26 2月 High Quality Ceramic Filter

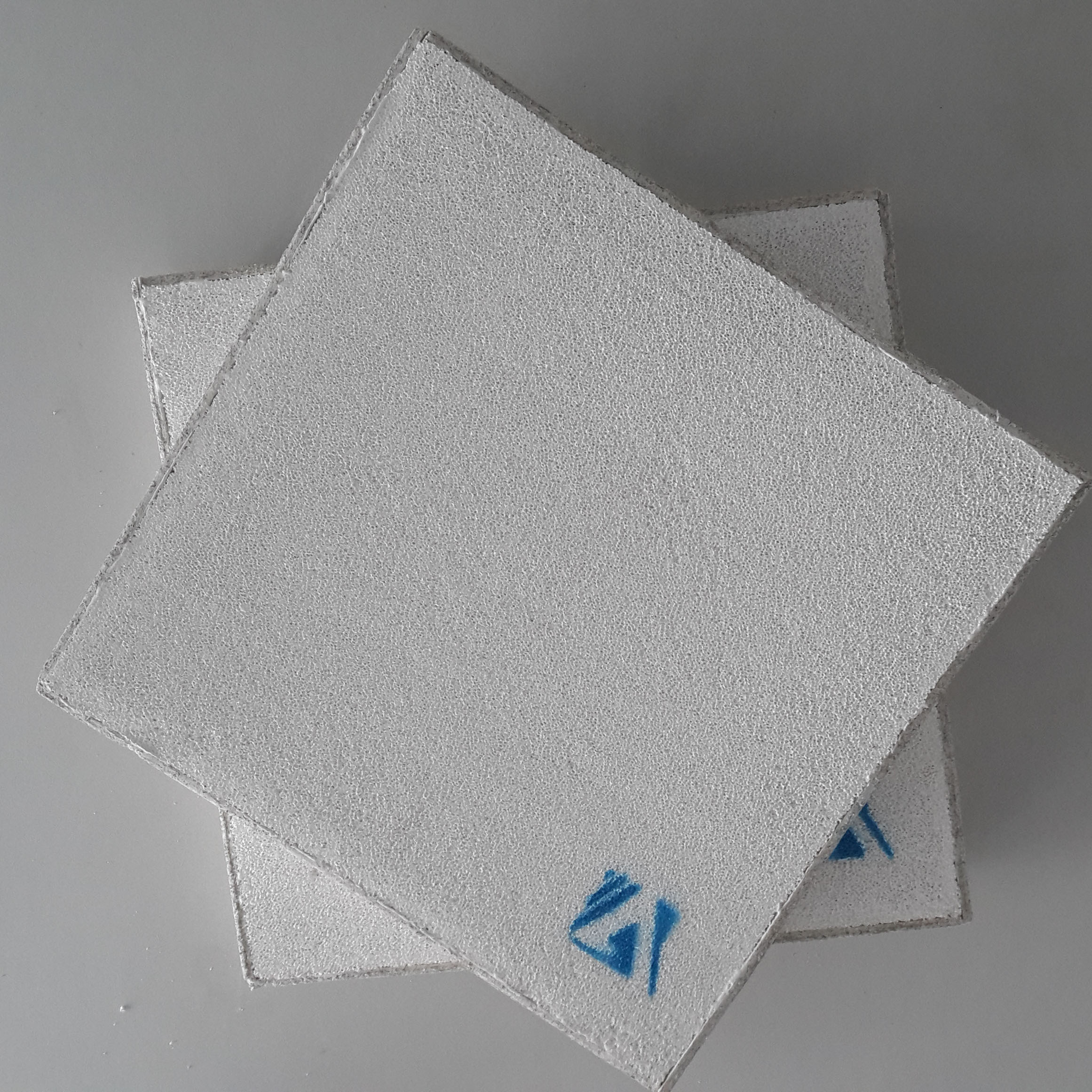

High Quality Ceramic Filter can effectively remove the large inclusions in the molten aluminum, and can remove the small inclusions of a few microns in size that are incapable of conventional processes in the molten aluminum.

Reduce the hydrogen content in molten aluminum.

Through adsorption, the content of harmful elements in molten aluminum (Na.k) can be removed.

Generally speaking, the selection of the Ceramic Foam Filter should take into account the requirements for the quality of the finished product, the flow rate of the molten aluminum in the launder, the total amount of the filtered molten aluminum, and the cleanliness of the molten aluminum itself.

Causes and Solutions of Defects in Aluminum Foil Rolling

1. The filtering, degassing and slag removal of the aluminum melt before casting are not thorough, and the slag inclusions such as alumina and slag are brought into the aluminum melt and finally into the billet.

2. When replacing the High Quality Ceramic Filter, alumina, slag and other slag inclusions are brought into the aluminum melt.

