03 12月 Aluminum alloy melt purification

Aluminum alloy melt purification

Aluminum alloy purification method can be divided into adsorption purification and non-adsorption according to its principle of action, two basic types. Adsorption purification refers to the direct reaction of the aluminum melt with the adsorbent (such as a gas, a liquid, a solid refining agent, and a filter medium) in contact with the adsorbent and the melt

Physical and chemical, physical or mechanical work of gases and solid oxide inclusions.

Use to achieve the purpose of degassing and removing impurities.

The flux method is to add the flux to the inside of the melt during the melting process of the aluminum alloy.

Through a series of physical and chemical effects, the purpose of degassing and removing impurities is achieved. Flux removal energy

The force is the adsorption and dissolution of the oxidized inclusions in the melt by the flux and the melting

The chemical interaction between the agent and the melt is determined. Interface between flux and inclusions

The smaller the tension, the better the adsorption of the flux and the stronger the impurity removal effect.

In addition to the flux for degassing and impurity removal, there are some other fluxes.

Such as covering agent, cleaning agent and the like. Repeated use of various fluxes, resulting in increased smelting costs, increased

Adding the possibility of introducing impurities, so the research and development cover protection, purification, deterioration, fine

The new flux, which is integrated into functions, is still one of the future development directions.

There are many kinds of Aluminum Alloy Melt Refine Flux used in Aluminum alloy melt purification, which can be divided into two types: covering agent (flux for preventing melt oxidation and inhalation) and refining agent (gas for removing gas and inclusions for inclusions). The covering agent is different from the refining agent. However, any flux used in the aluminum alloy smelting process must meet the following conditions.

1. The melting point should be lower than the melting temperature of the aluminum alloy.

2. The specific gravity should be less than the specific gravity of the aluminum alloy.

3. can adsorb and dissolve inclusions in the melt and can remove gases from the melt.

4. should not be chemically active with metals and furnace linings. If it acts with metals, it should only produce inert gases that are insoluble in metals, and the flux should be insoluble in the molten metal.

5. The hygroscopicity is small and the evaporation pressure is low.

6. should not contain or produce harmful impurities and gases.

7. should have appropriate viscosity and fluidity.

8. easy to manufacture: the price is cheap.

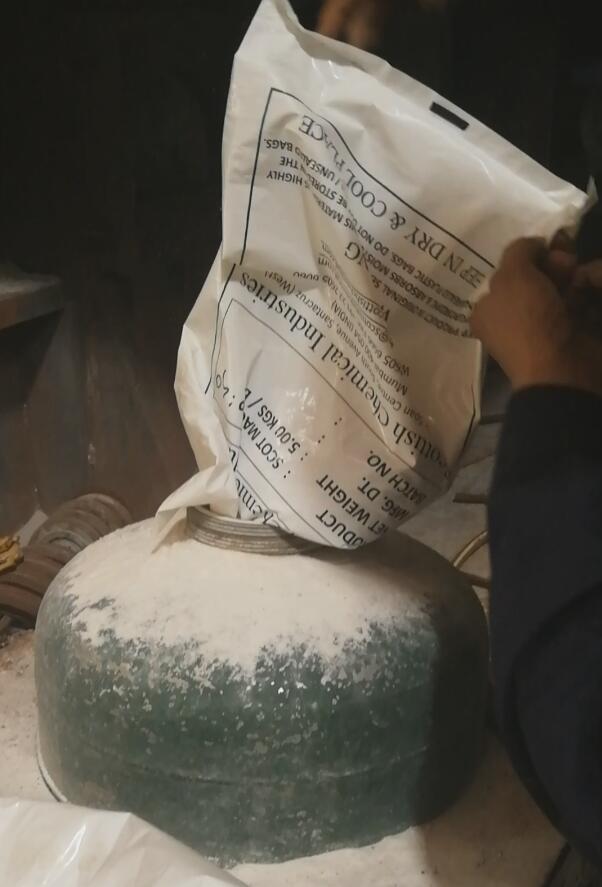

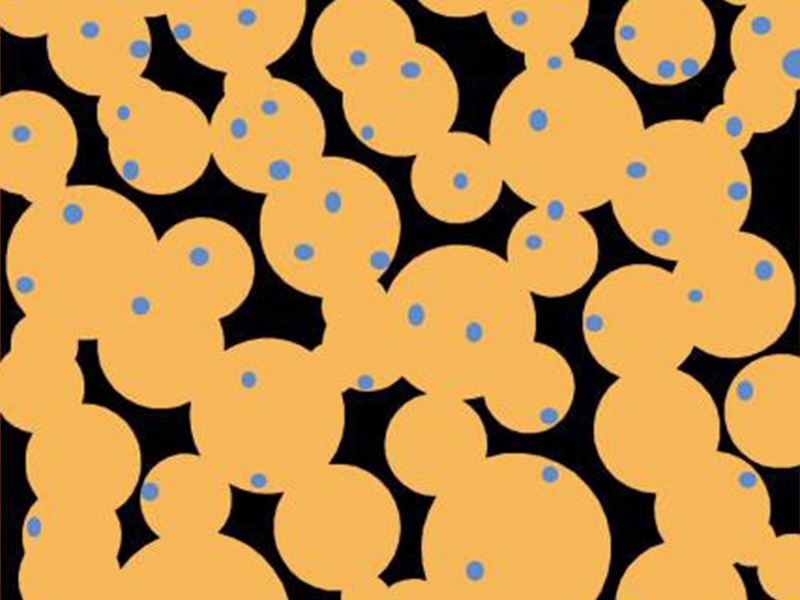

AdTech’s refining flux is white with slightly gray powdery fine particles. Main ingredients are chloride and villiaumite, together with other compounds. After appropriate heat treatment and screening, it turns to uniform size, which is conducive for transferring in refining jar with(N2 or Ar) gas as carrier to the bottom layer of molten aluminum. Through physical and chemical changes in the molten aluminum, numerous small bubbles are formed and fully contact with molten aluminum, separating hydrogen and other harmful gases. At the same time, adsorbing and fusing compounds contained in the refining flux can strongly adsorbing and fusing oxide and float, attaching together to the bubbles, with the rise of the bubbles and being brought to the surface of molten aluminum, so as to achieve the degassing and deslagging purpose of purification. Both environmentally friendly and economically, purifying with AdTech’s refining flux meets the requirement of high value-added & high-tech performance aviation, transportation and other aluminum alloy precise casting production, such as computer hard drive, micron-sized aluminum foil raw material, PS baseboard for printing, canning materials, fan blades for turbojet engine, etc.

No Comments