01 7月 Marubeni Ceramic Foam Filter

Marubeni Ceramic Foam Filter captures molten aluminum inclusions in the aluminum melting and casting workshop, which is essential to keep the aluminum ingots clean. This ensures the quality and productivity of downstream processes such as forging, extrusion, and rolling.

Korean Aluminium puts the ceramic foam filter in the CFF unit, and the aluminum and aluminum alloy are sent to the hot top casting platform through the washing tank. Casting machines produce various aluminum rods.

Korean Aluminium purchased filter castings through sales@adtechamm.com and introduced the following advantages

1. Ceramic Filter has excellent resistance to corrosion and corrosion of molten aluminum, and can effectively remove inclusions.

2. Reduce residual gas, provide laminar flow, and clean the filtered metal.

3. Clean metal can produce higher quality castings.

4. Less waste and fewer inclusion defects, all of which help increase profits.

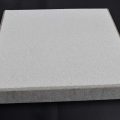

The liquid aluminum filter box is a special aluminosilicate filter box for the aluminum industry. We usually call it foam ceramic filter box, which is a filter box made of steel shell and aluminum silicate lining.

During the filtration process, the aluminum liquid passes through the ceramic foam filter plate and flows along the zigzag channel and the gap between the filter plate.

The impurities in the aluminum melt are in contact with the surface of the filter plate channel under the effects of deposition, inertia and retention.

Impurities stay firmly on the filter plate under pressure, friction, surface adsorption, etc.

Korean Aluminium Said that for aluminum alloy profile manufacturers, the advantages of using Marubeni Ceramic Foam Filter to purify aluminum

1. Improve extrusion efficiency

When the filter plate was used to purify the 6063 alloy extruded billet, the specific die was tracked and it was found that the extrusion speed was increased by about 20%, and the productivity was increased by nearly 15%.

2. Extend the life of the mold and reduce the number of mold maintenance.

3. Reduce stress

The 6063 alloy melt was purified with a filter plate, and it was found that its extrusion force was more than 3% lower than the unfiltered extrusion force.

4. Greatly improve the surface quality of aluminum profiles.

from above. In terms of reducing production costs and improving product quality, the use of ceramic foam filter plates to purify aluminum melt has great advantages.

Guyana Aluminum Company notified Guyana aluminum casting manufacturers about the purchase of Chinese filter plates by email sales@adtechamm.com.

No Comments