15 5月 Ceramic Filter Suppliers Australia

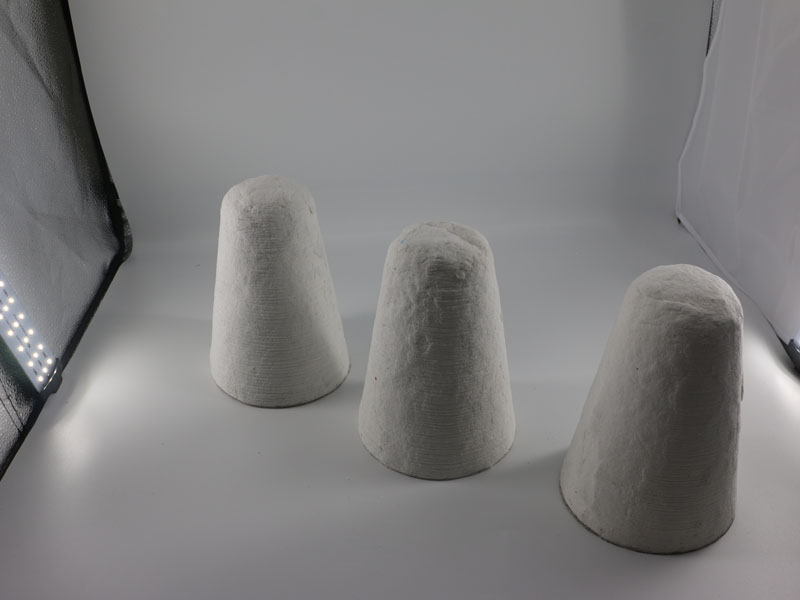

Ceramic Filter Suppliers Australia adopts the adsorption principle, which can effectively remove large inclusions in the aluminum liquid and effectively adsorb small inclusions of small size. Effectively reduce the pollution of aluminum liquid. Foam ceramic filters are no stranger to those in the aluminum casting industry. As...