26 2月 Flux In Metallurgy for Aluminum

Flux In Metallurgy for Aluminum

Flux In Metallurgy Product principle:

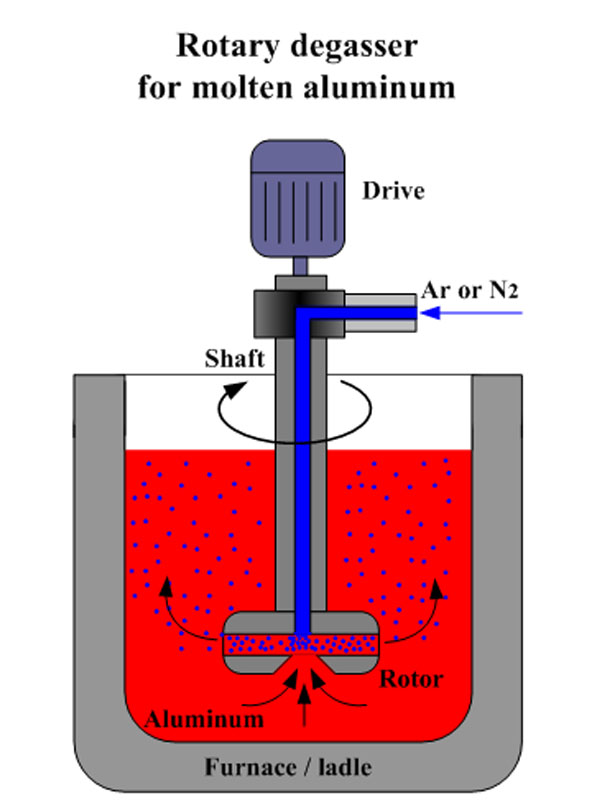

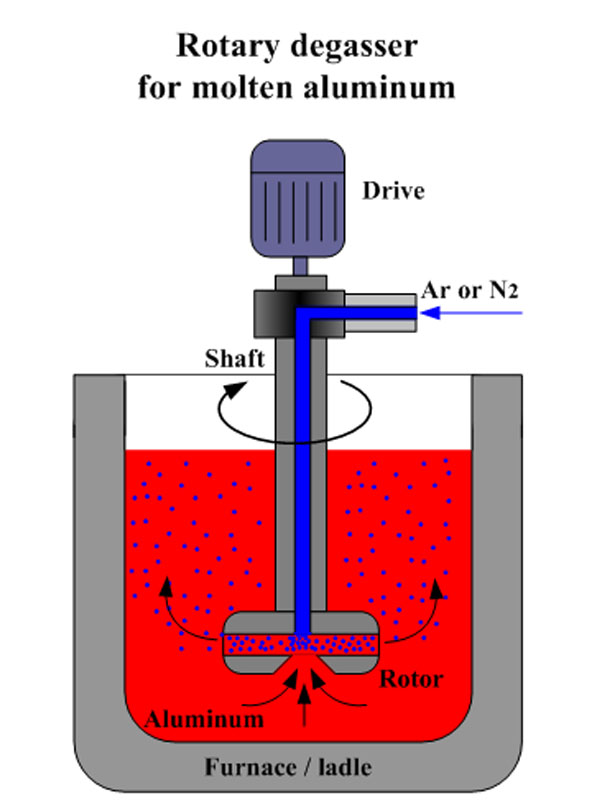

by use of a powder spraying machine, spray powder refining flux into an aluminium melt bath with high-purity nitrogen. under the combined effect of dispersed tiny nitrogen bubbles and flux, it will eliminate the entrapped slag and hydrogen in aluminium liquid.

Main features:

1. High efficiency, 100% efficient composition.

2. Strong purifying capacity up to domestic advanced level.

3. Less pollution, small consumption and low cost.

Use method:

Adding refining flux of the required amount into the refining tank and covering it properly, turning on the switch of the refining tank and connecting nitrogen gas. When refining flux is spraying out of the refining iron tube, insert it into the furnace and move it all around inside evenly 2 or 3 times. When powder inside the tank is sprayed completely, first draw the refining tube out of aluminium liquid, and then switch off nitrogen gas.

Technical parameters:

1. Refining temperature: 700℃~740℃.

2. Refining time: 8~15 minutes (6~20ton furnace).

3. Use level 1~3kg for one ton aluminium.

Precaution:

1. the refining time shall be extended along with the increase of aluminium malting volume.

2. the powder feeding rate can be controlled by adjusting the switch on the bottom of the refining tank. Generally, there should be powder spraying out within the range of refining time.

3. the end of the refining tube should be inserted into the furnace by 2/3 of the aluminium liquid depth. 4. the tube shall be moved to the left and right side. the furnace wall and bottom shall not be touched to prevent clogging of the tube.

5. the turbulence height of aluminium liquid shall be controlled by nitrogen pressure.

Packaging and Storage:

It is 2kg for each package and 20kg for each box, which shall be stored in a day and ventilated place. the storage period is one year if plastic bags are not damaged. It can be further used when it is ground into powder and dried at the temperature of 100℃.

No Comments