05 3月 Long Stoppers

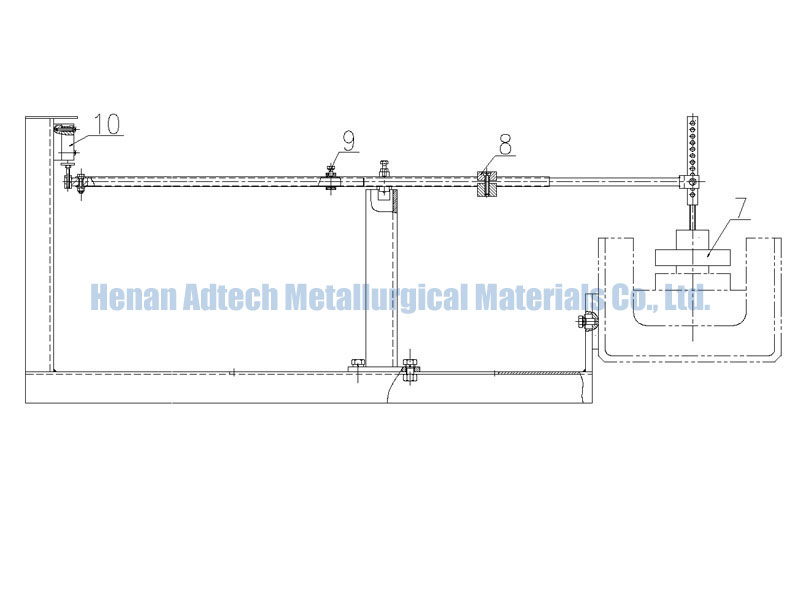

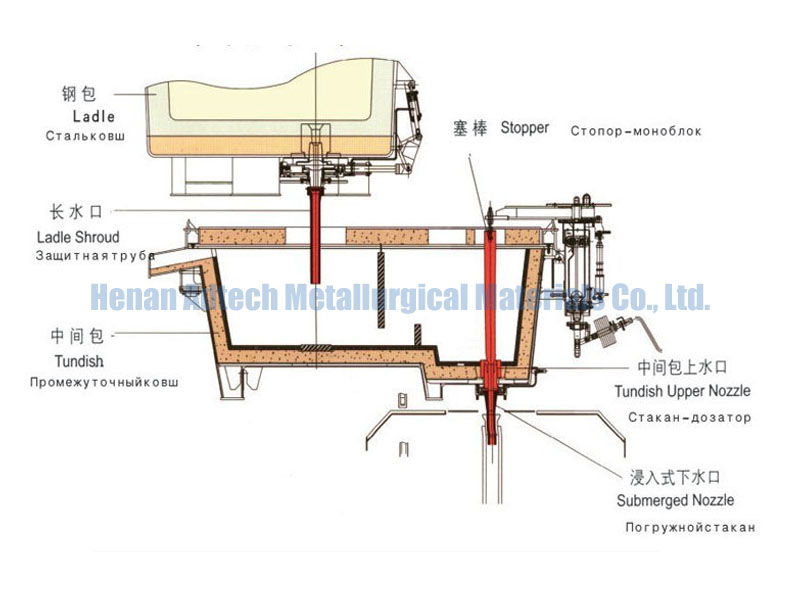

Long Stoppers can control the flow of aluminum melt through the high-level flow trough to the insulation pipe, and then smoothly divert to the low-level flow trough, splitter plate or transfer duct. Its main function is to solve the problem of height difference in the casting process.

Long Stoppers can adjust the distribution flow of aluminum water in the two-stage flow trough by controlling the size of the gap between the stopper rod and the orifice.

For example, in slab casting, it can be used in any place where there is a difference in the level of aluminum water level, such as a launder, and the flow needs to be controlled.

At present, in casting enterprises, the molten metal is often transferred from melting to pouring. Especially in the production of aluminum alloys, due to the active nature of aluminum alloys, effective protection of the molten aluminum is particularly important.

In aluminum alloy continuous production enterprises, the aluminum ingots must be transferred to the pouring and holding furnace after the melting furnace is qualified for refining and deterioration.

At present, most companies use subcontracting to transfer directly, and some use subcontracting to pour into the open diversion groove through the diversion groove to naturally flow into the holding furnace, so that the flow of aluminum liquid is relatively turbulent, and it flows in the air, which inevitably produces inhalation and Slagging.

The commonly used method of inverting the furnace is the flow tube method. The flow tube inversion method is a method in which the liquid enters the static furnace through the flow hole, along the flow channel, and the flow tube according to the static pressure of the liquid produced by the drop between the smelting furnace and the static furnace.

In this process, sulfur powder or flux should be used to protect the surface of the liquid, and the metal should flow in the full pipe so that the melt in the launder can flow smoothly.

In addition, converter methods include siphon converter method, nitrogen-charged boost converter method, magnetic pump and centrifugal pump converter method.

