07 11月 Internal structure of alumina ceramic foam filter

Internal structure of alumina ceramic foam filter

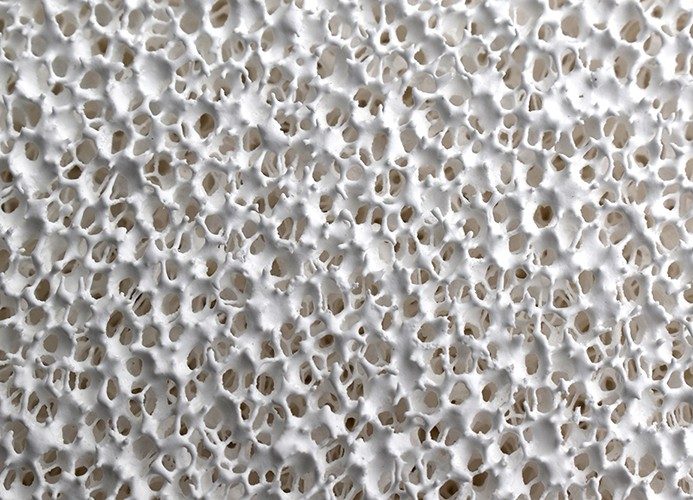

The internal structure of alumina ceramic foam filters usually consists of two parts: the substrate and the coating.

Internal structure of alumina ceramic foam filter

1. Substrate:

It is the main part of the alumina ceramic filter plate, which is made of high-purity alumina particles mixed with binders such as silicates and magnesium oxides.

The role of the substrate is to provide mechanical strength and load-bearing capacity to ensure the stability and durability of the filter plate.

2 Coating:

The coating is a key part of the alumina porous ceramic filter plate, which is made of nanometer-sized alumina particles and binders.

The coating is evenly applied to the surface of the substrate to form a dense film. The role of the coating is to provide a filtration function, which can capture and filter out small particles, suspended solids, gases, and other impurities to ensure filtration efficiency.

During the manufacturing process, the aluminum oxide ceramic filter plate undergoes high-temperature sintering treatment, which allows the matrix and coating materials to fully sinter together, forming a strong and dense ceramic filter plate. At the same time, high-temperature sintering can also eliminate impurities and pores in the material, improve the purity and density of the material, and further enhance the performance and service life of the filter plate.

Summary: The internal structure of alumina ceramic filter plates consists of two main parts – the substrate and the coating. The combined effect of the substrate and the coating is to provide mechanical strength, load-bearing capacity, and filtration function to ensure filtration efficiency and service life.

No Comments