07 11月 Aluminium Ceramic Foam Filter

Aluminium Ceramic Foam Filter

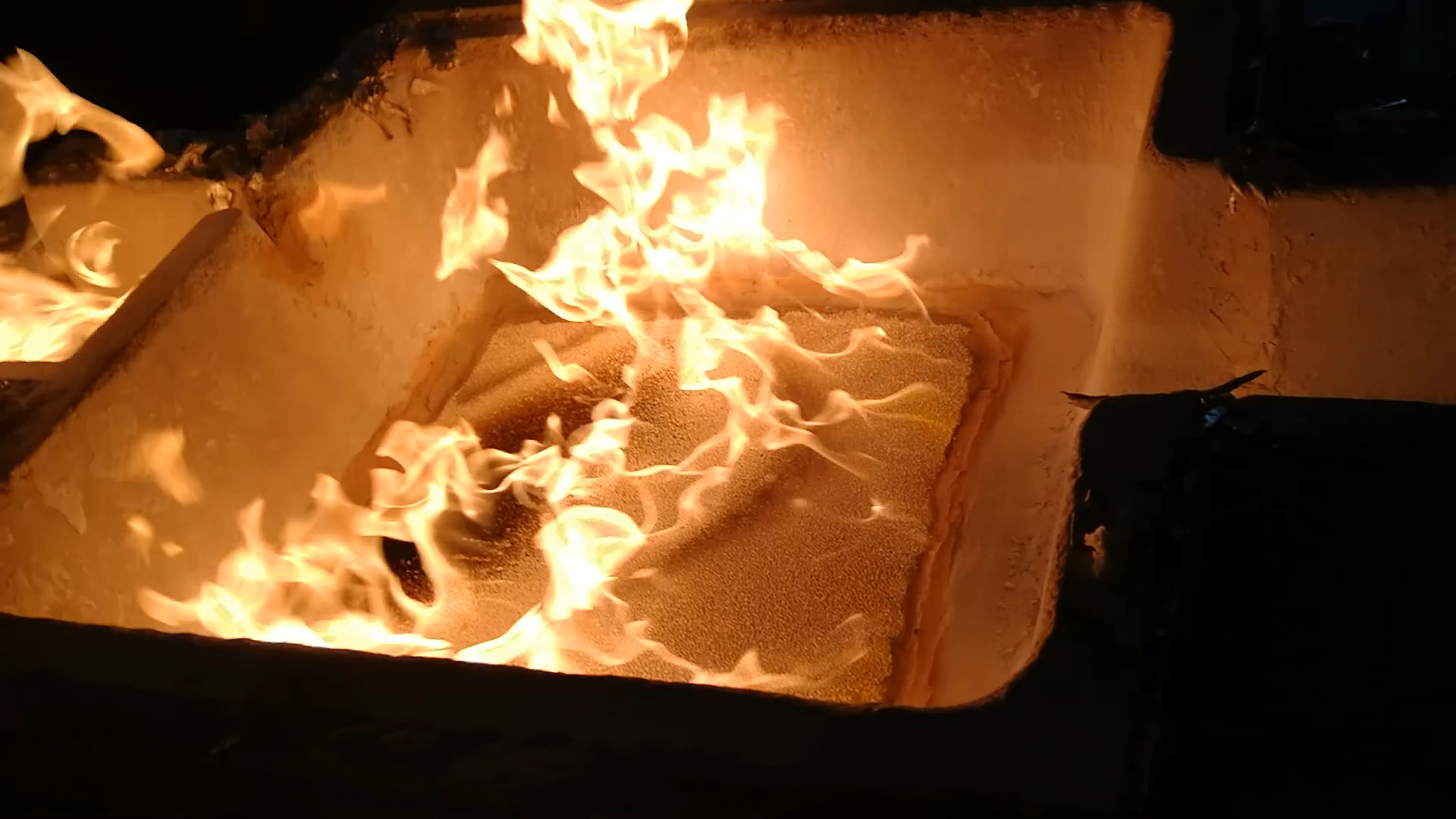

Ceramic Foam Filtration (CFF) System employs dedicated Aluminium Ceramic Foam Filter to remove inclusions which are generated between the refining system and the mold table. The ability of the ceramic foam filter to capture these inclusions is critical to maintaining a clean ingot during the solidification of metal. Accordingly, the quality and the productivity in downstream operations such as forging, extruding, and rolling are guaranteed.