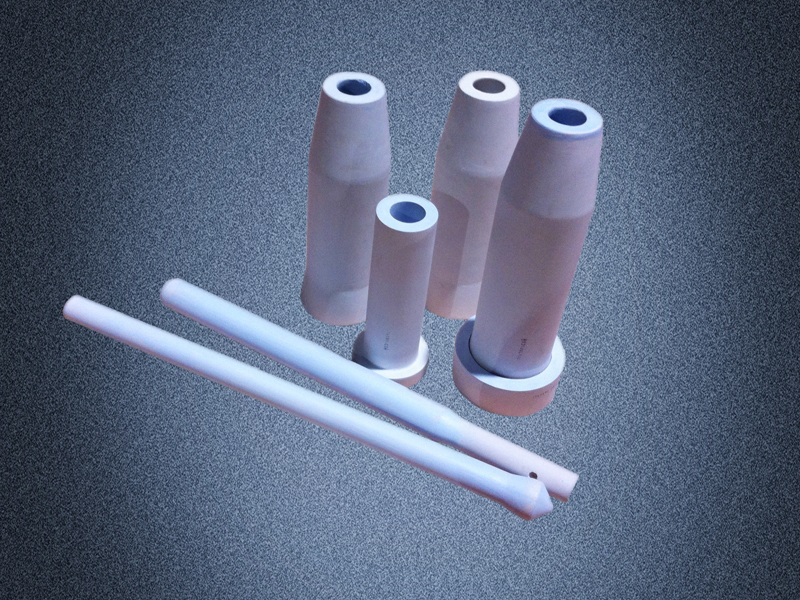

Long Stoppers are all formed by isostatic pressing, and their shape and size depend on the capacity of the tundish, the height of the molten aluminum, and the shape of the horn of the tundish nozzle and the size of the aperture.

The stopper rod has an integral stopper rod with a hollow, argon blowing hole or a breathable plug.

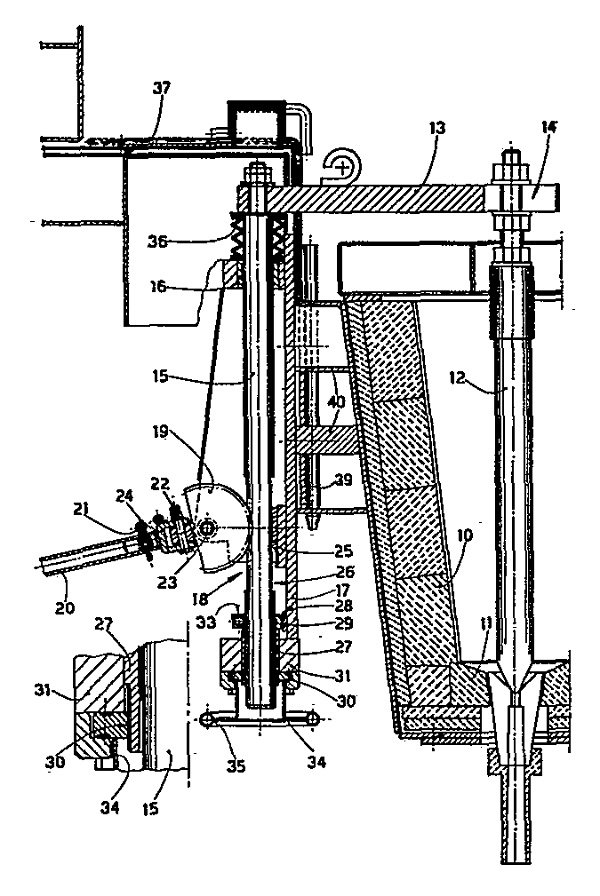

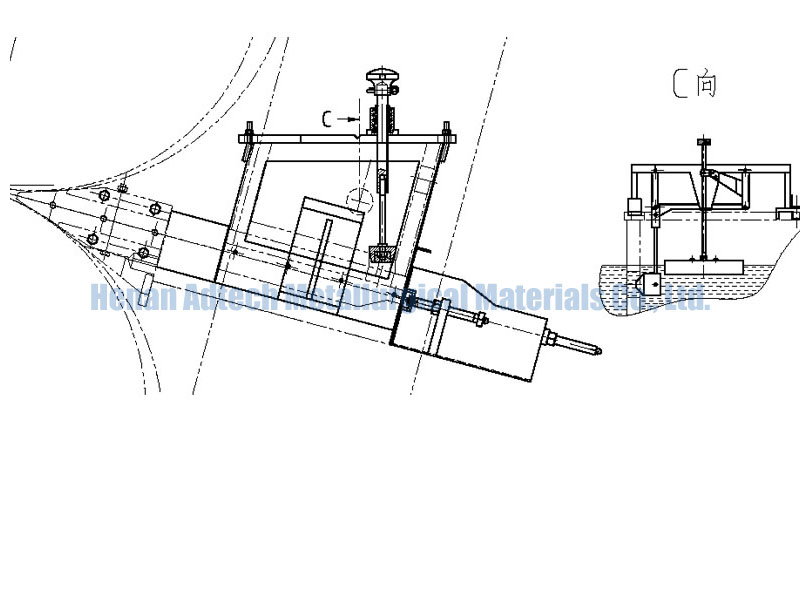

The tundish stopper rod control system of the continuous casting machine is used in the stable constant drawing speed casting of the mold liquid level in the metallurgical continuous casting machine.

It is an integrated stopper rod execution system, which uses a closed box and consists of a servo motor system, an actuator, a sensor, a computer, etc., and its system has high precision, is not affected by the environment, and has accurate transmission without gaps. , No time difference, simple and convenient tundish stopper control system.

No Comments