09 9月 Porous Ceramic Filter Factory

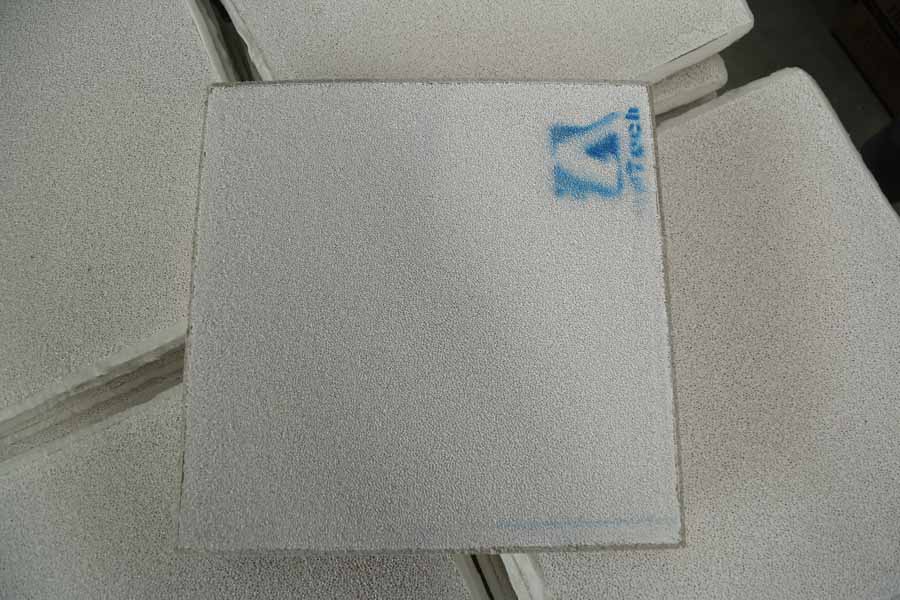

Porous Ceramic Filter Factory meets high quality standards and has excellent homogeneity.

They have a variety of pore sizes and can be used for Ceramic Foam Filter of all common metals such as iron, stainless steel and aluminum.

As an excellent Porous Ceramic Filter Factory, we have a deep understanding of customer needs and industrial requirements.

With the highest quality standards, we ensure the extraordinary homogeneity of the filter foam, thus achieving maximum effectiveness for the final product.

All our products have an unusually homogeneous foam structure and have solid wetting and recovery properties.

Various apertures-suitable for all applications

We provide one of the most extensive PUR foam product portfolios on the market and produce polyurethane foams with various pore sizes. Our pore sizes range from 20 to 70 ppi, allowing our customers to produce Porous Ceramic Filter for all common aluminum and alloys.

Porous Ceramic Filter Factory introduces recycled aluminum recycling

Recycled aluminum is made of recycled aluminum parts or scrap and scrap aluminum wires in the process of producing aluminum products as the main raw materials. Aluminum ingots that meet the requirements of various standards are produced by smelting.

This kind of aluminum ingot adopts recycled scrap aluminum, and has a lower production cost, and it is the reuse of natural resources, and has strong vitality, especially in the current rapid development of science and technology and the continuous improvement of people’s life quality today, product updates The frequency of replacement is accelerated.

The recycling and comprehensive utilization of waste products has become an important issue for the sustainable development of mankind, and the production of secondary aluminum has emerged in this form and has excellent prospects.

Since the raw material of secondary aluminum is mainly scrap aluminum, there are scrap aluminum castings (mainly Al-Si alloy), scrap aluminum forgings (Al-Mg-Mn, Al-Cu-Mn and other alloys), and profiles (Al-Mn, Al-Mg and other alloys) waste cables (mainly pure aluminum) and other materials.

How to prepare such a variety of complex raw materials into qualified recycled aluminum ingots is the core issue of recycled aluminum production.

The first step of the secondary aluminum production process is the sorting and classification process of waste and miscellaneous aluminum.

The finer the sorting and the more accurate the classification, the easier it is to control the chemical composition of recycled aluminum.

Scrap aluminum parts often have many inlays. These inlays are mainly non-aluminum parts made of steel or copper alloy. If they are not pulled out in time during the smelting process, it will cause some unnecessary additions to the secondary aluminum composition. Composition (such as Fe, Cu, etc.).

Therefore, in the early stage of secondary aluminum smelting, that is, when the waste aluminum is just melted, there must be a process of stripping inserts (commonly known as the stripping process).

Pull out the inserts from the waste aluminum parts, and the more timely and clean it is, the easier it is to control the chemical composition of the recycled aluminum.

The temperature of the melt should not be too high when ironing, as the temperature rise will cause the Fe and Cu elements in the insert to dissolve into the molten aluminum.

Scrap aluminum materials collected from various places are inevitably dirty on the surface due to various reasons, and some are severely rusted. These dirt and rusted surfaces will enter the molten pool to form slag phases and oxidation inclusions during melting, which will seriously damage the metallurgical quality of secondary aluminum. .

Removal of these slag phases and oxide inclusions is also one of the important processes in the secondary aluminum smelting process.

Multi-stage purification is used, that is, a rough purification is carried out first, and the composition is adjusted and then a secondary rare earth fine change is carried out, and then inert gas is blown to further strengthen the refining effect, which can effectively remove the inclusions in the aluminum melt.

Sorry, the comment form is closed at this time.