23 4月 Melting Aluminum Honeycomb Filter

Melting Aluminum Honeycomb Filter is mainly used to filter aluminum and aluminum alloys in foundries and foundries. Due to its excellent resistance to corrosion and corrosion of molten aluminum, it can effectively remove inclusions, reduce trapped gas, provide laminar flow, and significantly clean the filtered metal.

Cleaner metals can produce higher quality castings, less scrap and fewer inclusion defects, all of which help increase profits.

Using this new technology, a variety of foam ceramic materials have been produced. Although most research work has focused on materials such as engineering ceramic oxides, alumina, cordierite, mullite, and zirconia, many other ceramics can also be foamed.

The foam made of alumina ceramics has higher strength.

The thermal insulation performance is almost as good as that of fiber products, and it also provides a completely fiber-free and dust-free working environment.

When using zirconia, the operating temperature can be as high as 2000°C.

The foams we use for ceramic filters meet the highest quality standards and have excellent uniformity.

They have a variety of pore sizes and can be used for aluminum in ceramic filters.

We have two types of ceramic foam filters-pal and ceramic foam filters-pzr.

For more information about Ceramic Foam Filters For Casting, please send an email to sales@adtechamm.com.

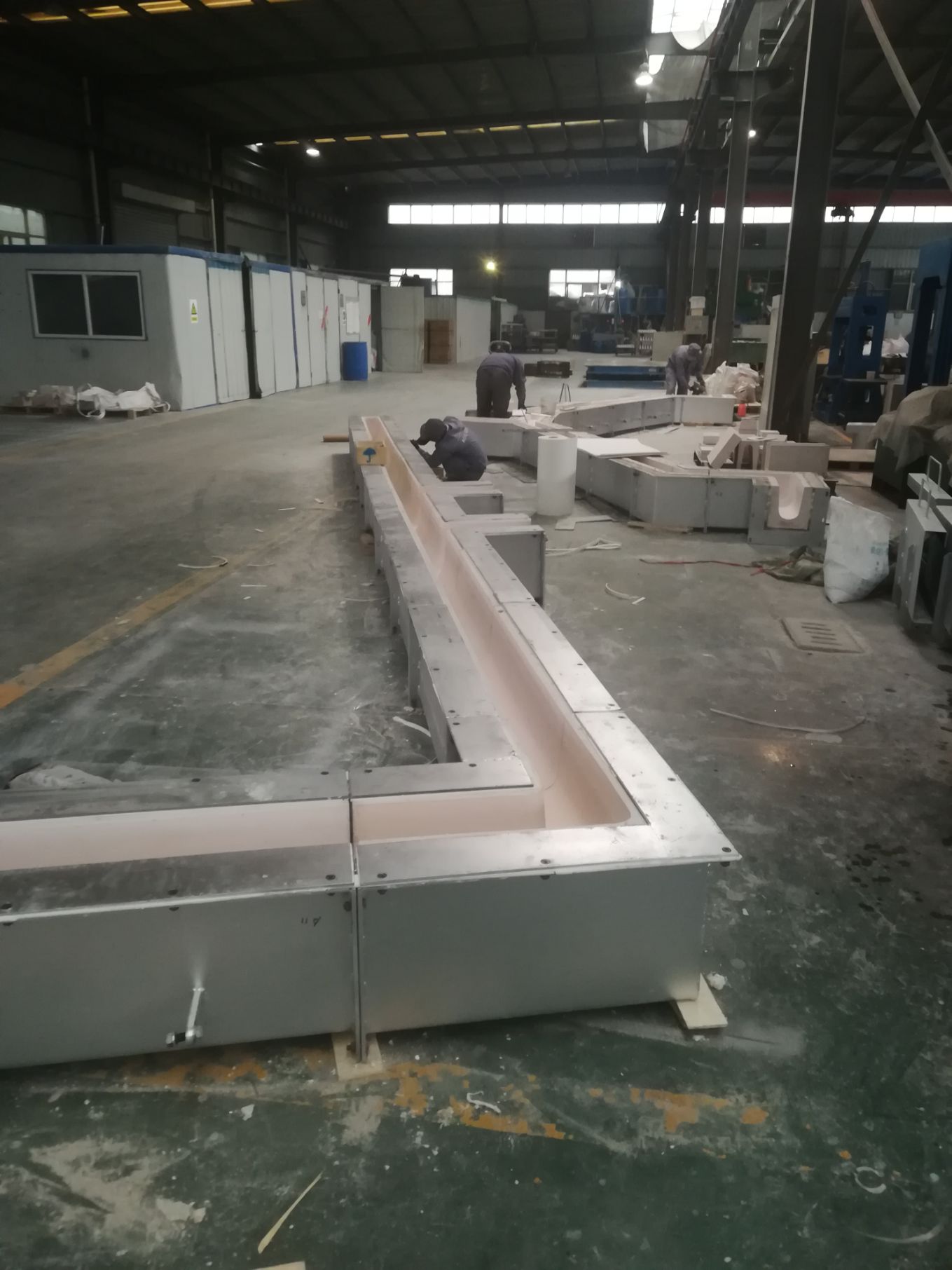

Melting Aluminum Honeycomb Filter supplier provides a new type of ceramic foam filter material developed for many years.

It is a ceramic slurry composed of alumina and chromium oxide, formed by polyurethane foam, and then dried and sintered.

The porosity is as high as 80%~90%. It is characterized by easy use, good filtering effect, no high pressure head during filtering, and low price.

However, ceramic foam is brittle and easily damaged, and usually only used once. In order to improve the filtering effect, a two-stage filtering method can be used.

Melt filtration is also an important object for the development of aluminum melt purification treatment.

Ceramic foam filter Dimension

660x660x50(26 inch)

584x584x50(23 inch)

508x508x50(20 inch)

432x432x50(17 inch)

381x381x50(15 inch)

305x305x50(12 inch)

228x228x50(9 inch)

178x178x50(7 inch)

Ceramic foam filter Pore Size (PPI): 10/20/30/40/50/60

30ppi 40ppi Foundry Filter is the most commonly used ceramic foam filter in the aluminum casting industry.

Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.

No Comments