08 10月 Different aluminum purifying methods

Description of different aluminum purifying methods

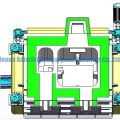

There are many aluminum purifying methods outside the aluminum melting furnace. According to their main functions, they can be divided into degassing, such as the Air-Liquid method; slag removal, such as glass fiber cloth, ceramic foam filters, and foam ceramic filtration method; degassing and slag removal. Both, such as AlcOA469, FILD, SNIF, AlPur, MINT, RDU, GBF, and so on.

Wait. After decades of development, there have been many patented products for online rotary injection purification processes abroad, such as the SNIF method of the United Carbide Company of the United States, the ALPUR method of the French Pisigne Company, the RDU method of the British Foseco Company, The GBF method of Foseco Japan, the RID method of Hitchcock of the United States, the series equipment of the rotary jet flux method developed by Pyroteck of Australia, the ALUDEF (aluminum degassing and filtration) developed by the Process Research Department of Alumina, etc.

Based on the introduction of some foreign advanced purification technologies and equipment, domestic research on aluminum alloy melt purification technology has been carried out. For example, the Dalian University of Technology and East China Aluminum Processing Factory designed and developed DUT-89 aluminum liquid purification equipment, Southwest Aluminum Processing Factory developed DFU after digesting and absorbing MINT technology, Zhuoshen Company developed CQ500 refining device based on digesting and absorbing AIJPuR, etc. Wait. Since 2001, Mattxin Company has established a comprehensive research and application team of aluminum melt processing technology relying on colleges and universities. The online degassing purification technology of the melt has been studied by simulation experiments and compared with the practical application parameters, and some achievements have been obtained.

No Comments