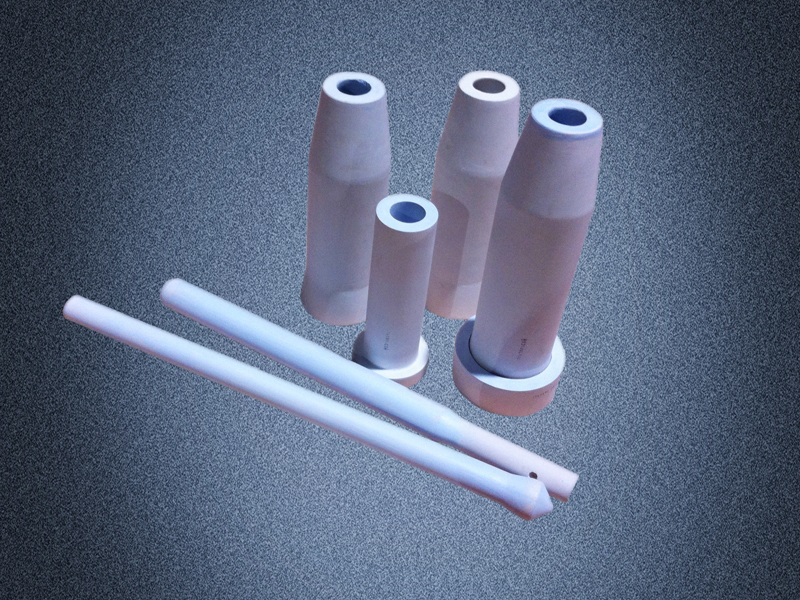

05 3月 Ladle Shrouds Long Nozzles

Ladle Shrouds Long Nozzles have good drainage and heat preservation effects, and the aluminum melt can flow smoothly and safely to the casting platform, so that the aluminum liquid casting with different liquid levels cannot be completed. Ladle Shrouds Long Nozzles control device, including lifting shaft...