30 7月 Foundry Fluxes Meaning

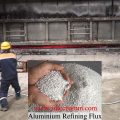

Foundry Fluxes Meaning is a granular refining agent used in aluminum plants, fluorine-free and sodium-free to remove non-metallic inclusions in aluminum and aluminum alloys and alkali metals Na Ca and Li in the furnace.

It is used for the refining of 1 series to 8 series aluminum alloy and A356 hypoeutectic aluminum silicon alloy. Hexachloroethane can be added according to customer requirements. It can also be used for remelting and remelting coal refining of aluminum scrap with a relatively large amount of scrap aluminum.

Melting is a process in which a solid heats up and turns into a liquid with fluidity and starts to melt after the feeding is completed.

During the smelting process, it is necessary to ensure that the melting is fast and uniform, and the temperature near the flame is higher than 1200 ℃ in order to avoid local overheating and excessive temperature, which will cause serious oxidation of aluminum alloy and bring inconvenience to later product refining.

During the melting process, stir the unmelted charge into the aluminum liquid, so that it is almost completely immersed and stirred evenly to avoid local overheating.

The last element such as Mg immersed in the flame can not be directly heated and melted, and because the aluminum liquid is immersed in the raw materials, the temperature is lowered to keep the elements such as Mg and other elements melted at a relatively low temperature to reduce burning loss and improve combustion efficiency.

The aluminum alloy begins to melt at about 600 ℃, and the temperature is increased to 660 ℃. The melting temperature is controlled to not exceed 760 ℃. When the melting temperature exceeds 770 ℃, the oxidation of the aluminum alloy will increase hydrogen absorption and slag inclusion during the casting and solidification process. Coarse grains appear, reducing mechanical properties.

In order to reduce the oxidation of aluminum alloy in the melting process, 0.4%~0.5% of the covering agent is added during the melting process to protect the aluminum alloy surface oxide film from being damaged. The type of covering agent is similar to the chemical composition of the slag cleaning agent.

Foundry Fluxes Meaning is a granular refining agent used in aluminum plants, fluorine-free and sodium-free to remove non-metallic inclusions in aluminum and aluminum alloys and alkali metals Na Ca and Li in the furnace.

The temperature of the smelting process is controlled at 720 ~ 760 ℃. After the aluminum bond is melted, raw materials with higher melting point such as si element and Ti agent are added. Ti forms a heterogeneous crystal nucleus in the alloy to refine the structure and press it into the aluminum liquid. Melt, reduce burning loss.

After the aluminum ingot is basically melted, the easy-to-burn element Mg.Cu and other alloying elements should not be added too early to reduce the burning loss, nor too late to affect the diffusion and segregation. Close the furnace door and continue smelting.

After the smelting is complete, there are many scum on the surface of the aluminum alloy, mainly A1, O, and other oxides. These fine slags are heavier than molten aluminum, but after agglomeration, the specific gravity is light and floats on the surface. The surface needs to be cleaned.

The amount of slag cleaning agent is 0.2% ~ 0.5%. Add it and sprinkle it evenly on the surface of the molten aluminum and stir it evenly.

Put the slag on the furnace door, close the furnace door and let it stand. On the one hand, the slag cleaning agent has a heating effect and can melt the aluminum liquid adhering to the scum. After standing for a few minutes, the aluminum slag at the door of the furnace will be steadily pulled out.

Aluminum alloy smelting is a very complicated process. Due to the inconsistent burning degree of different elements, after the slag is removed, the aluminum liquid needs to be sampled for physical and chemical analysis before being transferred to the ladle to ensure that each element is within the qualified range before the water can be released into the ladle for removal. Qi is refined, otherwise it needs to be adjusted appropriately.

No Comments