24 3月 Sodium Free Granular Flux

Sodium Free Granular Flux removes non-metallic inclusions, hydrogen, sodium, calcium and lithium from liquid aluminium and aluminium alloys.

It is produced in both fine particle and granular form. SCOT-MAG reacts quickly and efficiently to remove sodium, lithium and calcium from molten aluminium and aluminium alloys, as well as from refractory furnace linings.

Sodium levels less than 1 ppm in high Mg aluminium alloys are attainable in the casting.

Sodium Free Granular Flux removes various nonmetallic inclusions such as oxides, carbides and borides, and enhances degassing when injected.

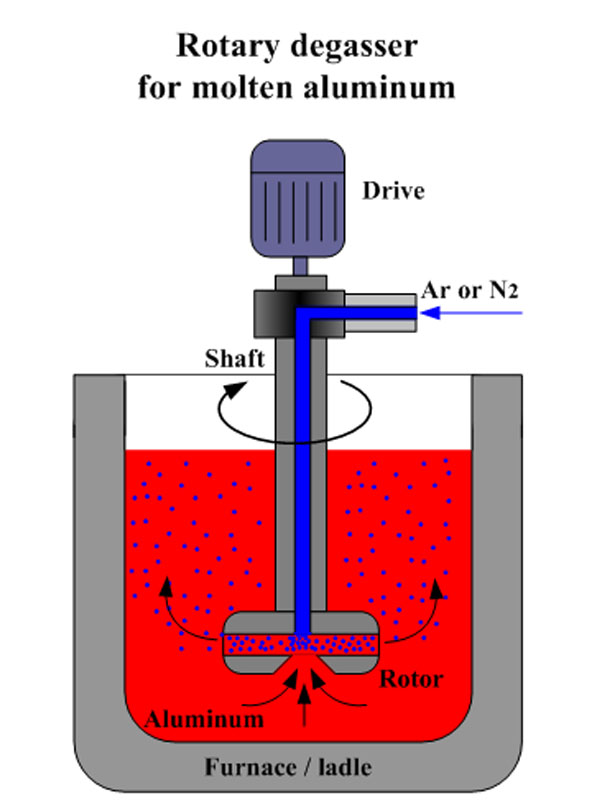

Mixed gas purification method. A mixture of chlorine and nitrogen is used to purify molten aluminum. Its role is to remove hydrogen and separate oxides on the one hand, and to remove some metal impurities (such as magnesium) in aluminum on the other. The commonly used composition is 90% nitrogen + 10% chlorine. . There are also 10% chlorine + 10% carbon dioxide + 80% nitrogen. This effect is better, carbon dioxide can diffuse chlorine and nitrogen well, which can shorten the operation time.

The gas in aluminum alloy melt is mainly hydrogen (its volume fraction is about 80%~90%), followed by nitrogen, oxygen, carbon monoxide and so on.

Although the content of hydrogen in aluminum alloy melt is not very high compared to other metals, hydrogen is almost insoluble in solid aluminum, and its solubility in liquid aluminum is very large, and it increases with the increase of temperature.

The solubility of hydrogen on the solid phase line is 0.65 mL and 0.034 mlL per 100 g of liquid aluminum hydrogen content (H at 0.1 MPa), that is, the difference in solubility of hydrogen in the solid-liquid phase is about 19.1 times, due to the difference in solubility , Hydrogen tends to escape from the melt. When the hydrogen pressure is greater than the surface tension and hydrostatic pressure, bubbles are formed, and then pores are formed in the casting or ingot.

Therefore, in the purification treatment of aluminum alloy melt, the main problem is that the hydrogen content of aluminum alloy is high, and the aluminum melt degassing purification technology can not meet the production requirements of high-quality aluminum alloy components.

Generally, there is 0.1 to 0.2 mL of hydrogen per 100 g of aluminum, and aluminum alloy products used in the aerospace industry have higher quality requirements.For example, aluminum materials for aircraft parts require no more than 0.06 ml of hydrogen per 100 g.

No Comments