24 8月 Mitsubishi Aluminium Ceramic Foam Filter

Mitsubishi Aluminium Ceramic Foam Filter can effectively remove various inclusions in the aluminum water with a fineness of micrometers.

Make the aluminum water into a smooth laminar flow, which is conducive to flushing, good mechanical strength and chemical stability, and superior aluminum water erosion resistance.

Strictly controlled hole size and through-hole rate can obtain a stable filtering effect.

There is a sealing ceramic fiber liner around the foam ceramic filter plate, which helps to seal the filter in the filter box and ensure that there is no side flow of molten metal.

The filter used by Mitsubishi Aluminium in cast aluminum can effectively remove various fineness of micro-inclusions in the aluminum water, making the aluminum water a smooth laminar flow, which is very suitable for filling.

It has good mechanical strength and chemical stability, as well as excellent aluminum cleaning.

Strictly control the pore size and through-hole ratio to achieve stable filtration.

There is a sealed thermal expansion ceramic fiber gasket around the foam ceramic filter plate, which helps the filter plate to be sealed in the filter box to ensure that no metal liquid is bypassed.

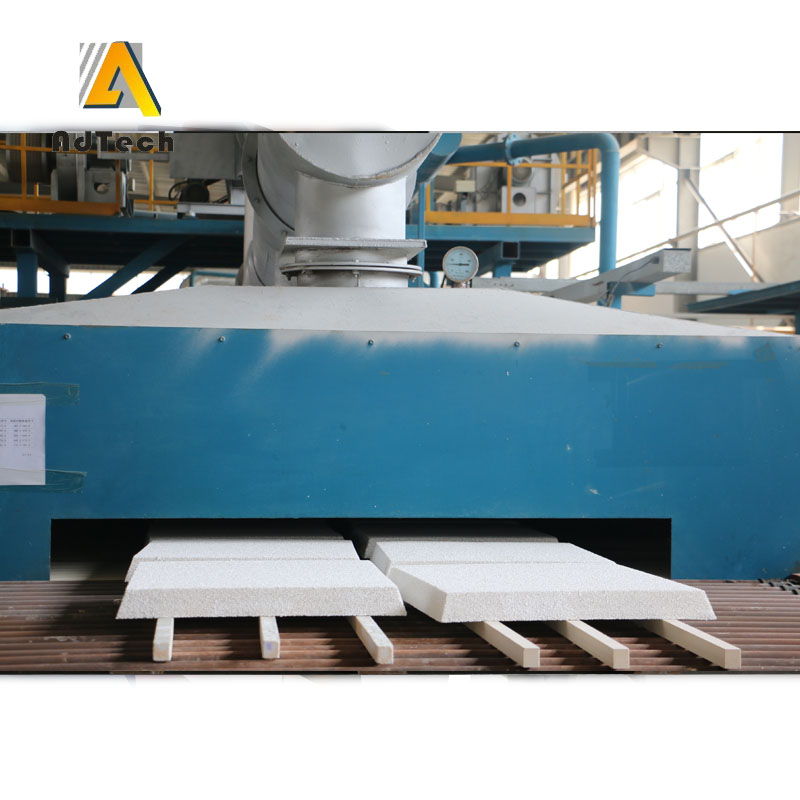

Parameters of Mitsubishi Aluminium Ceramic Foam Filter in aluminum and aluminum alloy production

178×178×50mm, 230×230×50mm, 305×305×50mm, 381×381×50mm, 432×432×50mm, 508×508×50mm, 584×584×50mm,

There are mainly seven kinds of foam ceramic filter plate products.

Mitsubishi Aluminium Ceramic Foam Filter User Manual

1. Check and clean up the debris on the surface of the filter box, keep the filter box clean and free from damage.

2. Gently put the filter plate into the filter box, and press the sealing ring around the filter plate with your hands to prevent the aluminum liquid from flowing or floating.

