21 10月 Aluminium Alloy Foundry Filter

Aluminium Alloy Foundry Filter is used to filter non-metallic solid inclusions in aluminum and aluminum alloy solutions. It is cost-effective. It uses high-open-pore structure sponge and high-purity ceramic materials.

After strict quality control, the pore size is large, the through-hole rate is high, the sintering is sufficient, the flexural and compressive strength is good, and high efficiency filtration is ensured.

Aluminium Alloy Foundry Filter is widely used in the filtration and purification of various aluminum and aluminum alloy solutions, such as continuous casting, semi-continuous casting, gravity casting, low pressure casting, etc. In addition to general specifications, it can also be designed according to customer requirements.

Foundry Filter features

It can effectively remove the larger inclusions in the molten aluminum, absorb the micron-sized inclusion particles, improve the surface quality, improve the product performance, improve the organization, and increase the yield. It is widely used in the production fields of aluminum profile, aluminum foil, aluminum alloy and so on.

Here Adtech introduces the production process of foam ceramic filter

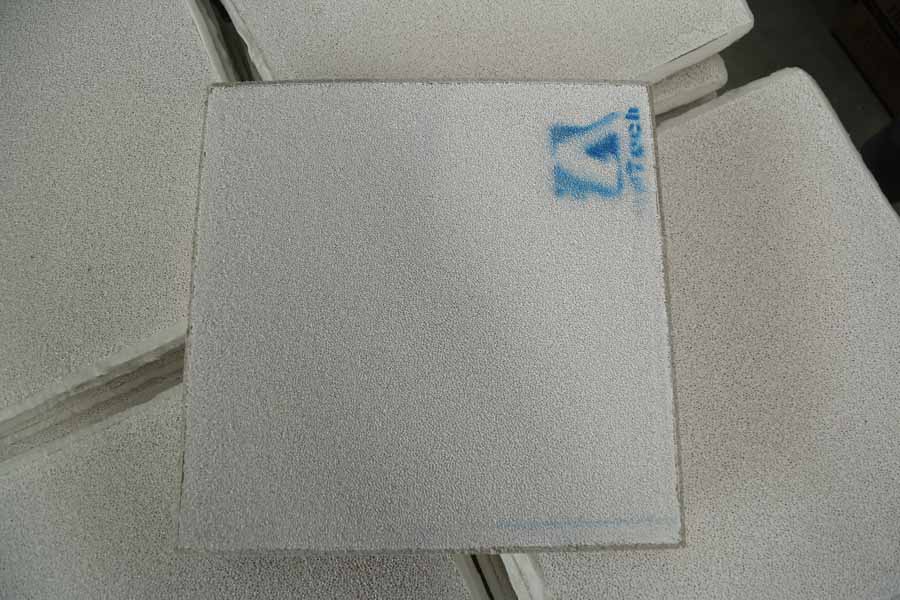

The three-dimensional network structure and porous foam organic foam are used as the carrier to intrude into the special ceramic slurry with thixotropic properties, and the ceramic slurry is uniformly coated on the carrier skeleton by a special roll extrusion process. Then, it is dried and cured, and then fired at high temperature.

Instructions for use of Aluminium Alloy Foundry Filter

1. Clean the filter box.

2. Gently put the filter plate into the filter box, and press the gasket around the filter plate by hand to prevent the flow of aluminum liquid.

3. Evenly preheat the filter box and the filter plate to make it close to the temperature of the molten aluminum. Preheat to remove moisture and promote preliminary transient filtration. Electric heating or gas heating can be used for preheating. Under normal circumstances, it takes about 15-30 minutes.

4. Pay attention to the replacement of the aluminum water head during the casting process. The normal starting pressure head is 100-150mm. When the molten aluminum begins to pass, the indenter drops below 75-100mm, and then the indenter slowly rises.

5. In the normal filtration process, avoid impact and vibration of the filter plate. At the same time, the cleaning tank should be filled with molten aluminum to prevent the molten aluminum from being disturbed too much.

6. After the filtration is completed, remove the ceramic foam filter plate in time and clean the filter box.

Product specification model: This standard is the product model, represented by the current common name P. The number in front of the English letter P indicates the hole density of the product, corresponding to the uniformity of the hole. For example, the 10P type is a ceramic foam filter product with a uniformity of 7-13 pores in any 25.4 mm length.

Sorry, the comment form is closed at this time.