At Adtech, the continual quest is to ensure that our customers receive the best technology available on the market to produce the highest quality billet, slab, or ingot for their customers. Our guarantee does not stop with our customer, but continues to our customer’s customer! Our technology guarantees conformance of casting quality for the most critical end-product applications.

Keywords=Aluminium Ceramic Foam Filter,Ceramic Foam Filte,Ceramic Filter Plate,Porous Aluminum plate,Silicon Carbide Ceramic Foam Filter,Alumina Ceramic Filter,Alumina Foam Filters,Molten Metal Filtration,Cast House Filter,casting filter.

Why Aluminium Ceramic Foam Filter?

Filtration with ceramic foam filters offers several key benefits that improve the quality of premium aluminum castings. These include:

Improved mechanical properties

Reduced dye-penetrant indications

Reduced x-ray evidence of nonmetallics

Reduced rework/scrap;

Improved machining properties.

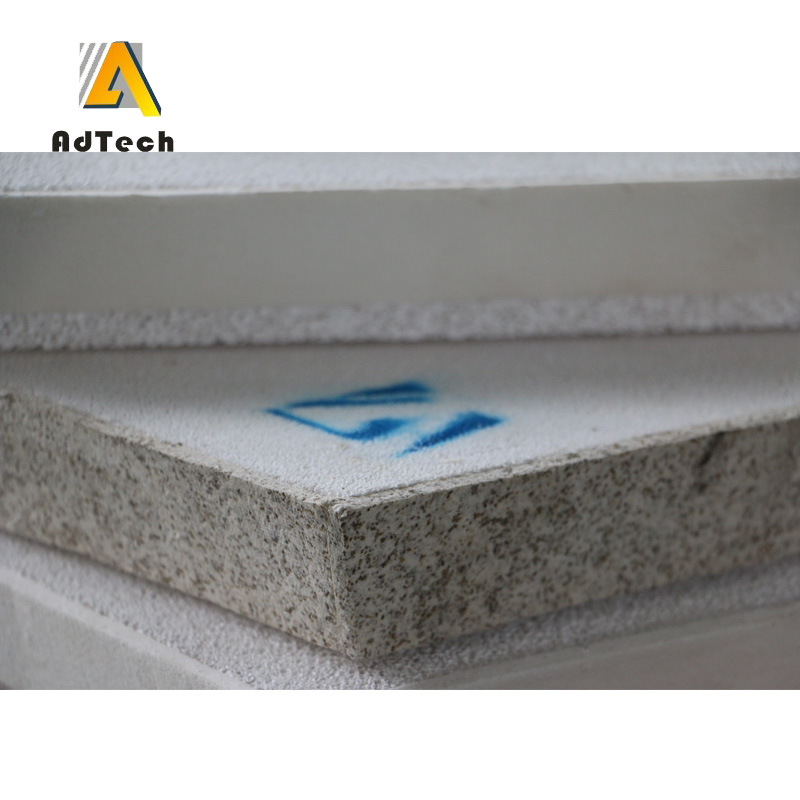

Aluminium Ceramic Foam Filter from AdTech Metallurgical Materials Co., Ltd has been focusing on research, development, production and marketing of the adhesive ceramic foam filter(CFF) for aluminum alloy casting Since 2012.

Advantages for Aluminium Ceramic Foam Filter

Adopt adsorption principle for filter, can effectively remove big piece inclusions in molten aluminum, and effectively adsorb tiny inclusions.

No broken bits drop out, effectively reduce the pollution of molten aluminum.

Superior thermal shock resistance, improve erosion resistance ability of molten metal.

Automatic flow production,3 calibration procedures,precision size,fit the filter bowl tightly.

Improve the surface appearance and performance, purify molten aluminum.

No Comments