13 9月 Foam Ceramic Filter Isal Aluminum

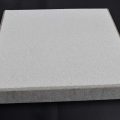

Foam Ceramic Filter Isal Aluminum has no debris falling off, effectively reducing aluminum liquid pollution.

The principle of adsorption is applied to the filter, which can effectively remove large inclusions in molten aluminum and effectively adsorb small inclusions.

Superior thermal shock resistance improves the erosion resistance of molten metal.

Fully automatic flow production, 3 kinds of calibration methods, accurate size, tight fit of the filter cup.

Improve the appearance and performance of the surface, and clean the aluminum liquid.

Foam Ceramic Filter Isal Aluminum-These filters are specially used for aluminum castings. Market-leading suppliers currently offer various sizes and thicknesses. You must choose the right one according to your requirements. If your requirements are not suitable for popular sizes, you can order custom sizes. In order to avoid re-oxidation of molten aluminum during the casting process, you can choose pressureless casting technology. It improves the manufacturer’s productivity and prepares the filter for the next high-volume shipment.

In the production of castings, the rejection rate of castings caused by casting defects such as non-metallic inclusions usually accounts for 50-60% of the total waste.

Inclusion defects not only greatly reduce the mechanical properties of the casting, but also adversely affect its processing performance and appearance.

The cleaning of liquid casting alloys and the reduction or elimination of various non-metallic inclusions are undoubtedly a very important technical measure for obtaining high-quality castings.

Filtering technology can effectively achieve the purpose of purifying liquid casting alloys.

According to news organizations reported earlier this month, at least three companies (including Swiss commodity trader Glencore and German Trimet Aluminium) have expressed interest in buying Rio Tinto’s aluminum assets in Iceland, Sweden and the Netherlands at a price of up to 350 million U.S. dollars. Reuters quoted sources as saying that Liberty House is also interested in these assets. In addition to the ISAL aluminum smelter in Iceland, Rio Tinto also sold a 53% stake in the Dutch anode facility and a 50% stake in the Swedish aluminum fluoride plant, both of which are key materials used in the aluminum smelting process.

After Norsk Hydro, a Norwegian aluminum company, withdrew from the acquisition in September last year, Rio Tinto restarted the sale of these assets in early July and blamed it on the delay in obtaining approval from the European Commission. The source said that given that Hydro is already a major participant in the European aluminum industry, the European Commission may have competition concerns.

But why did Rio Tinto sell these assets in the first place? Any competent trader knows that you sell high and buy low—in this case based on the LME price—which is the exact opposite of what Rio Tinto and Alcoa have done recently. In fact, Rio Tinto last year sold the Dunkirk smelter, the largest aluminum smelter in Europe, located in northern France. The transaction was agreed with Freedom House and is valued at 500 million U.S. dollars. Just before that, in December 2016, Rio Tinto’s smaller Lochaber smelter in Scotland was again acquired by Liberty House. At the same time, Alcoa has been trying to sell its smelter in Spain.

But more interesting is that Rio Tinto acquired Alcan for US$38 billion in 2007, when aluminum prices were at a 20-year high. In contrast, the current trend of the LME is historically low prices.

No Comments