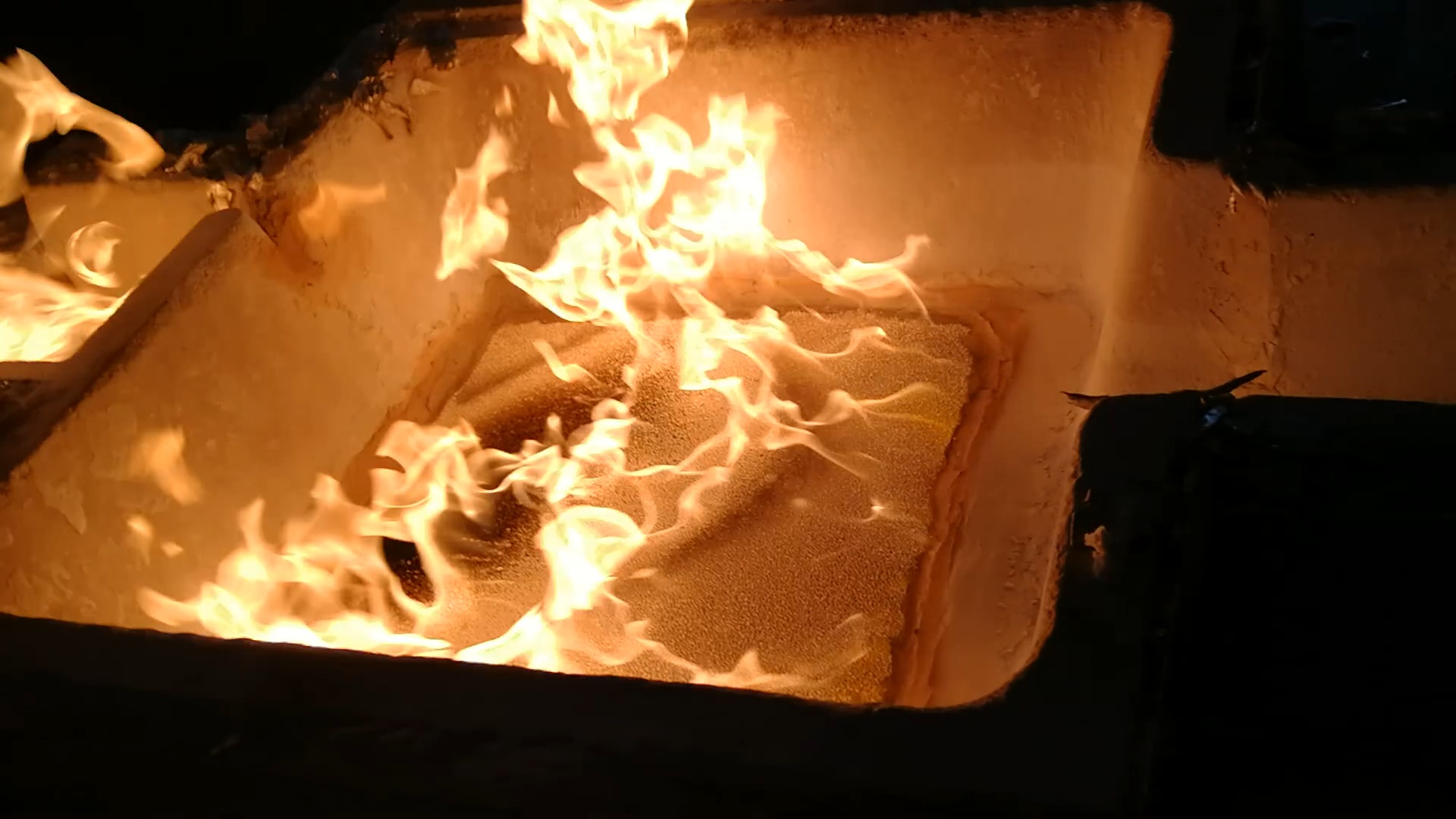

3. Preheat the filter box and the filter plate evenly to make it close to the temperature of the molten aluminum. The preheating temperature of the filter plate shall not be lower than 260℃. Preheating removes the absorbed moisture, helps the initial opening of the filter holes, and prevents some holes on the filter plate from being blocked due to thermal expansion and contraction. Electric heating or gas heating can be used for preheating. Normal heating is 15-30 minutes.

No Comments