02 7月 Foam Cermic Filter

Foam Cermic Filter user EL Aluminium Billet(M)SDN BHD introduce the basic knowledge of aluminum water treatment.

First, transfer aluminum

Precautions for putting aluminum water: 1. Make sure the hook of the transport bag is hung 2. Before putting water, you must wear labor insurance 3. Stand on the pedal to operate

Process requirements

1. Scoop out the aluminum slag on the surface of the sink

2. Close the notch cover

Second, dusting

Powder spraying frequency: powder spraying once per pack of high-temperature furnace; powder spraying once per shift in low-position furnace. The specific powder dosage is 2 packs at a time (2Kg per pack, a total of 4Kg)

Process requirements

1. Connect with nitrogen and control the pressure at about 0.2MPa.

2. When spraying powder, continuously move the spraying tube.

3. The powder spraying tube cannot be inserted into the bottom of the furnace, so as not to be blocked and unusable

4. After the spraying is completed, the powder spraying tube should be taken out before turning off the nitrogen.

5. Powder spraying time is required to reach about 3 minutes

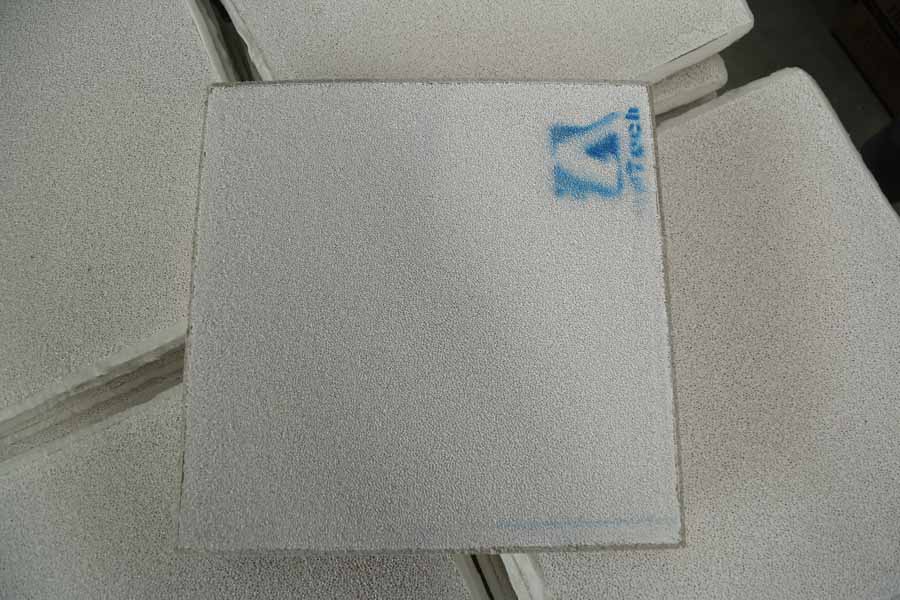

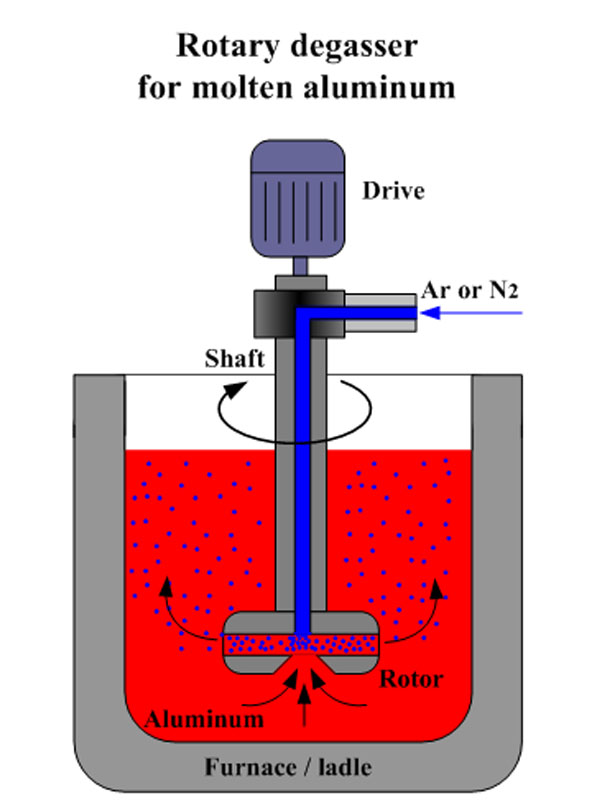

Filtration

1. Check and clean the debris on the surface of the filter box to keep the filter box clean and free of damage;

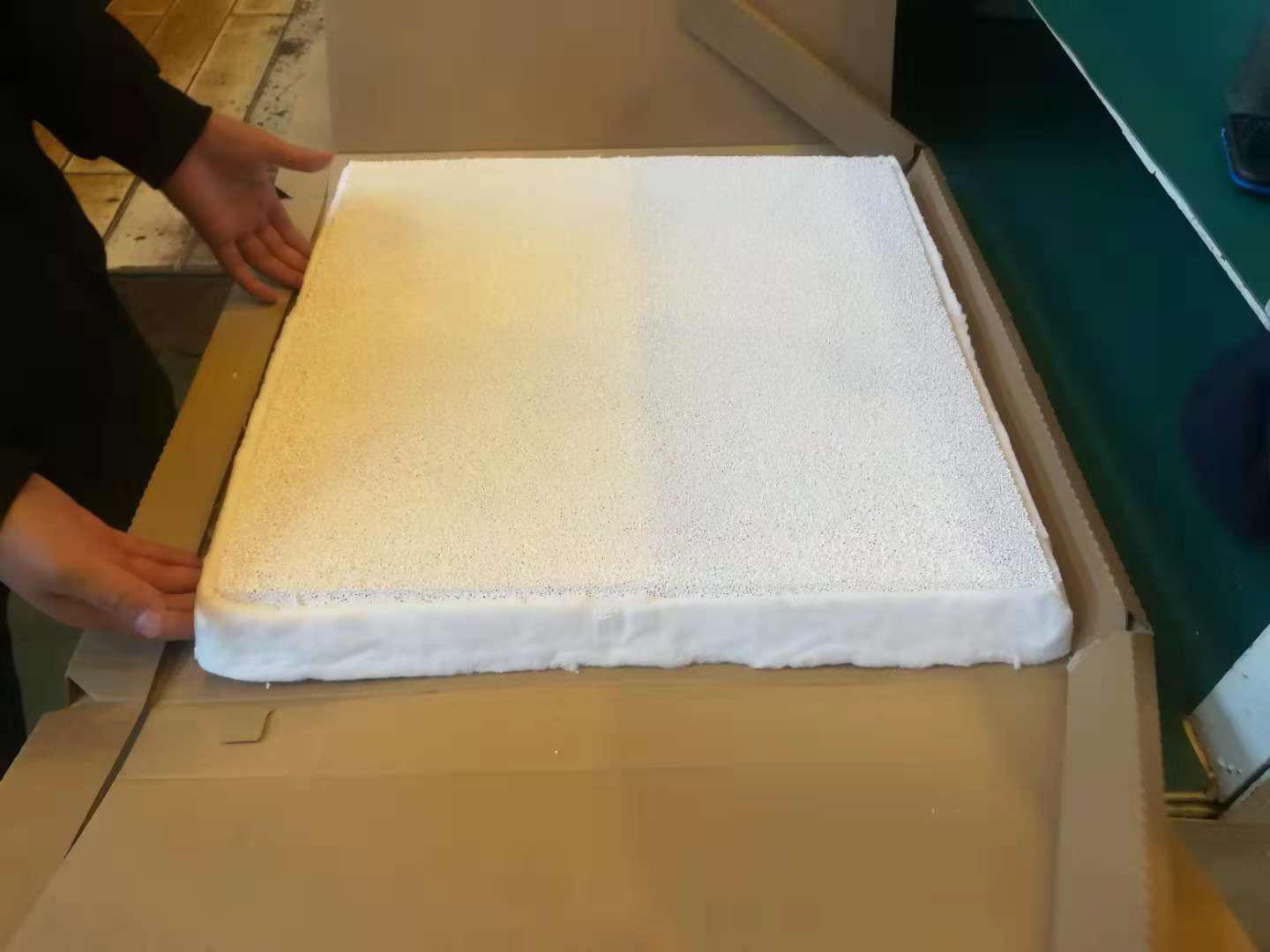

2. Gently put the Foam Cermic Filter into the filter box and press the sealing gasket around the Foam Cermic Filter to prevent the aluminum liquid from flowing or floating;

3. Evenly preheat the filter box and the filter plate to make it close to the temperature of the aluminum liquid. The preheat temperature of the filter plate is not less than 460 ℃. The expansion cotton automatically seals the edge when heated. The filter plate is not easy to float and preheat to remove the adsorbed water Servings.

4. Observe the changes of the aluminum hydraulic head during casting to maintain the control flow of the normal demand aluminum liquid. The normal starting head is 100-150mm. When the molten aluminum begins to pass,

The indenter will fall below 75-100mm, and then the indenter will gradually increase;

