24 7月 Ziroconia Filter

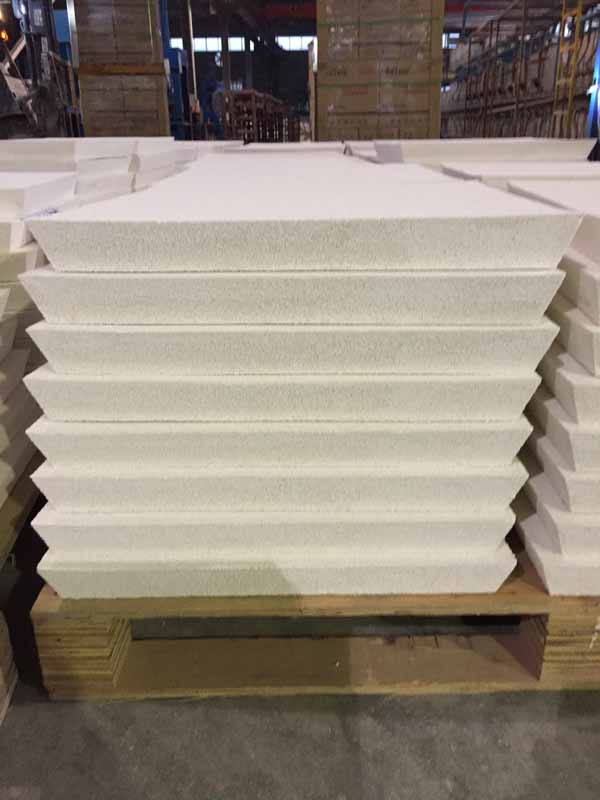

Ziroconia Filter Ziroconia Filter has been widely used in the aluminum processing industry. There are two main modes in the application of deformed aluminum alloy melt purification technology. In-furnace fluxing and refining, semi-continuous casting of foamed ceramic plate filtration outside the furnace, ceramic filter plate replacement is...