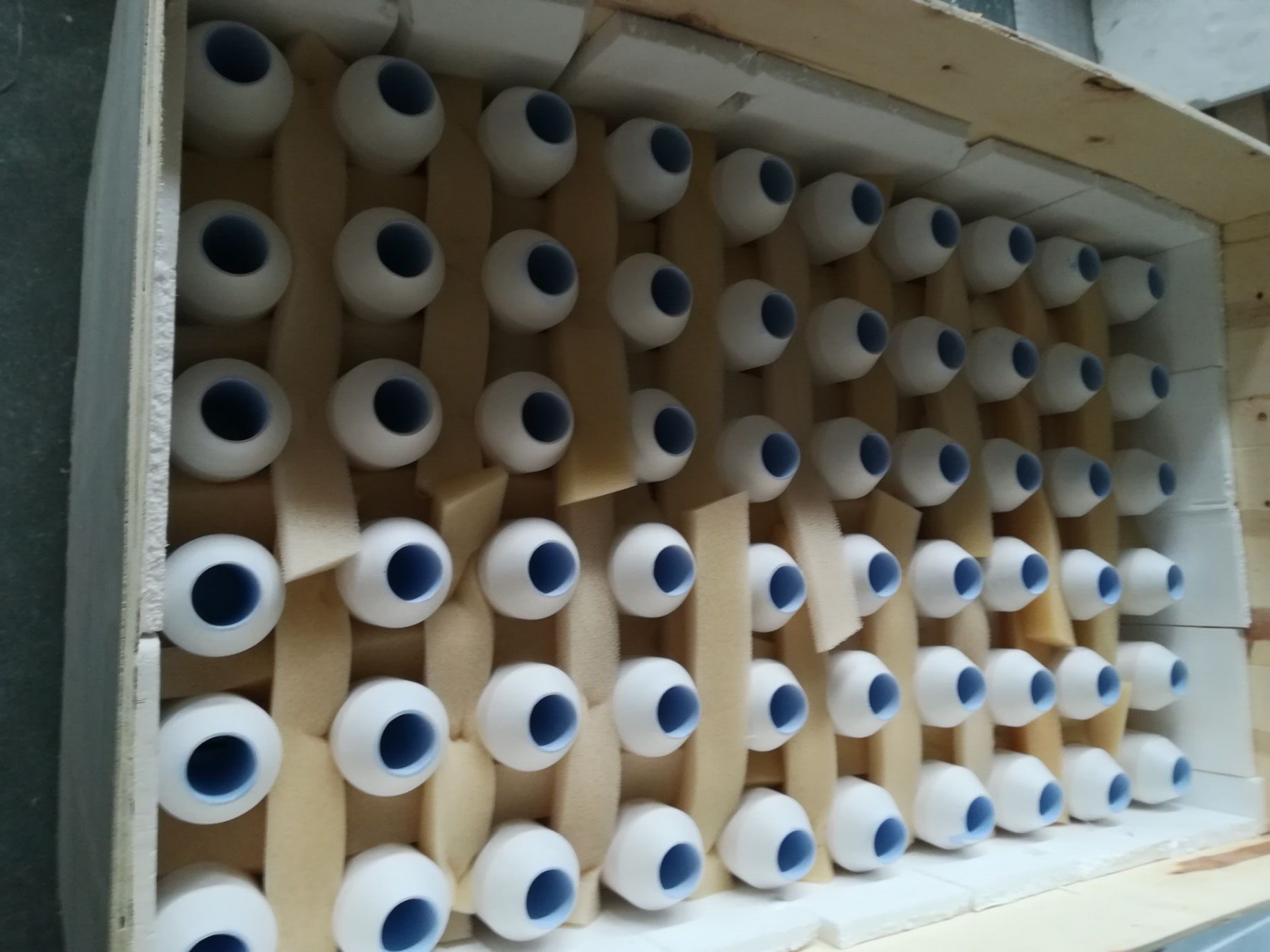

08 3月 Referactoy Ceramic Fiber Cone Tap Out Cone

Referactoy Ceramic Fiber Cone Tap Out Cone is to control the flow of molten aluminum in the launder. The aluminum silicate plug is sometimes also called heat preservation plug, heat preservation cap, Tap Out Cone, heat preservation plug of the water outlet furnace mouth. Mainly made...