07 12月 Filter Bowl

Filter Bowl

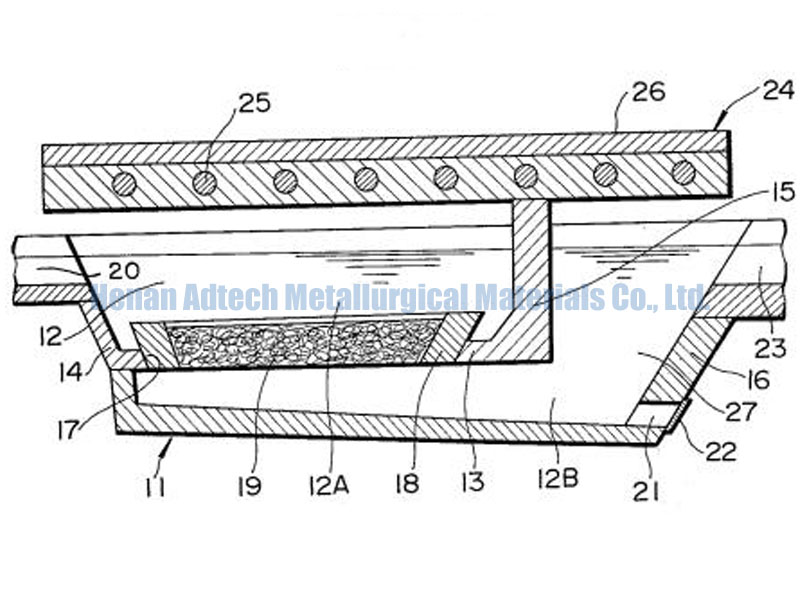

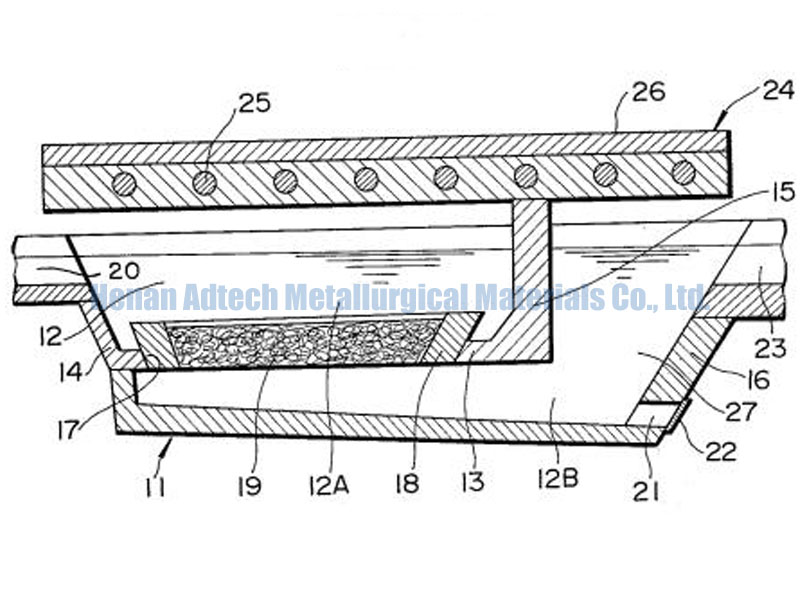

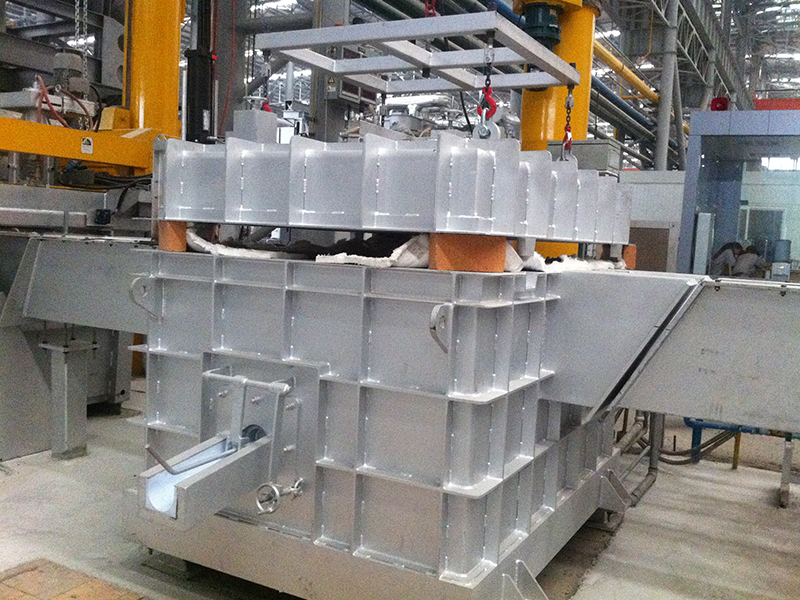

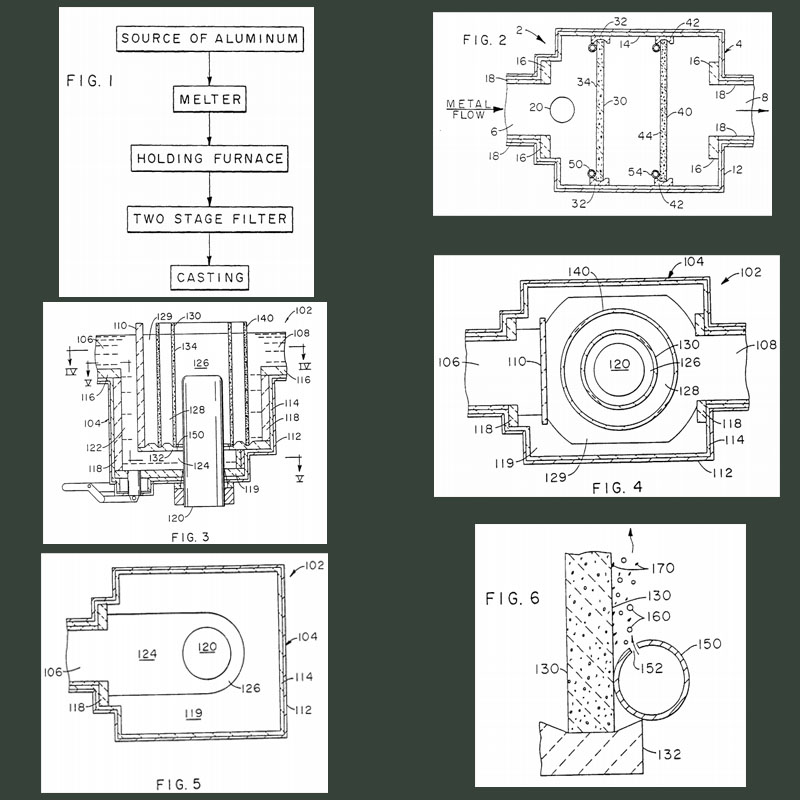

1. A Filter Bowl for a molten metal comprising:

A Filter Bowl provided in a flow path for molten metal;

A horizontal partition disposed within said filter housing and having at least one filter frame-setting hole therethrough;

A filter frame detachably fitted to said filter frame-setting hole, including a filter medium-receiving hole therethrough and including an upper portion which protrudes from said filter frame-setting hole to provide a holding means for being grasped to permit easy removal and replacement of said filter frame; and

A filter medium in the shape of a substantially flat plate positioned within said filter medium-receiving hole of said filter frame at a level such that the upper surface of said filter medium is below said holding means defined by the protruding upper portion of said filter frame and is below an inflow path and an overflow path of said molten metal for maintaining said filter medium and filter frame immersed in molten metal when said filtering device is not in operation, and wherein said filter medium immersed in molten metal is exchanged by grasping said holding means and removing and replacing said filter frame and filter medium without removing molten metal from said filter housing.

