15 11月 Foam Ceramic filters

Foam Ceramic filters

The main working principle of Foam Ceramic filters is to make the chaotic, torn metal liquid pass through the foam ceramic honeycomb hole and become a smooth, uniform, and clean metal liquid.

The unique honeycomb structure can adsorb some small particle impurities in aluminium water, such as non-metal particles, slag, refractory fragments, etc., into the filter.

Secondly, the smooth metal laminar flow fills the model better, on the one hand, overflowing the gas, on the other hand, reducing the erosion of the model and reducing the product scrap rate.

It can improve the metallographic structure and mechanical properties of castings, produce high-quality standard precision castings, reduce the scrap rate of castings, reduce the wear of cutting tools during casting processing, and increase the economic and social benefits.

The specific functions and characteristics of Foam Ceramic filters

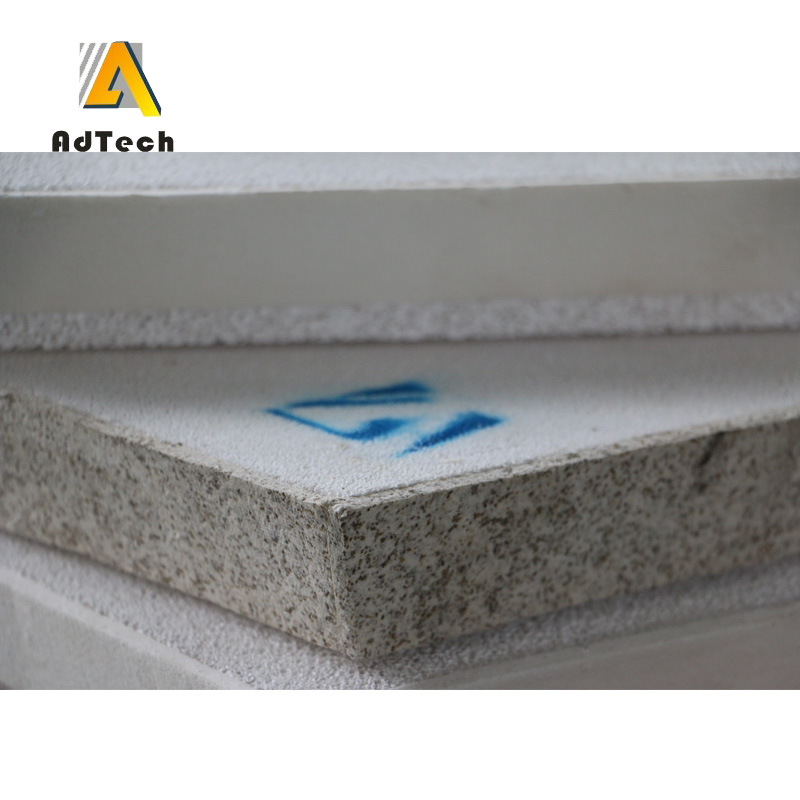

1. The honeycomb structure can adsorb particles filter the inclusions in the casting, and escape the bubbles contained in the molten metal, effectively reduce the internal and external pores of the casting, reduce surface defects, reduce the filling turbulence during casting, and significantly improve the casting yield. This is superior to high silica mesh screens and straight-hole filtration products. The former is for sieving and adsorption of tiny slag, while the latter two are only for sieving.

2. Let the molten metal change from eddy current to stable flow and stabilize the purified metal liquid. It not only uniforms the metal liquid, but also increases the compression sealing of the casting, further enhances the casting elongation (about 25%) and tensile strength, and the surface finish is relatively improved.

3. Simplify the design requirements of the casting system, reduce the length of the runner, and improve the production rate of the casting process.

4. The inside of the casting is clean, which reduces the machining time and tool damage of the casting, and the production efficiency is improved.

Foam Ceramic filter recommendations

1. Control the melting point of the alloy by using a molten aluminium filter. To avoid excessive temperature, damage the filter function.

2. choose the appropriate aperture, the purification effect should match the casting requirements.

3. The casting temperature should be as high as possible to increase the metal fluidity.

4. When the filter is placed horizontally under the intersection cup or on the parting surface, the casting height should not exceed 20 cm. It is best to flush the metal liquid on the wall of the intersection, and do not directly rush to the filter to avoid damage to the filter.

5. the filter is placed gently and gently. When not in use, put it in a dry and ventilated place. Use an air gun first to ensure that there is no debris in the filter.

Sorry, the comment form is closed at this time.