3. The purity of the aluminum melt is too poor, and there are too many non-metallic foreign objects, and the degassing and slag removal cannot be completed.

solution

Use a more High Quality Ceramic Filter to filter the aluminum melt (two-stage filtration of foam ceramics with high adsorption capacity). Change the replacement method of the filter.

Choose good primary aluminum and scrap.

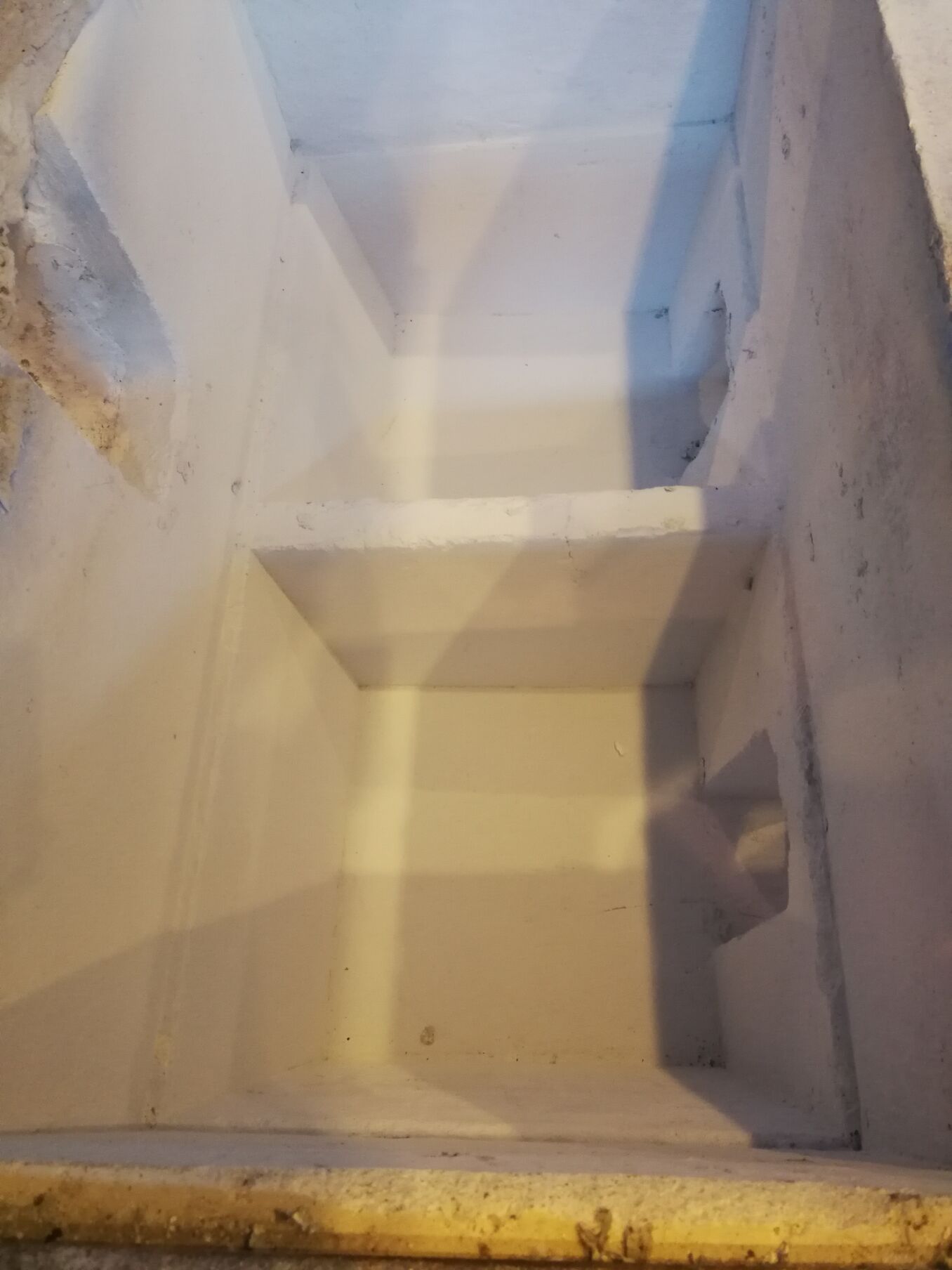

From pouring to solidification, the casting alloy liquid will shrink macroscopically or microscopically at the place where it solidifies.

This kind of macroscopic shrinkage caused by shrinkage is visible to the naked eye, and is divided into concentrated shrinkage and dispersive shrinkage.

The apertures of the concentrated shrinkage holes are large and concentrated, and are distributed on the top of the casting or at the hot joints with a thick section.

The dispersive shrinkage cavities are scattered and fine, most of which are distributed in the casting axis and hot joints.

The microscopic shrinkage cavities are difficult to see with the naked eye, and most of the microscopic shrinkage cavities are distributed under the grain boundary or between the dendrites of the dendrites.

No Comments