5. During normal filtration, avoid knocking and shaking the filter plate. At the same time, the launder should be filled with aluminum liquid to avoid the disturbance of too large or too small aluminum liquid;

6. After filtering, remove the filter plate in time and clean the filter box.

EL Aluminium Billet buy Foam Cermic Filter and the flux from adtech China through sales@adtechamm.com

Three, add magnesium block

Magnesium ingot addition time: add one piece in half an hourAddition method: add to degassing chamber, use a ladle to press in aluminum water to melt

Four, strontium change

Add frequency and dosage: add 5-6 strontium rods to the degassing chamber every half hour

Matters needing attention: It is strictly forbidden to directly enter the aluminum water, and the aluminum water should be gently put in order to prevent the aluminum liquid splashing from generating oxide scales, even hurting people.

Five. Cleaning residue

Frequency and dosage: Clean the slag once every half hour, first clean the water intake, then scoop it to the refining room and stir-fry, 1 packet (one kilogram) per dosage.

Precautions

1. It is strictly forbidden to throw the slag remover directly into aluminum water, open the plastic bag and pour it into aluminum water

2. When frying the slag, the action should not be too large, so as to avoid the generation of oxide scale from the aluminum liquid

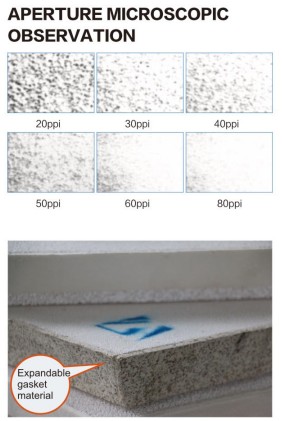

Six, hydrogen measurement

Nitrogen parameter control: purity requirements above 99.995%, pressure requirements above 0.2MPa; nitrogen flow requirements between 1.5~2.5m3/h; hydrogen measuring instrument parameter setting: time relay setting time 240S, hydrogen measuring pressure requirement -0.095MPa The following hydrogen measurement frequency: once every hour; check the sample block: refer to the sealed sample to determine whether it is qualified. If the hydrogen measurement is not qualified, check whether the nitrogen parameters meet the process requirements, and do the processing, can not handle the situation.

Sorry, the comment form is closed at this time.