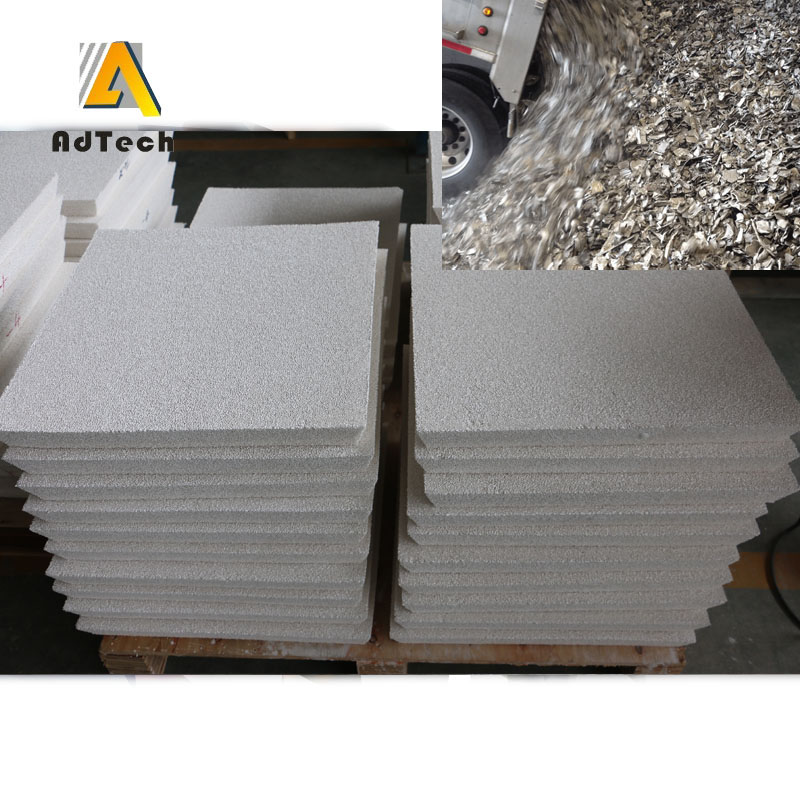

10 9月 Features of smelting aluminum alloys

Features of smelting aluminum alloys The smelting of most aluminum alloys is not difficult. Alloying components, with the exception of magnesium, zinc, and sometimes copper, are introduced in the form of ligatures. As a rule, protective fluxes are not used in the smelting of small portions of...