28 6月 Ceramic foam filter for casting aluminum

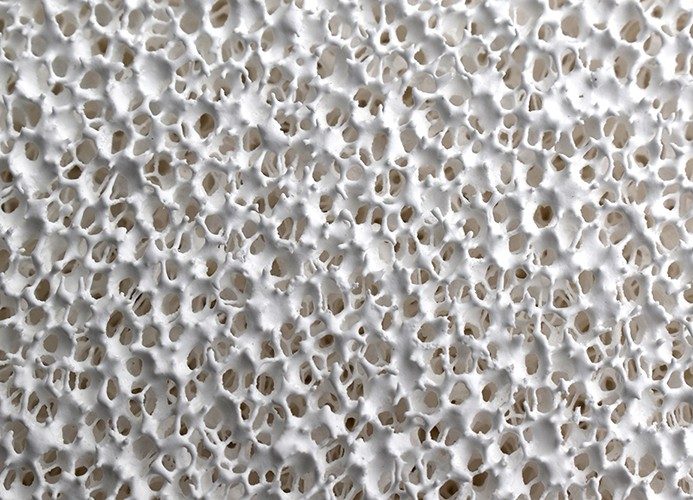

Ceramic foam filter for casting aluminum

Two series of ceramic foam filters for casting aluminum:

- series for continuous casting of aluminum with direct cooling (DC casting) - and for casting aluminum in the mold, a shaped casting Al2O3 ceramic foam filter - standard filter Special filter type with increased efficiency and capacity (higher open porosity is achieved, i.e., the filter has fewer clogged pores inside the filter)Sizes:

10 '' ... 26 ’’ (production of the filter under the Customer is possible) Porosity, PPI: 10 ... 70 Bending Strength: approx. 1.5 MPa The density of the material: 2.2 g. / cm3 Operating temperature: + 1000 - 1200 оС