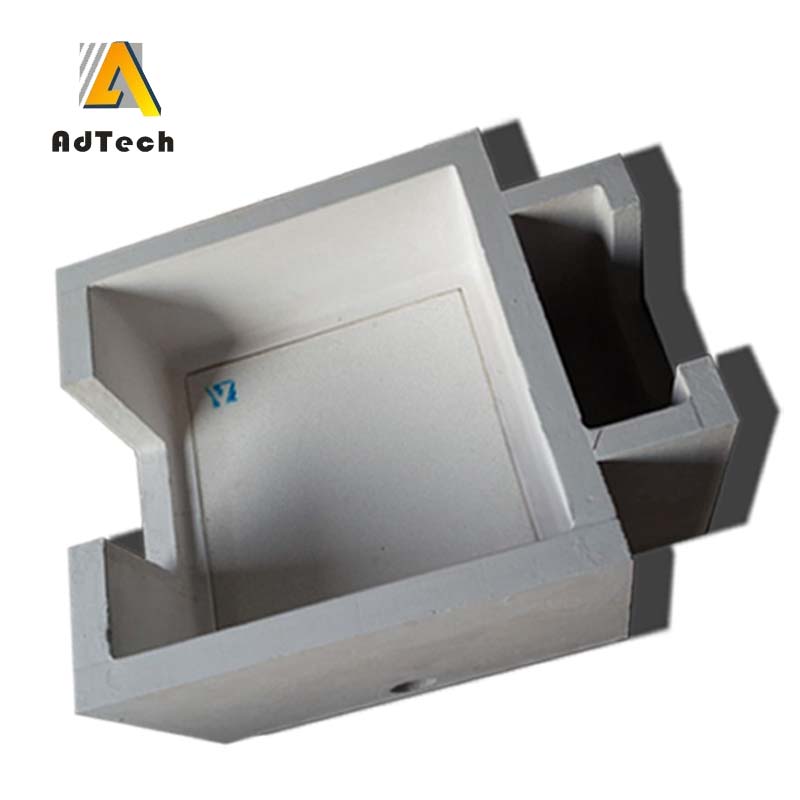

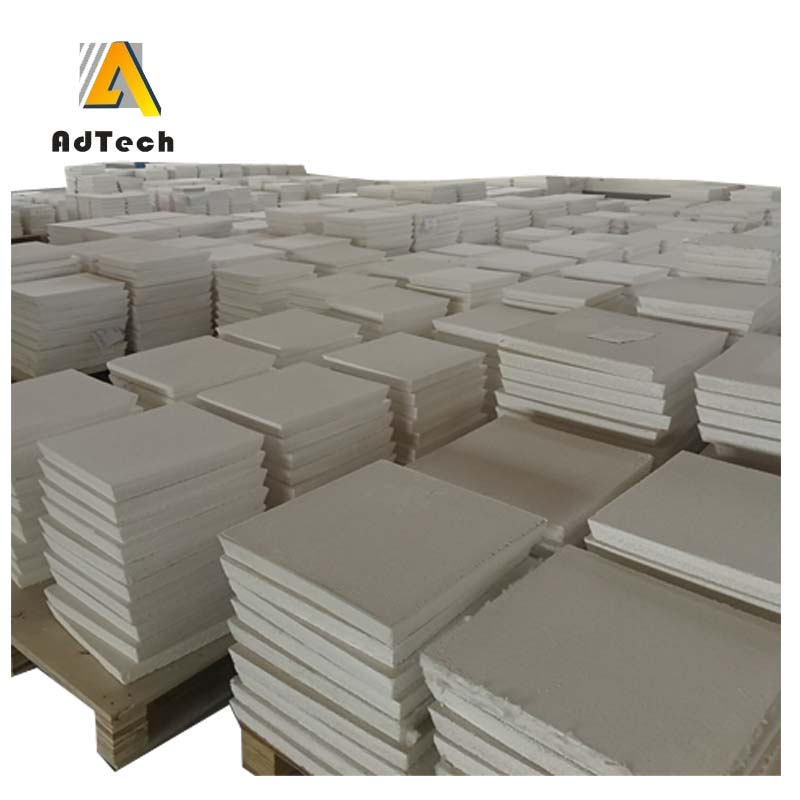

2. The Filter Bowl according to claim 1, wherein the filter medium is formed of a porous ceramic material.

3. Filter Bowl according to claim 2, wherein the porous ceramic material is a ceramic foam obtained by coating a flexible polyurethane foam having a substantially skeletal reticulated structure with a ceramic slurry and sintering the foam coated with the ceramic slurry to remove the foam and leave the ceramic strands.

4. A Filter Bowl as in claim 1, wherein said filter housing further includes a cover means having a plurality of heat generating means integral therewith.

5. A Filter Bowl for a molten metal comprising:

A filter housing provided in a flow path for molten metal;

A horizontal partition disposed within said filter housing and having at least one filter frame-setting hole therethrough;

A filter frame detachably fitted in said filter frame-setting hole, including a filter medium-receiving hole therethrough and including an upper part thereof which protrudes from said filter frame-setting hole to provide a holding means for being grasped to permit ready removal and replacement of said filter frame;

A filter medium in the shape of a substantially flat plate formed of a porous ceramic material positioned within said filter medium-receiving hole of said filter frame at a level such that the upper surface of said filter medium is below said holding means defined by the protruding upper part of said filter frame and is below an inflow path and an overflow path for said molten metal for maintaining said filter medium and filter frame immersed in molten metal when said filtering device is not in operation, wherein said filter medium immersed in molten metal is exchanged by grasping said holding means and removing and replacing said filter frame and filter medium without removing molten metal from said filter housing; and heat generating means provided above said filter housing and supplying more heat than is radiated from the molten metal in said filter housing whereby the temperature of the molten metal in the filter housing does not drop while the filtering device is switched from the molten metal flow path of one smelting furnace to another metal flow path of another smelting furnace.

6. The filtering device according to claim 5, wherein the porous ceramic material is a ceramic foam obtained by coating a flexible polyurethane foam having a substantially skeletal reticulated structure with a ceramic slurry and sintering the foam coated with the ceramic slurry to remove the foam and leave the ceramic strands.

No Comments