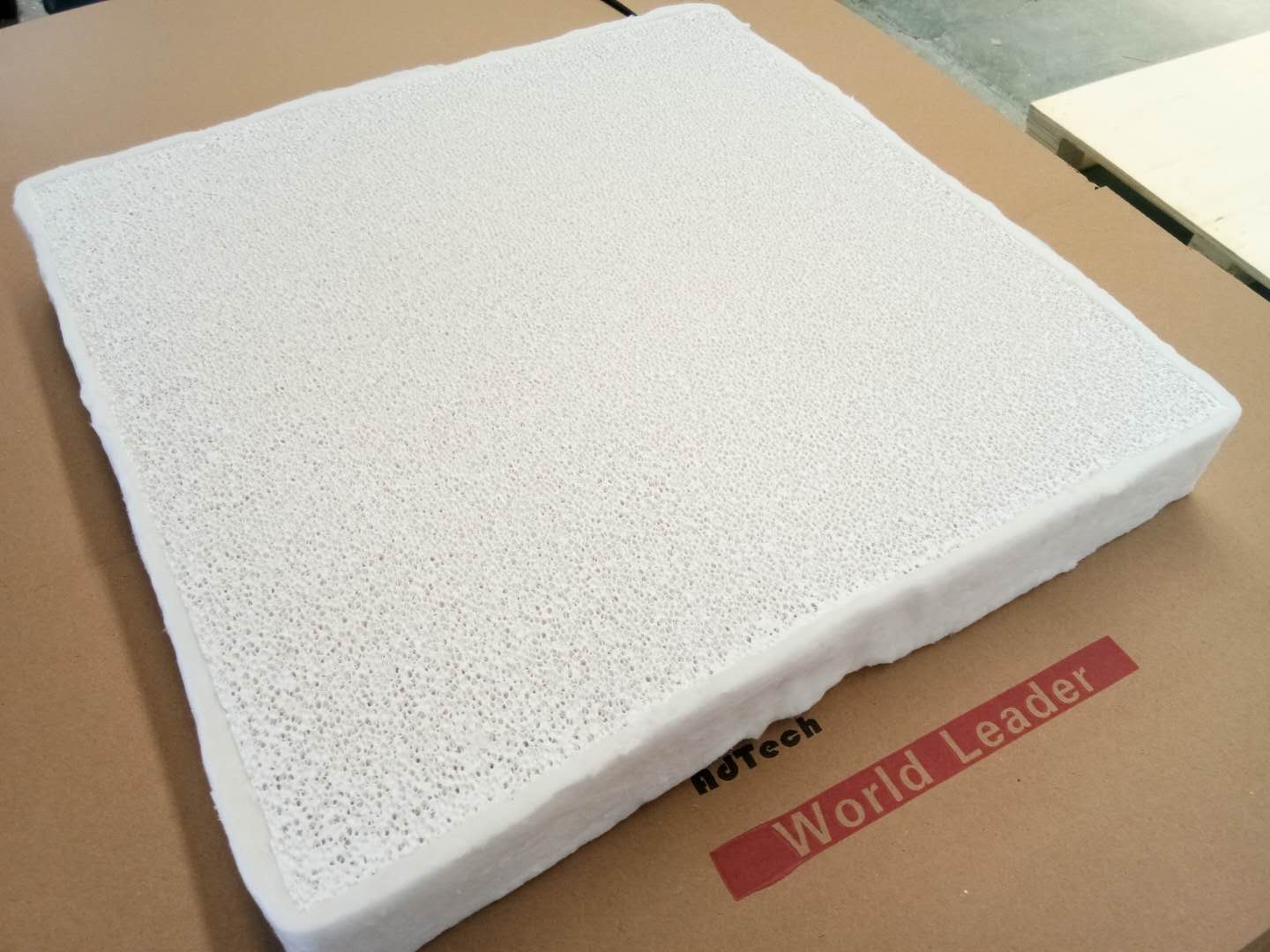

Alu Refractory Tap Out Cone, also known as high temperature TAP OUT CONE, is made of high alumina fiber. The original manual process was changed to a vacuum suction filter automatic equipment forming process. The production efficiency is high, the quality stability is high, and the yield...