30 3月 Removal of impurities from refining flux

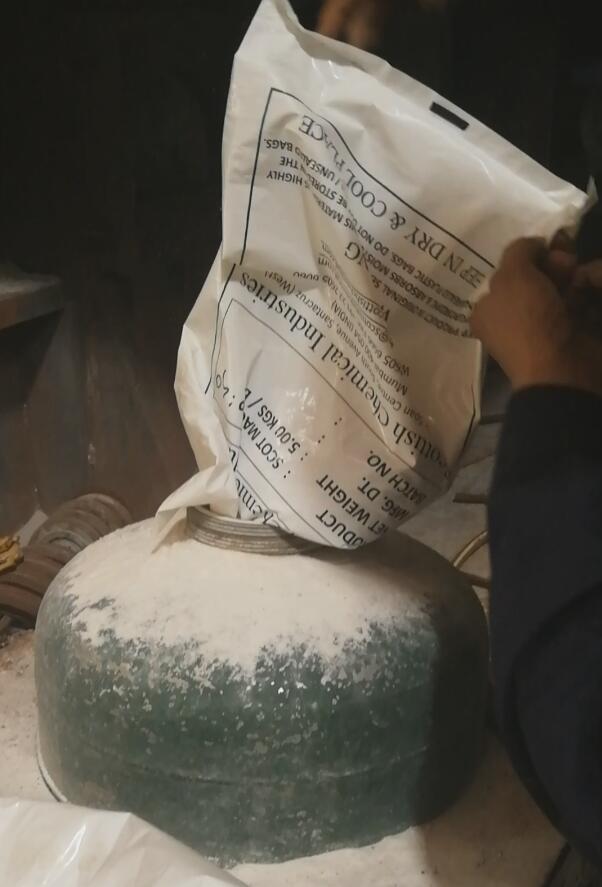

Removal of impurities from refining flux

In aluminum melts, refining fluxs can remove impurities such as metals and their oxides from the melt through physical and chemical interactions. The refining ability of the refining flux is mainly determined by the refining flux’s ability to adsorb and dissolve the oxides in the melt and the chemistry of the refining flux and impurities. The smaller the interfacial tension between the refining flux and the impurities, the better the adsorption. Some impurities in the melt, such as ferrosilicon, are difficult to remove, and these have an adverse effect on the properties of the aluminum alloy.

AdTech focuses on R&D, production and sales of aluminum refining fluxs for the degassing of molten metal during the aluminum alloy casting process and the refining flux for slag discharge. This refining flux uses unique technology to enhance the liquid metal. The effect of traditional degassing and slag removal is used in the casting and rolling process of multi-series aluminum alloy products: Micron-sized aluminum foil wool, printing PS base, can-making materials, flexible packaging materials, rail transit, aerospace products, cables Degassing and slag purity purification of molten metal during the casting of aluminum alloy raw materials such as wire ;

No Comments