22 10月 Professional Foundry Foam Filter

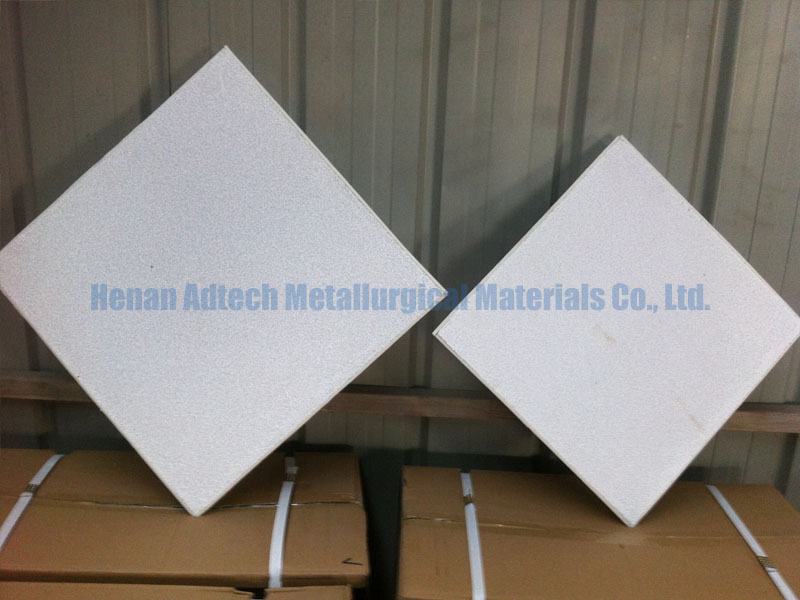

Professional Foundry Foam Filter

Professional Foundry Foam Filter is obtained from different types of ceramics – corundum, aluminosilicate, mullite, carbide.

So, silicate-bonded silicon carbide filters are used to filter cast iron.

Such filters have high strength due to the fact that during firing, SiC grains in the ceramic mass are partially oxidized to silica glass, which provides good bonding of silicon carbide with a matrix of silicate binder, creating a strong foam. However, when cast iron is cast, liquid slag with a high FeO content is formed, which does not wet the silicon carbide filters due to the carbothermic reaction between the carbon component of SiC grains and impurities of graphite, which causes the slag to adhere to the filter.

It is obvious that the selection of the optimal firing regime is essential in the production of ceramic materials, since it is at this stage that the strength of the finished product increases.

Among the phenomena occurring during firing, the most important is the sintering process, which causes the transformation of porous preforms from a conglomerate of loosely coupled particles, united mainly by the forces of friction and adhesion, into a solid body with a given structure and properties.

During sintering, the formation and growth of contacts between particles of the solid phase, a decrease in pore size and their number, up to their complete disappearance, and recrystallization shift of the boundaries between crystals take place.

At the same time, in the production process of highly porous open-cell ceramic products, it is very important to achieve, on the one hand, preservation in the finished material of the pore structure of the original PPU-frames, and on the other hand, a set of strength due to sintering of particles located in the intercellular partitions.

Ceramic Filter Suppliers from China, please contact sales@adtechamm.com

The most common way to obtain Professional Foundry Foam Filter is the technology of removing the foam replica: highly porous polyurethane foam is impregnated with a ceramic slip, after which it is dried and fired.

During firing, the polyurethane foam inside the ceramic coating evaporates and a ceramic structure with a large number of pores remains.

The preparation of oxide foam ceramics is based on the impregnation of highly porous polyurethane foam (PUF) frames with slip suspensions based on alumina powder with sintering additives, followed by firing of the impregnated frames at temperatures of about 1700–1850 ° С.

The main requirements for ceramic filters in addition to high heat resistance and chemical resistance to metal melts are the presence of open porosity at the level of 80–90% with a predominance of interconnected cellular pores and compressive strength of at least 0.5 MPa.

Filters based on oxide ceramics provide effective removal of unwanted impurities, especially inclusions of a similar composition – oxide films and slags.

Due to its high stability, even with prolonged exposure to high temperatures, oxide ceramic filters can be successfully used in filtration boxes or in heating furnaces for filtering large volumes of liquid metal.

Ceramic alumina-based cellular foams, combining high heat resistance, chemical resistance to metal melts and slags, as well as low cost of raw materials, are used as catalyst carriers and ceramic filters for metal melts.

Sorry, the comment form is closed at this time.